![]() Linha direta do cliente 24 horas por dia +86 15395181370

Linha direta do cliente 24 horas por dia +86 15395181370

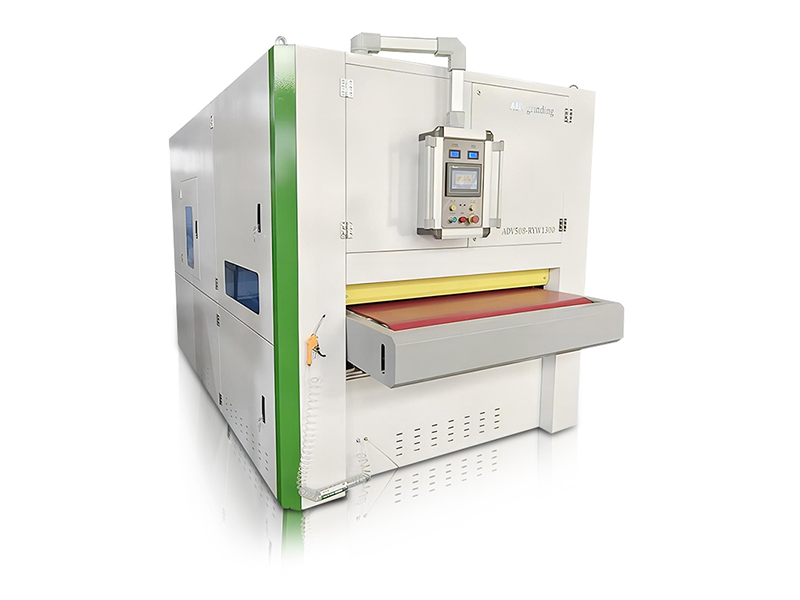

ADV® 508-RW

Detalhes do produto

2 Stations : Rotary Brush and Grinding Belt. The 508 RW with dry sanding belt plus universal roller brush combination model. It is mainly used to deal with deburring, chamfering function, workpiece edge, hole deburring treatment. Deburring Machine can be configured in different combinations according to your final surface requirements for the product.

- Drum Deburring Machines : Drum deburring machines use rotating drums to perform abrasive deburring, ideal for batch processing of metal parts.

- Minimum workpiece size :Magnetic suction 30*30 mm, Vacuum suction 50*50 mm

The Station of the 508 RW Máquina de rebarbar:

- The 508 RW deburring machine with 2 station .

