![]() 24-Stunden-Kundenhotline +86 15395181370

24-Stunden-Kundenhotline +86 15395181370

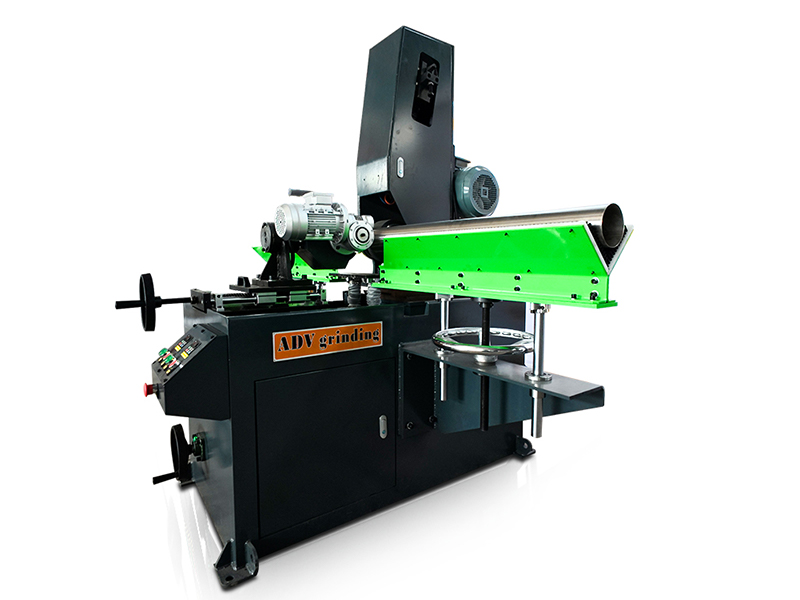

ADV® 106 Rohr-Poliermaschine

Details zum Produkt

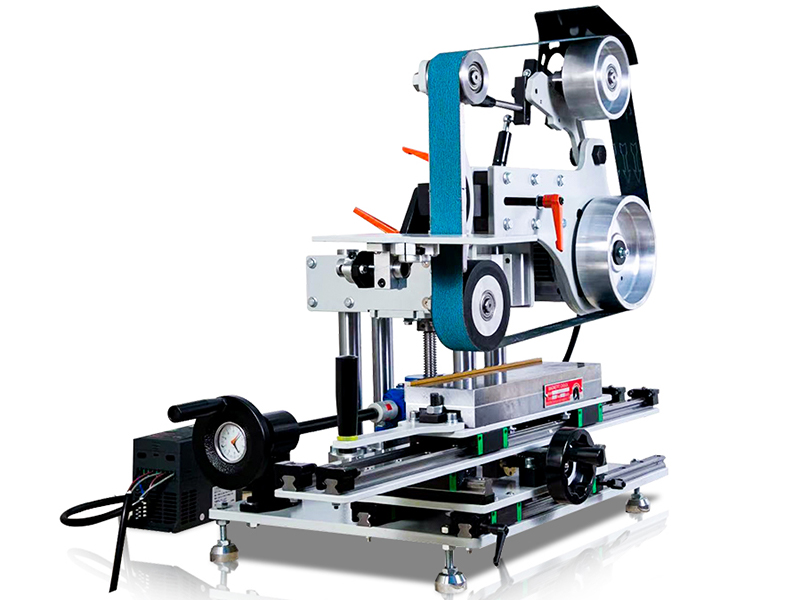

Tube Pipe Polisher (polish tubes in stainless steel)- Highly customizable

Straight Pipe Polishing – Pipe Finishing .Automatic pipe sander with feeding system.

- Quality and productivity: straight tube, multi-station wet/dry finishing up to 165mm.

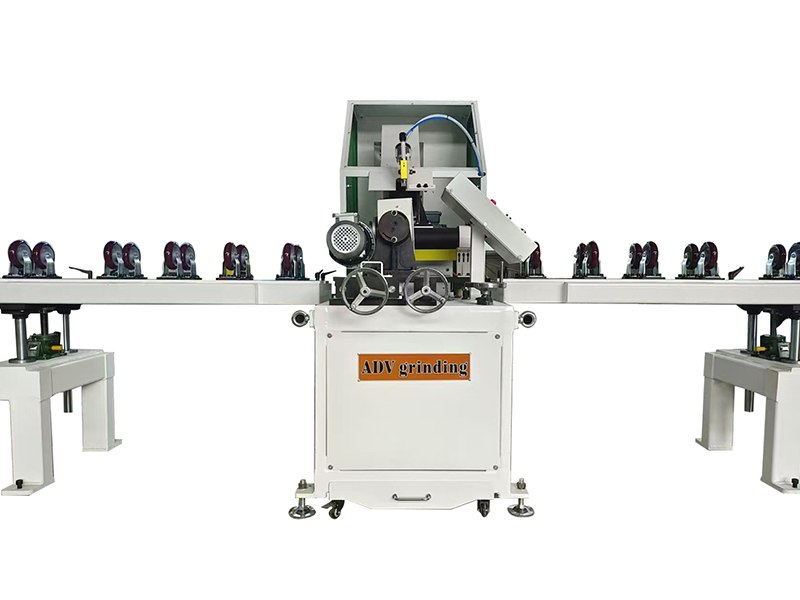

- The 106-1 round tube, multi-station wet or dry finishing machine, available with 1 stations (106-1), is equipped with the centerless system and enables a faster finishing job than single–station machines.

