![]() 24h customer hotline +86 15395181370

24h customer hotline +86 15395181370

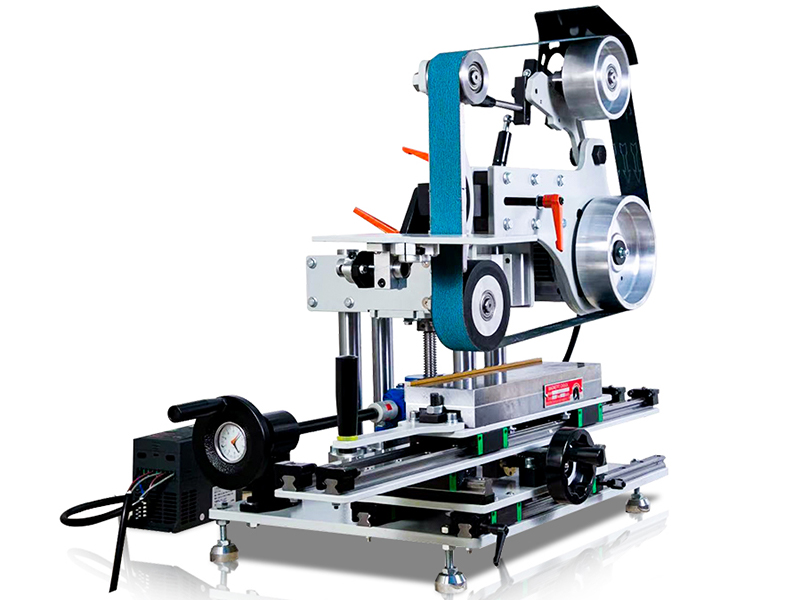

ADV® G32 Roller Metal Leveling

Product Details

Plate & Sheet Metal Roller Levelers:

- Roller diameter : 32mm

- material thicknesses from 0.4 mm to 2.4 mm (0.015″ to 0.1″)

- Touch screen human-machine interface, parameter setting, automatic adjustment

- The previous option on the touch screen can save parameters, and you can directly call it up when you use it.

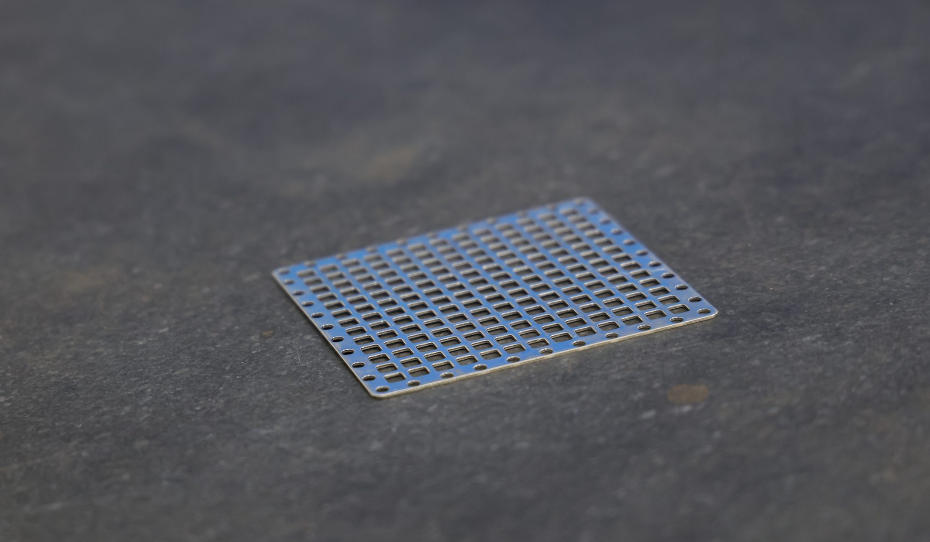

Part Leveling Machines for Thin Sheet Metal Parts and Blanks :

Conservatively estimated that 400-long material can pass through once, about 1700 pieces, and pass through twice, about 850 pieces (per hour)

G32 series Machine Parameters :

| No | Model | ADV G32-300 | ADV G32-500 | ADV G32-800 | ADV G32-1300 |

| 1 | Roller diameter | 32mm | |||

| 2 | Roller number | 19(upper 9/lower 10) | |||

| 3 | Nominal leveled width | 300mm | 500mm | 800mm | 1300mm |

| 4 | Rated plate thickness | 0.4-1.2mm | 0.4-1.2mm | 0.4-1.2mm | 0.4-1.2mm |

| 5 | Max. plate thickness | 2.4mm | |||

| 6 | Leveled precision | H/K | |||

| 7 | Applicable | Tape coiling, strip steel, sheet metal, etc | |||

- ADV® G32 CNC metal roller levelers is specially designed for various metal materials. It can accurately process workpieces of different thicknesses and sizes, automatically eliminate internal stress, restore the flatness of workpieces, ensure dimensional accuracy and assembly quality, improve product appearance quality while enhancing functional performance, meet strict precision requirements, and is a key link in improving product performance and optimizing product quality.