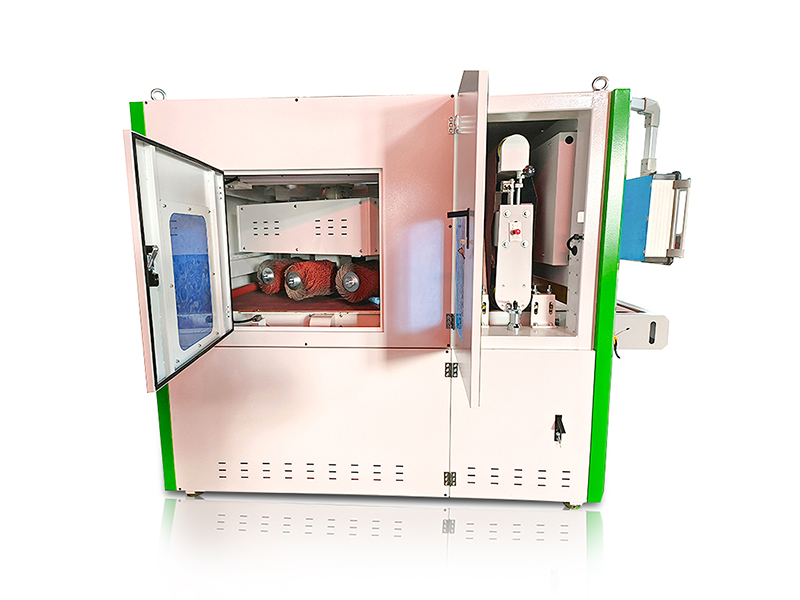

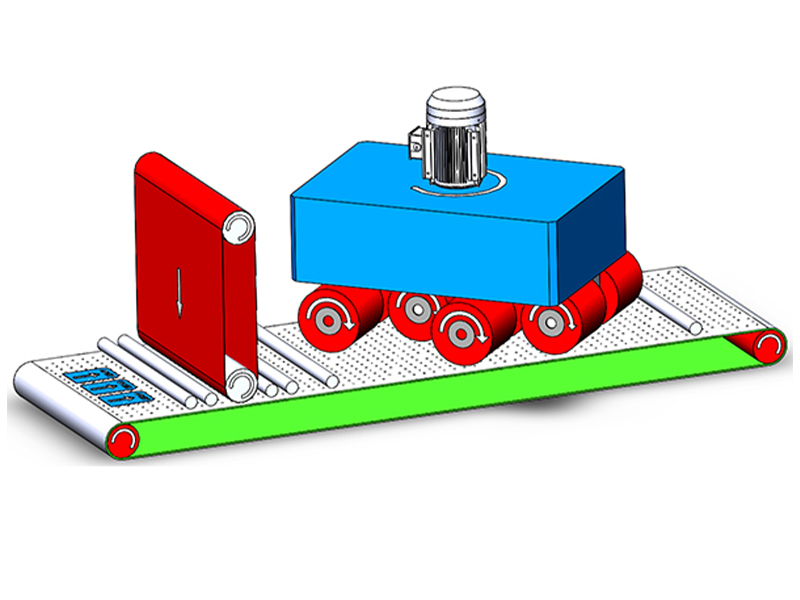

- Sanding belt removes slag, oxidized skin, large flanging and other burrs on the surface of the workpiece.

- Edge rounding with rotary brushes Rotary brushes offer the most effective and consistent edge rounding results, They make contact with the sheet metal parts from all directions.

| Largura disponível | 300/450/630/800/1000/1300/1500/1600 mm |

|---|---|

| Available thickness | 0,5-100 mm |

| Velocidade de alimentação | 0,5-8 m/min |

| Rotation speed of rotary brush | 9-21 r/s |

| Rotary brush size | 300*300 / 300*400 mm |

| Edge rounding range | R 0,1-1,0 mm |

| Worktable | 900 – 980 mm |

| Minimum processing size | 30*30 mm (magnético)

50*50 mm (vácuo) |

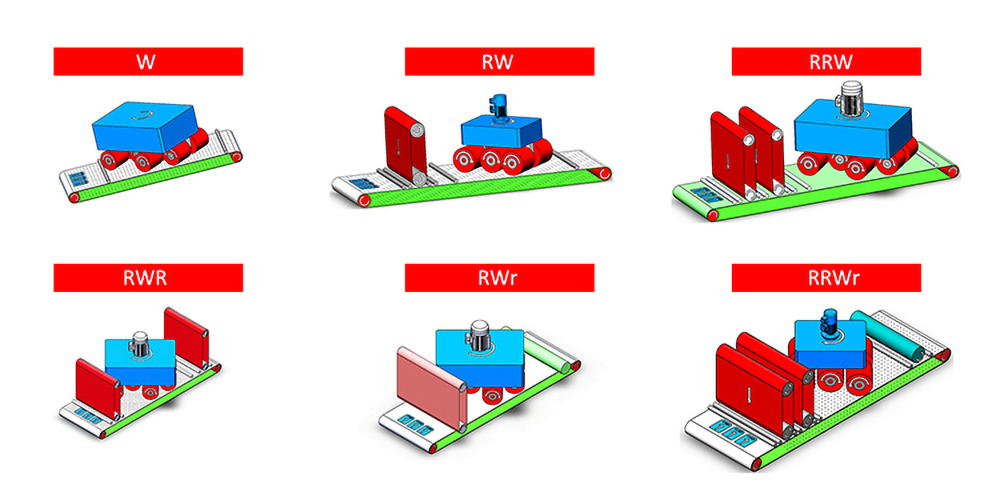

Available model:

Finished – Deburring and Edge Rounding (Chamfering)

508RW Perguntas frequentes

How to realize burr treatment on the surface of workpiece?