- The tube pipe polisher can accommodate tubes/pipes with diameters from 38mm to 165mm and lengths from 600 to 6000mm, suitable for a variety of applications. It uses a 100 x 2000mm sanding belt or a 50x 300mm polishing wheel, and the surface of the round tube/pipe can be polished to a brushed or mirror effect.

- Automatic work set-up and control of all the information about the tube pipe finishing are done in a mobile panel with an integrated touchscreen. Completely independent finishing stations. Final finish in only one go.

- The wet-operation system enables faster cooling of the tube as well as the possibility of working different types of metal simultaneously.

- this centerless tube belt sander polisher comes with variable speed to adjust work piece speed according to diameter

Large selection of pipe polishing and sanding machines. Automatic tube pipe polisher and tube grinding with feeder. Pipe belt sander. Centerless Pipe Sander.

Two models of Centerless pipe deburring machines to choose from: white and black

Specifications:

Model: ADV 106-1

Available tube diameter range: 38-165 mm

Grinding head motor power: 7.5 kW

Grinding head motor speed: 0-30m/s

Feeding motor power: 0.75 kW

Feeding speed: 1-5 m/min

tube pipe polisher Abrasive belt size: 100*2000 mm

Polishing wheel size: 50*300 mm

Machine dimension: 1650*1000*2050 mm

Available abrasives: Abrasive belt, flap wheel, Nylon, Hemp wheel and cloth wheel

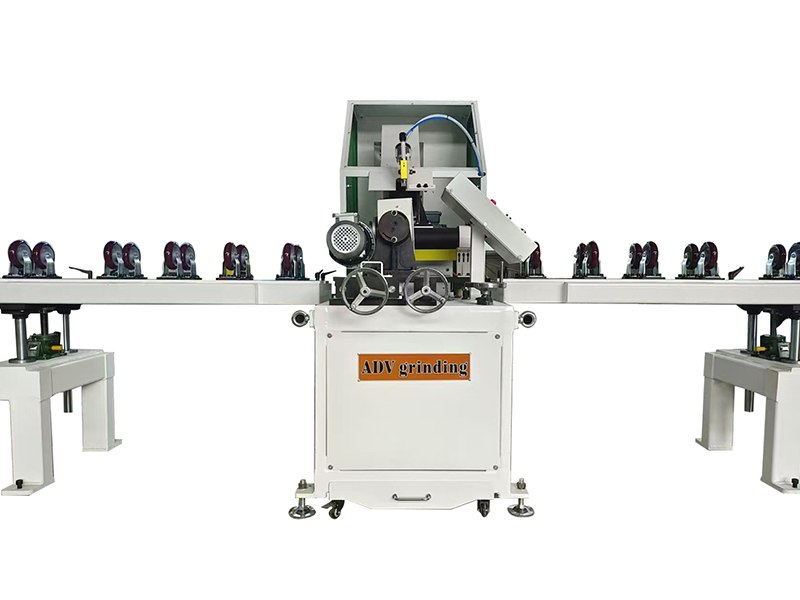

- Quality and productivity: straight tube(pipe), multi-station wet or dry finishing up to 500mm.

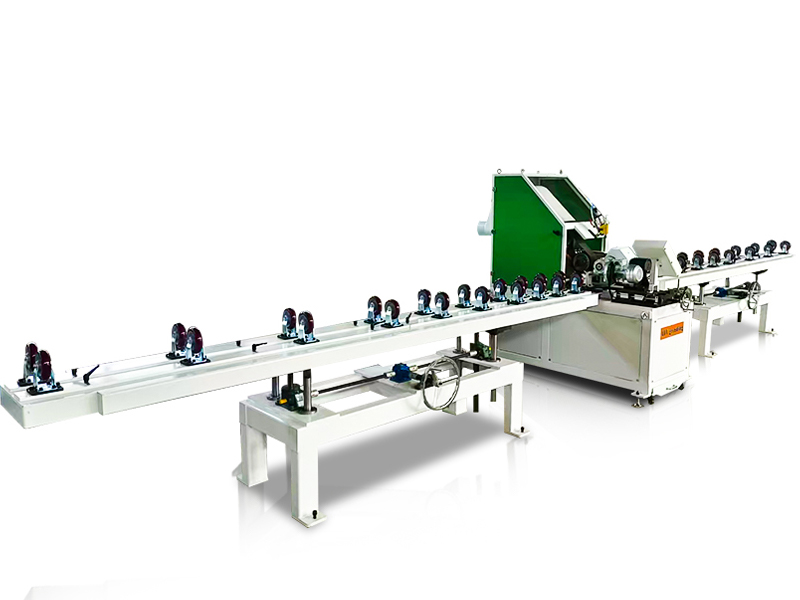

- ADV 106 Series polisher is centerless polishing machine for the Tube/pipe. It can be equipped with 1-10 sets of grinding heads by different requirements, is equipped with the centerless system and enables a faster finishing job than single–station machines.

