![]() Línea directa de atención al cliente 24 horas +86 15395181370

Línea directa de atención al cliente 24 horas +86 15395181370

Visión global

Maquinaria de ingeniería de precisión

Soluciones de productos de acabado metálico que dan forma a su éxito

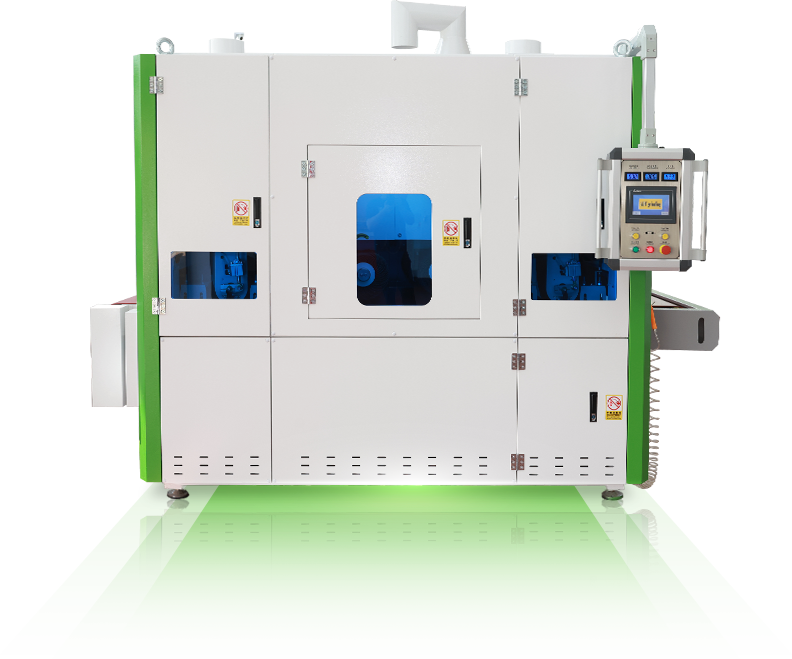

Desbarbadora

- Máquina de desbarbado y pulido de metales - Las rebabas no sólo afectan al aspecto de las piezas, sino que también reducen su funcionamiento y seguridad. El desbarbado es importante en el mecanizado porque las piezas metálicas se someten a varios pasos como el corte, el estampado y el fresado durante la fabricación.

- Con ADV Las máquinas de desbarbado y pulido procesan eficazmente los bordes de sus piezas, chapas y placas metálicas, eliminando las rebabas o los bordes afilados que quedan en el metal.

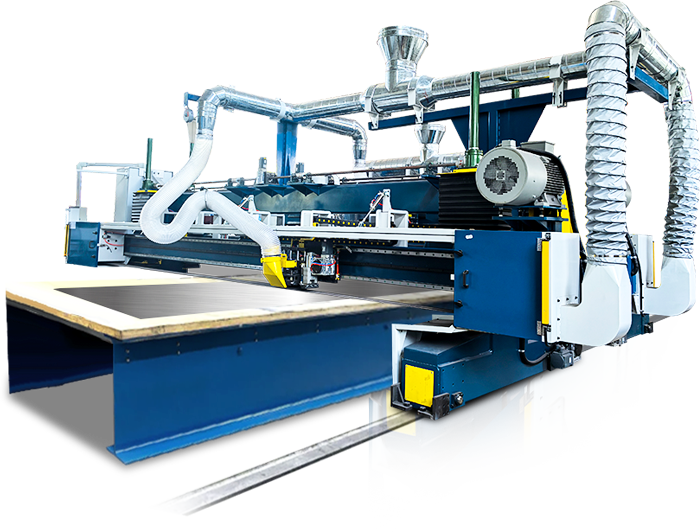

Máquina niveladora

- Nuestra serie procesa eficazmente diversas chapas medianas, gruesas y laminadas en caliente, incluyendo acero al carbono, acero inoxidable y acero de aleación. Diseñadas para chapas grandes y pesadas, nuestras máquinas enderezadoras cuentan con una construcción excepcionalmente duradera y resistente para garantizar una planitud uniforme para cada chapa y placa.

- Como líderes del mercado mundial en tecnología de nivelación, ADV ofrece una amplia gama de aplanadoras de rodillos de alto rendimiento. Reconocidas por su precisión, nuestras máquinas ofrecen constantemente resultados excepcionales. Al utilizar nuestra tecnología de enderezado de vanguardia, puede reducir significativamente los desechos y el tiempo de reprocesamiento, añadiendo un valor significativo a su proceso de producción.