RW with 1 set of wide belt mechanism, the belt rotates at high speed to remove slag particles, oxidized skin, large flanges and other burrs on the surface of the workpiece.

How to realize workpiece edge and hole deburring treatment?

1. RW with 2/3 rows (2/3 groups per row) of universal roller brush structure, roller brush abrasive high-speed rotation, the surface of the workpiece to beat, so that the surface of the workpiece around the edge of the contour of the hole and smooth rounded, resulting in rounded corners.

2. For stamping, shearing, laser machine cutting, plasma cutting and other processes generated in the burr can be all-round one-time removal, so that all the edges of the workpiece, holes to achieve a small R arc effect, the processing process is safe, reliable, so that the workpiece to achieve the perfect effect.

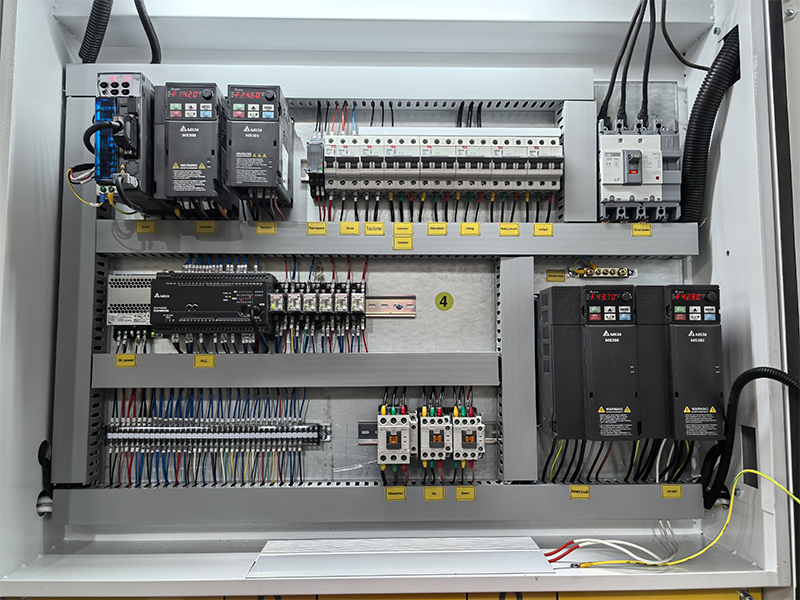

Why configure wet/dry dust collector?

Wet /dry dust removing method: the dust generated by the host in the work through the dust collection port effectively suck away most of the dust. Eliminate the potential danger of dust explosion and keep the inside of the equipment clean.

Porque é que é importante remover o óxido a laser das peças metálicas?

O óxido laser é criado ao longo da aresta de corte quando se corta com um laser alimentado a oxigénio. Este óxido laser ao longo do lado das peças impedirá a aderência de qualquer revestimento de tinta e tornará a soldadura muito mais difícil. Por conseguinte, a remoção do óxido laser ao longo das arestas de corte melhorará consideravelmente os processos a jusante, como a pintura e a soldadura.

Porquê biselar chapas metálicas redondas com escovas rotativas?

Thanks to the rotary brushes of the ADV® 508RW, uniform edge rounding for sheet metal can be achieved in a single pass. These rotary brushes can achieve an edge rounding result of up to R(0.1-1.0) all edges for a wide variety of metal alloys.

Mais produtos

Máquinas de rebarbação automatizadas para peças cortadas a laser, plasma, oxicorte e puncionadas. Rebarbação, arredondamento de arestas, deslaginação e acabamento das suas peças metálicas com elevada qualidade e eficiência

Rebarbação e polimento automáticos - remove escória, pele oxidada, grandes rebarbas e outras rebarbas. Fio comprido reto para fins decorativos e chapa de aço inoxidável.

máquinas multifunções automatizadas de polimento e rebarbação, para que possa otimizar o seu processo de produção e melhorar a qualidade dos seus resultados. elevada flexibilidade, fiabilidade consistente do processo e elevada qualidade das peças