- Automatic work set-up and control of all the information about the tube finishing are done in a mobile panel with an integrated touchscreen. Completely independent finishing stations. Final finish in only one go.

- The wet-operation system enables faster cooling of the tube as well as the possibility of working different types of metal simultaneously.

- Highly customizable.

Specifications:

Model: ADV 106-6

Effectively polished diameter: 20-500 mm

Belt size: 2000*150 mm or custmized

Polishing wheel size: 300*50 mm or custimized

Feeding Speed: 0.5-5 m/min, or custimized

Wet /Dry polishing both available.

Explore additional videos showcasing pipe polishing machines here.

Spitzenlos pipe polishing MACHINE FAQ

How does a centerless grinder work?

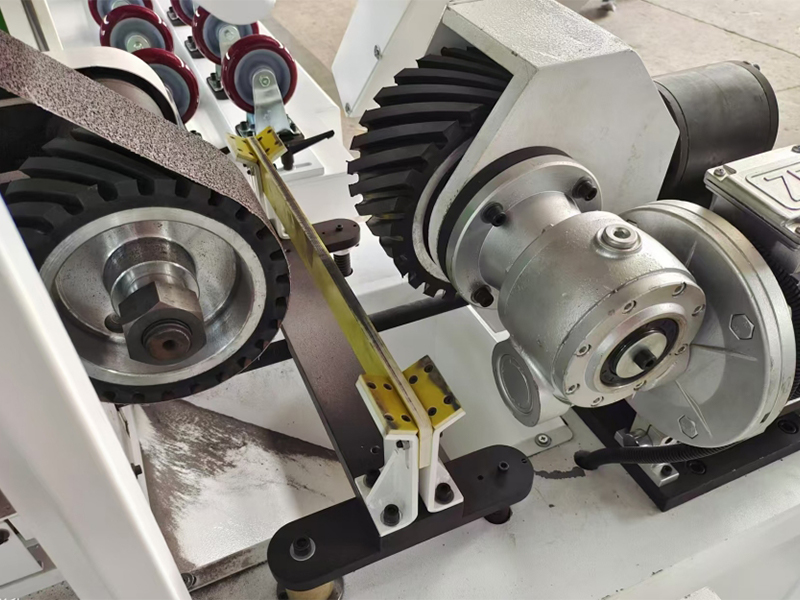

A centerless grinding machine uses two wheels – a grinding wheel and a regulating wheel – to support and rotate the workpiece. The grinding wheel removes material from the workpiece’s outer diameter, while the regulating wheel controls the rotational speed and feed rate.

centerless pipe sanding machine table is covered with anti-friction plastic material

What are the advantages of centerless grinding equipment?

Centerless grinding offers several advantages, including high precision, increased productivity, reduced setup time, and the ability to process long, slender workpieces with tight tolerances.

What industries commonly use centerless grinding machines?

Centerless grinding machines are widely used in industries such as automotive, aerospace, medical devices, electronics, and manufacturing, where precision machining of cylindrical components is required.

Are there different types of centerless grinding machines?

Yes, centerless tube pipe polisher come in various configurations, including through-feed, in-feed, and end-feed centerless grinders, each designed for specific applications and workpiece geometries.

Find high-quality centerless tube polishing machines for various applications. Efficient and reliable, perfect for metalwork and vehicle accessories.

Weitere Produkte

Leistungsstarke Bandschleifmaschine mit stabilem Maschinengestell, empfohlen für: Glätten von Graten auf Metall, Anfasen von Kanten zum Schweißen, Endbearbeitung von Gussteilen u.a.

Die handgeschobene Bandschleifmaschine (Bandschleifmaschine für Metallplatten) eignet sich zum Schleifen von großen Werkstückschweißnähten, Oberflächen, Langbandschleifmaschinen.

Das rotierende Rad der Bandschleifmaschine 116-9 ist aus reinem Aluminium gefertigt und zeichnet sich durch Präzision und Ausgewogenheit aus.

Die Maschine ist für das externe und interne Schleifen und Polieren von Schüsselschächten konzipiert. Es hat VFD-Steuerung, SPS-Steuerung und CNC-Steuerung nach Ihren unterschiedlichen Anforderungen an die Produktivität. Der verfügbare Standarddurchmesser für den Tank ist 300mm-3000mm oder kundenspezifisch. Die Schüsselkopf elliptische Poliermaschine ist weit verbreitet im medizinischen Bereich, Chemie, Umweltreinigung, Lebensmittel, Kochgeschirr, Getränke und Wasserfilter, etc.