- The ADV® G32 metal leveling & flattening machine is distinguished by delivering outstanding results, easy operation and a maintenance friendly design.

- Consistently good leveling results for delicate sheet metal parts are important for optimal further processing with accurate results and no rework. The precision leveling machines in our ADV® G32 series ensure flat and nearly stress-free sheet metal parts and entire sheets within seconds. Even delicate sheet metal parts from 0.4 up to 2.4 mm thick are no problem for our ADV® G32 precision leveling machines. The ADV® G32 is extremely easy to maintain and absolutely reliable. With flat and nearly stress-free parts, reworking and rejects in subsequent processes are reduced.

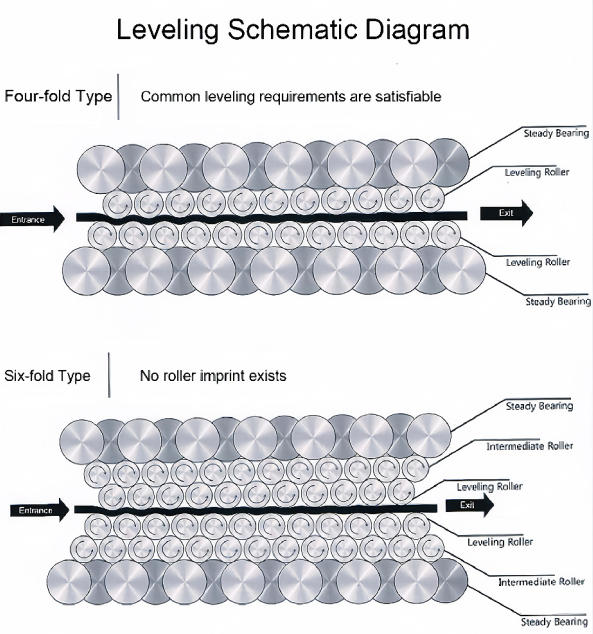

Difference Between Four-High and Six-High Leveling Machines:

Number of Rolls and Structure:

- Four-High Leveling Machine:Composed of two upper and two lower rolls, featuring a simpler structure. It is suitable for processing thinner plates or materials with lower stress requirements.

- Six-High Leveling Machine:Equipped with three upper and three lower rolls. The additional supporting rolls evenly distribute pressure, allowing it to handle thicker and harder plates with higher leveling precision.

Leveling Capability:

- Four-High Leveling Machine:Designed for light and thin materials such as aluminum alloys and stainless steel sheets, mainly for materials with lower yield strength.

- Six-High Leveling Machine:Suitable for thicker or higher-yield-strength materials such as high-strength steel plates and cold-rolled steel. It offers greater leveling capability and versatility.

Pressure Distribution:

- Four-High Leveling Machine:Fewer rolls result in concentrated pressure points, which may cause indentations or incomplete leveling when processing thick plates.

- Six-High Leveling Machine:The supporting rolls distribute pressure evenly, reducing surface damage and improving leveling quality.

Plate & Sheet Metal Roller Levelers FAQ

What is the difference between 2-High、4-High、6-High?

2-High: Coarse leveling Suitable for needs that only require visual leveling.

4-High: Standard machine Meets the needs of most factories.

6-High: Suitable for demanding precision plates Sensitive materials are less prone to indentation Stronger leveling capability.

Is the operation of CNC metal roller levelers complicated?

Our CNC leveling machines feature a user-friendly interface and simple programming system. Ordinary operators can usually operate them after only a short training period. Although it is highly automated, the actual operation is not complicated. For production lines that require high precision, operators can enter preset processing parameters into the system, and the machine will automatically run according to these settings.

What types of materials can CNC metal roller levelers process?

CNC leveling machines are highly adaptable and can process carbon steel, stainless steel, aluminum alloy, special alloys and composite materials with a maximum thickness of up to 30mm. Especially in mass production or complex material processing, CNC leveling machines are a more efficient and stable choice.

Why do CNC metal levelers provide greater precision and consistency?

CNC leveling machines use computer numerical control systems to accurately control the position and pressure of the leveling head, ensuring that each workpiece can be leveled according to the predetermined procedures and parameters. Automation and digital control greatly reduce the errors caused by human operation, so higher accuracy and consistency can be achieved. Manual leveling machines rely on the experience and judgment of the operator, which is prone to errors, especially in long-term operation or high-precision requirements, and the accuracy will decrease.

More Products

High-performance belt grinder with sturdy machine base.Abrasive belt grinder recommended for: Smoothing over burrs on metal, chamfering edges for welding, and finishing castings, among other uses

Hand pushed sand belt machine(belt sander for metal plate) is suitable for grinding large workpiece welds, surfaces, long belt finishing machine.

116-9 belt grinder's rotating wheel is made of pure aluminum, with good precision and balance.

The machine is designed for dish end manhole external and internal grinding and polishing. It has VFD control, PLC control, and CNC control according to your different requirements on productivities. The available standard diameter for the tank is 300mm-3000mm or customized. The dish head elliptical polishing machine is widely used in medical area,chemical,environmental purification,food,cookware, beverage and water filter,etc.