Máquina pulidora

- Desbarbadora y pulidora de chapa metálica de Maquinaria ADV . La máquina se utiliza principalmente para el pulido de acero inoxidable, chapa de aluminio, chapa y superficie plana, etc ... Póngase en contacto con nosotros

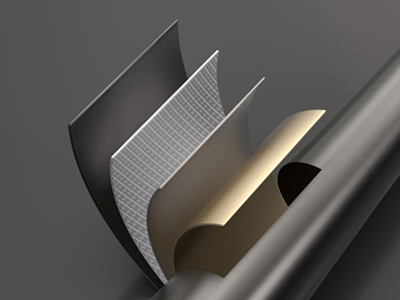

- El pulido es el proceso de refinar aún más la superficie metálica después del esmerilado, eliminando los finos arañazos y defectos superficiales de la superficie metálica después del esmerilado, con la acción de un cepillo no tejido y líquido abrasivo, la superficie metálica pulida es reflectante y tiene un brillo notable, mejorando así su aspecto.

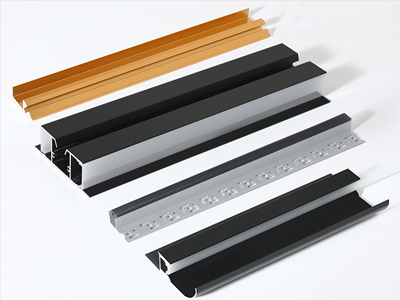

- Utilizando bandas abrasivas o muelas con diferentes rejillas, se puede reducir la rugosidad de la superficie del tubo. Al mismo tiempo, se pueden equipar diferentes muelas de pulido para conseguir acabados de espejo, cepillado y otros acabados superficiales.

- Nuestra empresa fabrica principalmente máquinas de desbarbado y pulido de tubos redondos y cuadrados y abrasivos de pulido, todos los productos son especiales para el pulido de metales. Tenemos un equipo de desarrollo de investigación profesional, nuestra filosofía empresarial es trabajar duro para satisfacer las necesidades de los clientes, innovar y desarrollar continuamente, proporcionando calidad de primera clase y servicios integrales a nuestros clientes.

Procesado de metales

Personalizado

Servicios metálicos

LA MEJOR CALIDAD, ADV MAKING

Cobertura completa del proceso, desde el desbarbado hasta el pulido, para el OEM personalizado de productos metálicos de múltiples materiales y formas.

Descubrimos y nos damos cuenta de la belleza del propio metal.

- Proceso de coloreado

Reconstrucción cromatográfica

Proceso exclusivo de coloración

La cobertura a todo color de Pantone, combinada con la tecnología de recubrimiento PVD a nanoescala, consigue una personalización ultraprecisa del color de la superficie metálica con Δ E ≤ 0,5, cumpliendo simultáneamente los requisitos de doble proceso de los dispositivos médicos antihuella dactilar y el color degradado de la electrónica de consumo.

- Tecnología de texturas

Reconstrucción de texturas

Ingeniería topológica de superficies

- 12 tipos de procesos de textura de precisión cubren un nivel de precisión de 0,01 mm, proporcionando una personalización completa de la escena, desde antideslizante médico hasta microestructura óptica;

- La tecnología de acoplamiento de cinco ejes consigue un control de tolerancia de 0,02 mm para superficies 3D, desarrollando de forma sincronizada superficies funcionales y decorativas.

¿Por qué necesitamos

Desbarbar

¿Piezas metálicas?

A través de más de 20 años de persistencia y trabajo duro en la tecnología de rectificado de superficies metálicas y equipos de desbarbado automático, ADV ha hecho de la alta calidad, la larga vida útil y la seguridad nuestro único indicador.

La importancia del metal Desbarbado y pulido

Durante los procesos de mecanizado de metales, como el corte, el fresado, el taladrado y el estampado, se generan rebabas y bordes afilados.

La eliminación de estas rebabas puede mejorar el estado de la superficie de las piezas y garantizar que los procesos posteriores, como el montaje, la pulverización o la soldadura, puedan llevarse a cabo con eficacia.

Desbarbadoras En ADV Machinery

Maquinaria ADV entiende el futuro de la fabricación de chapas y el tratamiento de metales.

El diseño modular aporta más posibilidades para el desbarbado y pulido de chapa y el acabado, en el que las estaciones trabajan juntas e independientemente.

A través de más de 20 años de persistencia y trabajo duro en la tecnología de rectificado de superficies metálicas y equipos de desbarbado automático, ADV ha hecho de la alta calidad, la larga vida útil y la seguridad nuestro único indicador.

Testimonios de clientes

Estamos orgullosos de haber ayudado a miles de clientes de varios países consiguió el desbarbado de metales y pulido de servicios prestados buenos productos.

Steve Ro****

Maquinas de calidad,para el elogio de todos y grandes gerentes, todo esta a un alto nivel y siempre son amables

Adam W****

Esta máquina es una bestia. Me encanta. Viene con todos los accesorios. Un trabajo impresionante. Gracias de nuevo a ADV Grinding Tools Co., Ltd.

Marcos Fe****

Estoy encantado de haber recibido las desbarbadoras. La calidad de la fabricación proporcionada por el equipo de ingenieros y de producción es excelente. La representante del servicio de atención al cliente (Melody) ha sido excelente, amable, rápida en responder y muy servicial a la hora de resolver cualquier duda o problema.

Velgherstel A***

He comprado la desbarbadora ADV 508-RW800. Es una máquina muy buena a un precio muy asequible. Además, la máquina es muy bonita y tiene un diseño muy atractivo.

