![]() Línea directa de atención al cliente 24 horas +86 15395181370

Línea directa de atención al cliente 24 horas +86 15395181370

ADV® 508-RWr

Detalles del producto

The Video Of The 508 RWr Series Deburring Machine

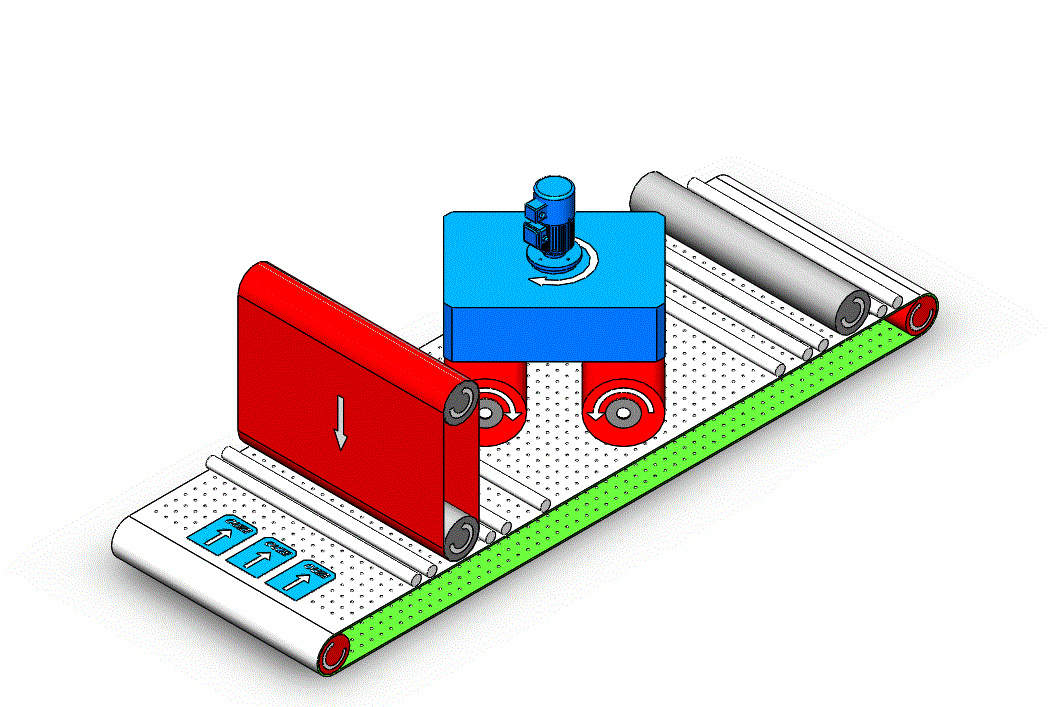

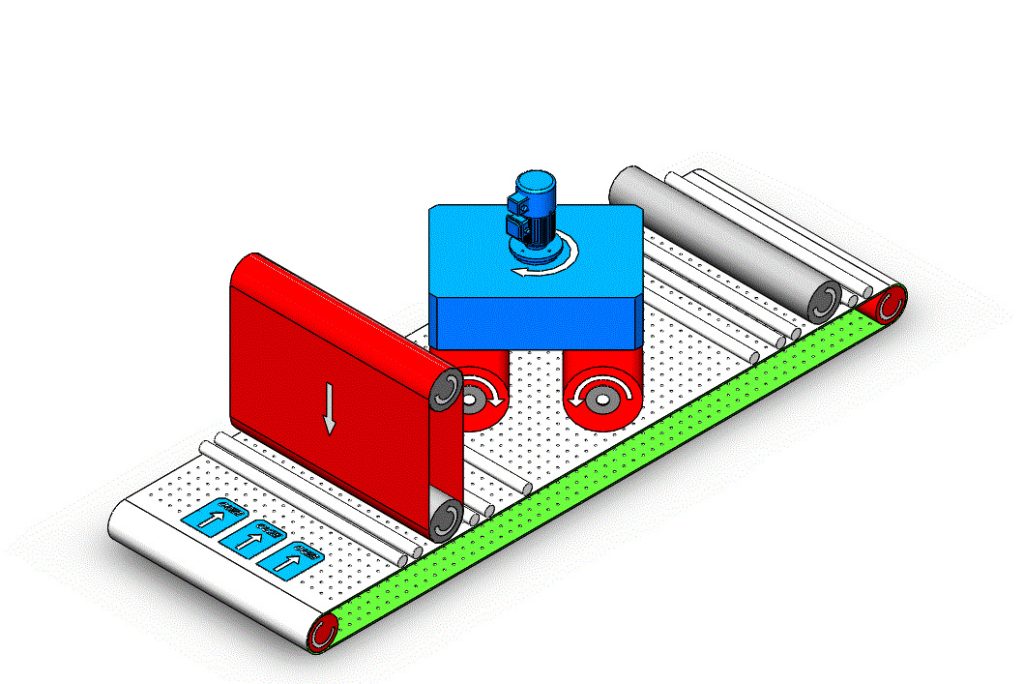

- In the first station – Grinding Belt(R station) of the finishing machine,burrs and imperfections are removed with a grinding belt, resulting in a flat, burr-free surface.

- After grinding,the Multicepillo(estación W), que garantiza un acabado perfecto de su producto. Los seis cepillos proporcionan un acabado no direccional y redondean los bordes con un radio de más de 2 mm, lo que confiere al producto un aspecto duradero y de alta calidad.

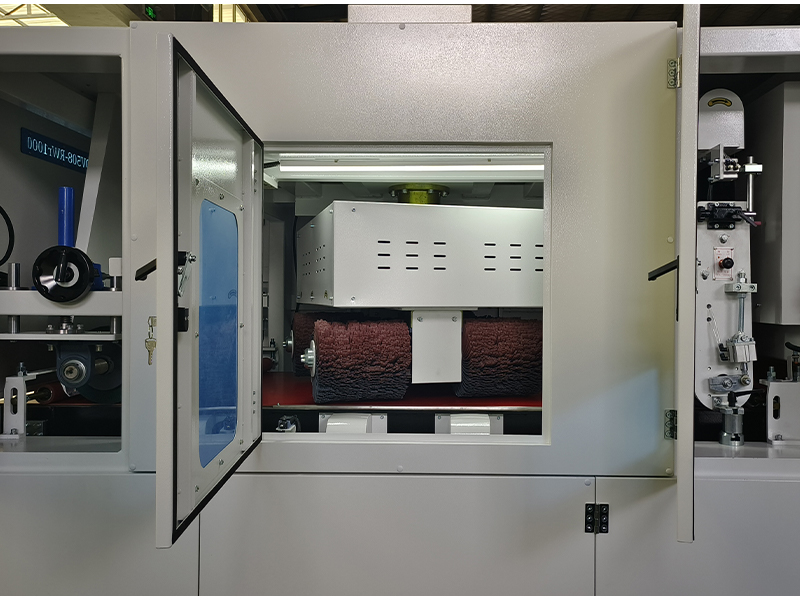

- The 3rd station Cepillo de rodillo (for r station), The roller brush inside the desbarbadora contacts the surface of the workpiece through the high-speed rolling bristles, and uses the elasticity and friction of the bristles to remove burrs and uneven areas on the workpiece surface.508 RWr Deburring Machine offers the possibility for full ERP control and seamless integration into automated production processes.

Wide belt & Rotary brush & Roller Brush

Metal finishing machine for brushing and polishing

Deburring & Polishing

No.3, No.4 Finishing

Hairline Finishing

Desbarbadora Parámetros básicos

Anchura disponible:

300/450/630/800/1000/1300/1500/1600 mm

Espesor disponible:

0,5-100 mm

Velocidad de alimentación:

0,5-8 m/min

Rotation speed of rotary brush:

9-21 r/s

Rotary brush size:

300*300 / 300*400 mm

Rango de redondeo de bordes:

R 0,1-1,0 mm

Mesa de trabajo:

900 - 980 mm

Tamaño mínimo de procesamiento:

30*30 mm (magnético)

50*50 mm (Vacío)

