![]() 24h customer hotline +86 15395181370

24h customer hotline +86 15395181370

ADV® 508-HRW

Product Details

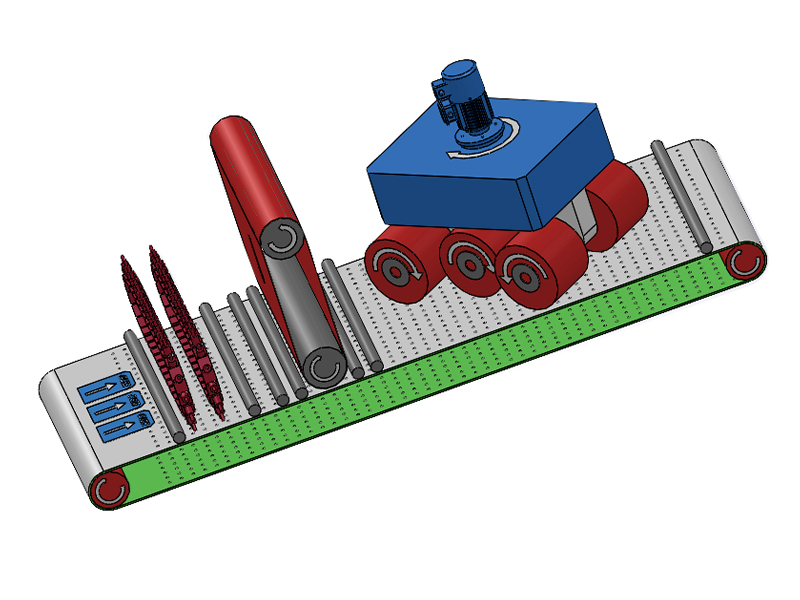

HRW Deburring Machine – Hammerhead & Wide sanding belt & Rotary brush

Slag removal from carbon steel plates usually refers to the removal of welding slag or cutting slag produced during welding or cutting. These slags can adhere to the surface of the steel plate, affecting the aesthetics and surface quality. The HRW series deburring machine can remove surfaces slag and perfect rounding on metal in one time.

- Heavy slag, also known as dross, is basically molten metal on parts that are produced during thermal cutting operations: oxy-fuel, flame cutting and plasma cutting.

- The ADV 508-HRW series is used for heavy slag removal, deburring,edge rounding and oxide layer removal of thick carbon steel plate.

- The standard available width is 800mm,1000mm, 1300mm, 1600mm, or customized.

- The deburring machine can process parts with a minimum size of 30mm*30mm(with a vacuum or magnetic table).

Effective processing width:

300/630/800/1000/1300/1600mm(11.8″/24.8″/31.5″/39.4″/51.2″/63″)Effective processing thickness:

0.5-100mm(0.02-3.9″)conveying speed:

0.5-7m/minMinimum workpiece size:

5050 mm(Vacuum)3030 mm(Magnetic)

Hammer set service life:

6-12 monthsslag removal height:

5mm(0.2”)

- Deslagging is a labour-intensive, dirty job which still often involves the use of a hammer and chisel. Or an electrically powered hand-held machine is used. Because of the heavy workload for both the operator and the hand machine, these hand machines have to be replaced regularly. This causes high costs, an extra waste flow and possible health problems (e.g. HAVS) for the operator.

- The 508 HRW and 508 HR were developed by ADV to automatically remove slag generated during plasma or oxy-fuel cutting. These compact machines can be easily integrated into any production line. They remove the slag before the product reaches the deburring machine for edge rounding, optimizing the production process and enhancing workplace safety.

- The removed slag material is collected in a bin and can be disposed of as scrap. By performing slag removal separately, contamination in the deburring machine is prevented.

- The machines are equipped with an easy-to-use touchscreen control and are ergonomically designed. They remove slag from sheet metal parts up to 600 mm wide using two robust slag breaker rollers that strike the product twice per revolution. The product is then ready for further finishing in the deburring machine.

The video of the 508 HRW Deburring Machine :

More Products

Heavy slag removal machine for plasma, flame cutting parts,Deslagging,Deburring. removing slag before the product reaches the deburring machine for edge rounding.