![]() 24h customer hotline +86 15395181370

24h customer hotline +86 15395181370

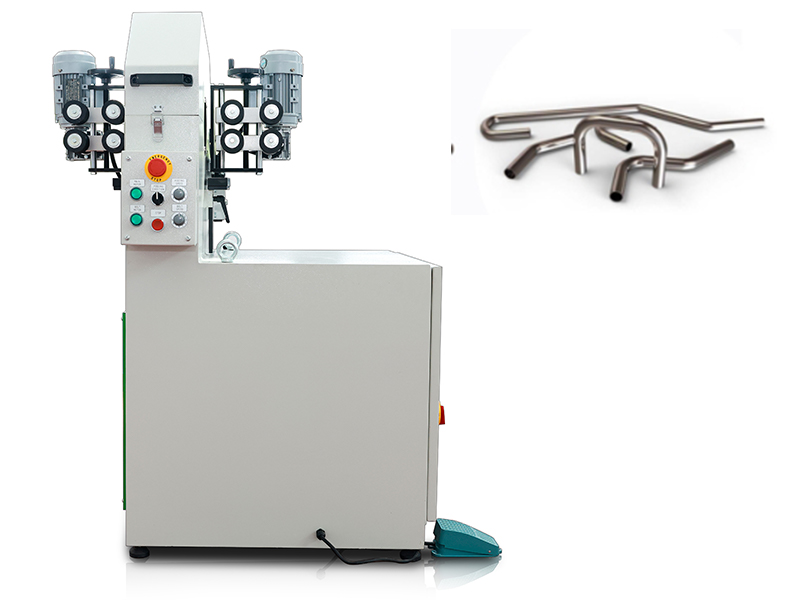

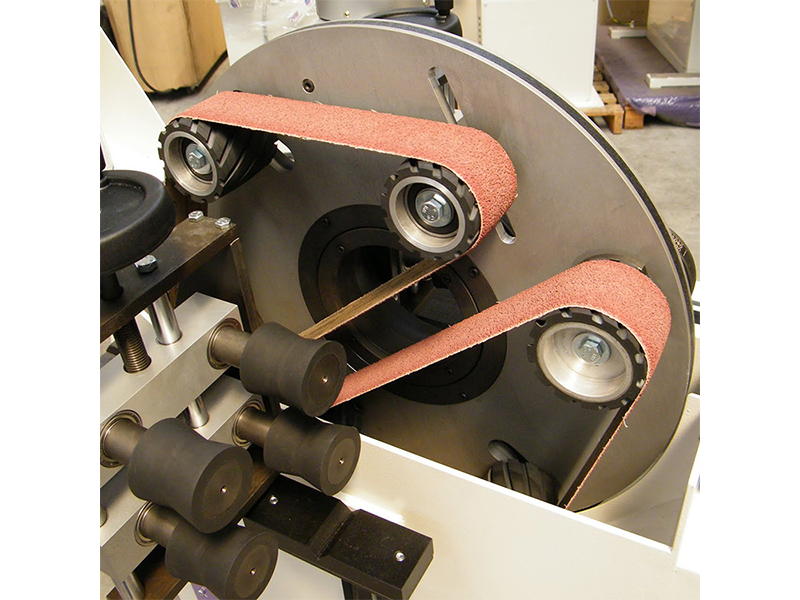

ADV® 108-1 Tube Pipe Polisher

Product Details

Tube Polisher – Stainless steel elbows pipe polishing or Straight Tube Polishing

1 station

- Ideal for polishing curved round tubes with a tight radius and diameters up to 110mm.

- The 108-1 round tube finishing machine is the ideal equipment to polish small diameter round tubes with a tight bend radius.

- Polishing water taps and faucets, finishing handles, or polishing in curved tubular products are easily achieved with the 108-1.

- The ADV planetary system allows the work to be done without rotating the tube, delivering the best results on both bent and curved tubes.

The planetary tube polisher machine with an automatic feeder and a photoelectric abrasive belt opening, which can grind straight tubes, curved tubes, round tubes, oval tubes and other irregular sections.

Item:

- Available tube diameter: 10-110mm

- Total motor power: 3.94kW

- Abrasive Belt Motor power: 2.2kW

- Speed of abrasive belt: 7.8-18 m/s

- Transfer wheel motor power: 1.5 kW

- Feeding system motor power: 2 x 0.18 kW

- Speed of feeding: 0.7-4 m/min

- Size of tube polisher abrasive belts: (2)940 x 50 mm

See for yourself: the Video of the ADV® 108-1 Pipe Polishing machine for straight tube!

See for yourself: the Video of the ADV® 108-1 Pipe Polishing machine for curved tube!

Tube Polisher:

ADV® 108 Pipe Finishing Machine

In the world of stainless steel tube finishing, the constant pursuit of superior quality, productivity, and versatility is key. For those working with tubes of varying geometries — whether round, oval, elliptical, straight, or curved — choosing the right technology can make all the difference in the final result and process efficiency.

Which industries need tube finishing & polishing?

Industries such as food, pharmaceutical, chemical, medical, and aerospace demand high-quality finishes to:

✔ Prevent contamination and corrosion: Smooth surfaces reduce the adhesion of residues and microorganisms.

✔ Ensure regulatory compliance

✔ Improve durability and resistance: Uniform finishes increase resistance to wear and fatigue.