Póngase en contacto hoy mismo sus necesidades de productos.

Últimas noticias

Aquí podrá profundizar en el conocimiento de la Rectificación Avanzada.

- Noticias, Tecnología

- Noticias, Tecnología

- Exposición

Las preguntas sobre

desbarbadora y pulidora de metales

Desde el taller hasta el escenario mundial, mantenemos un enfoque implacable en nuestro principio fundacional: Hacer que "Engineered by Maquinaria ADV"sinónimo de liderazgo técnico y fiabilidad operativa. A medida que las industrias evolucionan, estamos preparados para capacitar a los fabricantes con Soluciones de acabado de metales que no sólo cumplen las especificaciones, sino que redefinen las posibilidades.

¿Está interesado en una de nuestras máquinas pero quiere verla antes en acción? Entonces programe una demostración sin compromiso en nuestra sala de exposiciones. Si no es posible visitar nuestra sala de exposición, también puede enviarnos sus propios productos para una demostración a distancia. Póngase en contacto con nosotros para obtener más información sobre el desbarbado y pulido de metales, y nos pondremos en contacto con usted para hablar de fechas y opciones.

¿Tiene necesidades diferentes? Estaremos encantados de ayudarle con una solución personalizada. Por favor, Contacto!

¿Por qué ADV es tan fuerte en el sector?

Se estableció en 2002, posee más de 1000 metros cuadrados de investigación y espacio de oficinas, más de 40000 metros cuadrados de fábrica. Todas las máquinas, pasó la autenticación CE de la Unión Europea.

¿Pueden desbarbarse, redondearse los bordes y acabarse las superficies con una sola máquina o proceso?

Sí, desbarbado, redondeo de bordesy acabado superficial puede hacerlo todo una sola máquina, la 508 RWR. Esta máquina de 3 etapas es de una sola cara y puede procesar incluso piezas de chapa tan pequeñas como 30 mm x 30 mm (imán o adsorción al vacío). Las 3 etapas se componen de una cinta de esmerilado para el desbarbado, cepillos giratorios para el redondeo de bordes y una cinta de vellón para el acabado de la superficie.Se trata de una desbarbadora profesional, tanto si tiene piezas de trabajo finas como gruesas.

¿Qué materiales son adecuados para el desbarbado y el redondeo de bordes con la desbarbadora?

En ADV Desbarbadora puede procesar una amplia gama de aleaciones metálicas. Estas aleaciones incluyen acero, aluminio, latón, cobre, titanio, acero inoxidable e incluso aleaciones especiales.

¿Por qué cantear chapa redonda con cepillos rotativos?

Gracias a los cepillos giratorios de la Desbarbadora ADVEl redondeo uniforme de cantos para chapas metálicas puede conseguirse en una sola pasada. Estos cepillos giratorios pueden lograr un resultado de redondeo de bordes de hasta 2 mm en todos los bordes para una amplia variedad de aleaciones metálicas.

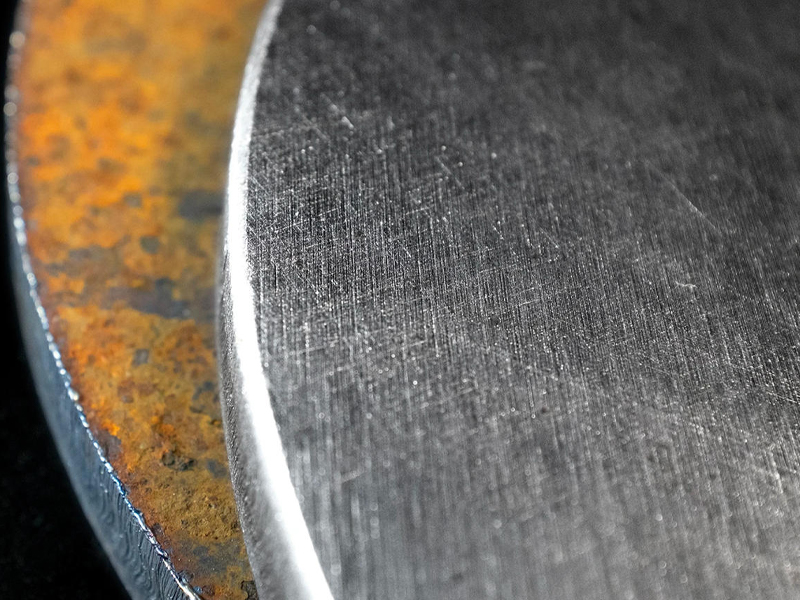

¿Por qué es importante eliminar el óxido láser de las piezas metálicas?

El óxido láser se crea a lo largo del borde de corte cuando se corta con un láser alimentado por oxígeno. Este óxido láser a lo largo del lateral de las piezas impedirá que se adhiera cualquier revestimiento de pintura y dificultará la soldadura. Por lo tanto, la eliminación del óxido láser a lo largo de los bordes de corte mejorará en gran medida los procesos posteriores como la pintura y la soldadura.