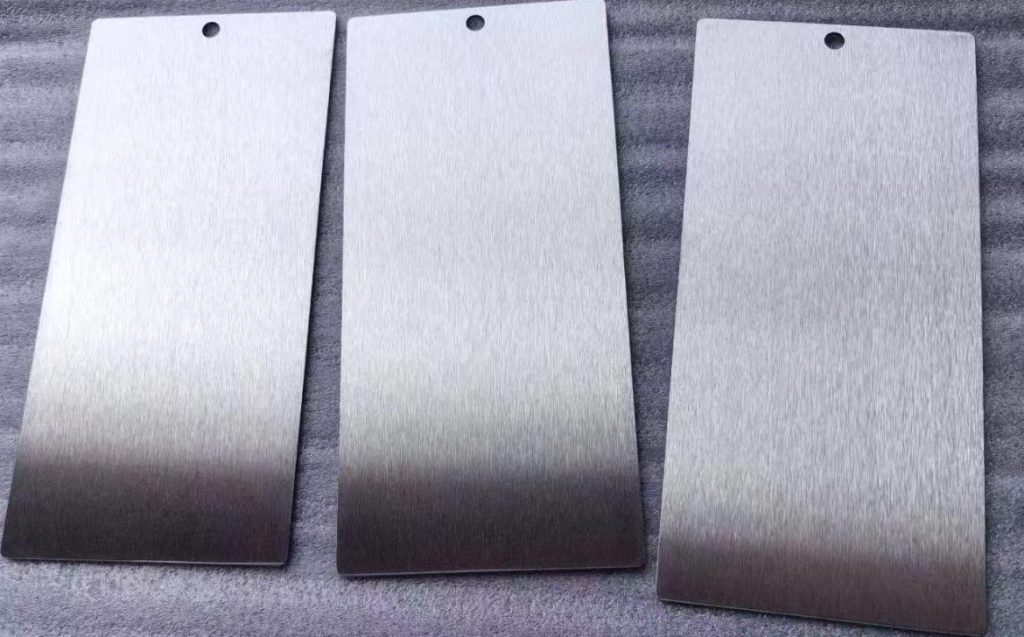

Finished product after deburring

508 RWr Deburring Machine FAQ

¿Pueden desbarbarse, redondearse los bordes y acabarse las superficies con una sola máquina o proceso?

Yes, deburring(wide grinding belt), edge rounding(rotary brush), and surface finishing(roller brush) can all be done by a single machine, the ADV® 508RWr. This 3-stage machine is single-sided and can even process sheet metal parts as small as 0.5 x 0.5mm. The 3 stages are comprised of a grinding belt for deburring, rotary brushes for edge rounding and a fleece belt for surface finishing.

What materials are suitable for ADV® 508RWr desbarbadora de chapa?

The ADV® 508RWr can process a wide array of metal alloys.These alloys include steel,aluminum,brass,copper,titanium,stainlesssteel and even specialty alloys.

¿Por qué es importante eliminar el óxido láser de las piezas metálicas?

El óxido láser se crea a lo largo del borde de corte cuando se corta con un láser alimentado por oxígeno. Este óxido láser a lo largo del lateral de las piezas impedirá que se adhiera cualquier revestimiento de pintura y dificultará la soldadura. Por lo tanto, la eliminación del óxido láser a lo largo de los bordes de corte mejorará en gran medida los procesos posteriores como la pintura y la soldadura.

Why does the automatic metal deburring machine use a roatary brush to round the edges of metal sheets?

Thanks to the rotary brushes of the ADV® 508RWr, uniform edge rounding for sheet metal can be achieved in a single pass. These rotary brushes can achieve an edge rounding result of up to 2 mm along all edges for a wide variety of metal alloys.

Más productos

508 M300 El desbarbado manual es necesario para productos especializados o tiradas de bajo volumen. Los fabricantes pueden saltarse el a veces largo proceso de programación de una máquina automatizada. También es una forma mejor de garantizar un acabado liso en una pieza que es demasiado frágil para un equipo semiautomático.

El objetivo del acabado es mejorar la calidad y el atractivo visual de las piezas de chapa metálica, al tiempo que contribuye a su protección. Garantiza un acabado uniforme y puede ayudar a mejorar la adherencia de revestimientos, pintura u otros materiales sobre la superficie.

Con las avanzadas máquinas de acabado de ADV, puede aplicar diversos acabados a sus piezas de chapa metálica. Mediante el uso de las bandas abrasivas adecuadas en combinación con la velocidad apropiada, terminar sus piezas de chapa metálica a sus preferencias, como con un acabado lineal o un acabado no direccional.

Rr Máquina de acabado de metales para cepillar y pulir.El acabado de piezas de chapa metálica se refiere al proceso de redondear y refinar las superficies de las piezas de chapa para darles un aspecto suave y estéticamente atractivo. eliminando imperfecciones, rebabas, bordes ásperos y otras características indeseables de la superficie.