✔ Optimize subsequent processes: Facilitate welding, assembly, and inspection.

More Products

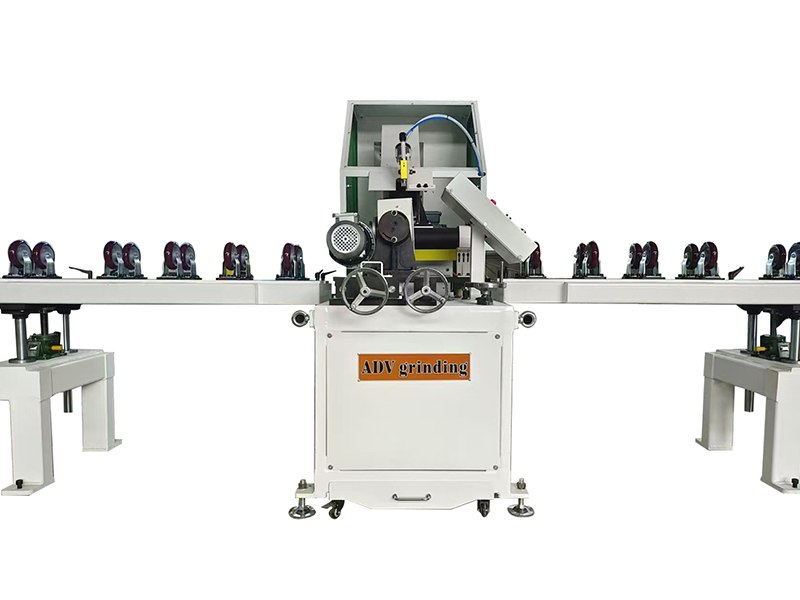

106 tube pipe polishing machine can be equipped with 1-10 sets of grinding heads by different requirements, is equipped with the planetary system and enables a faster finishing job than single–station machines.

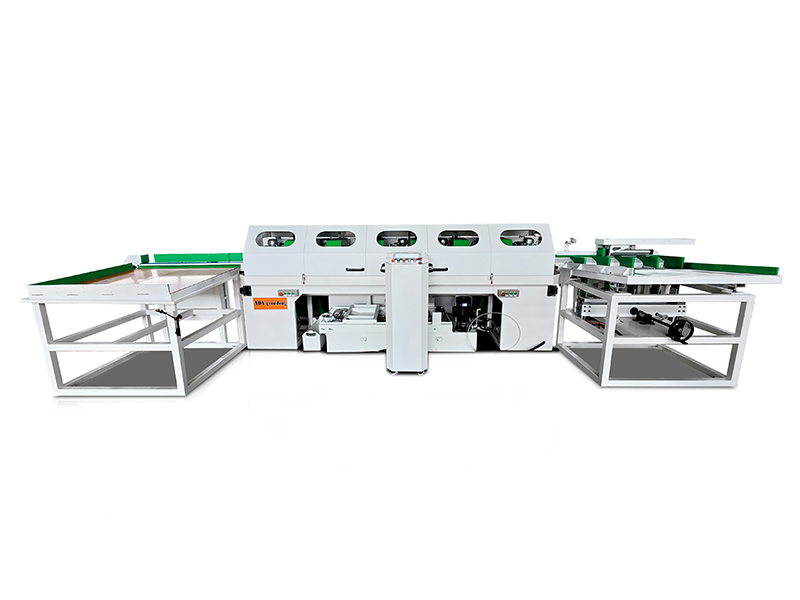

The 108-6 multi-station planetary tube polishing machine is a device used for polishing the surface of straight tubes.

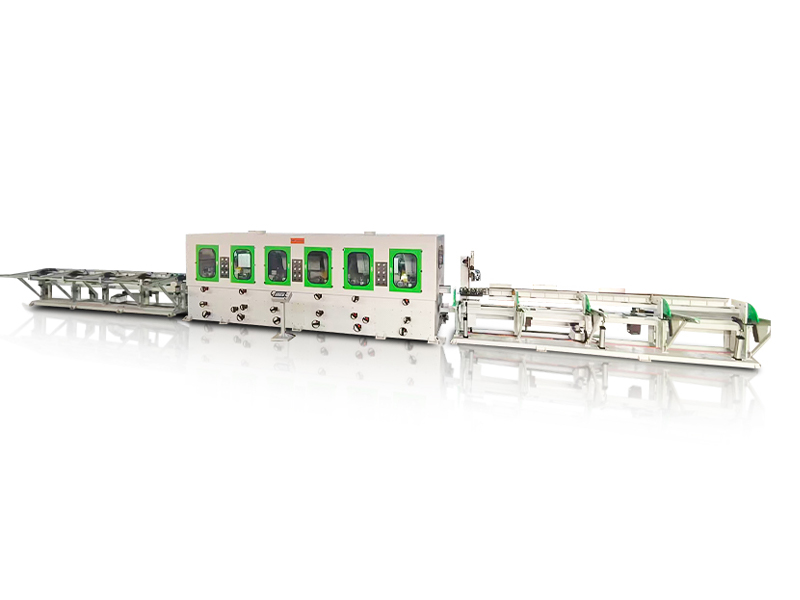

106-N - By using abrasive belts or grinding wheels with different grids, the surface roughness of the pipe can be reduced. At the same time, different polishing wheels can be equipped to achieve mirror, brushed and other surface finishes.