![]() Línea directa de atención al cliente 24 horas +86 15395181370

Línea directa de atención al cliente 24 horas +86 15395181370

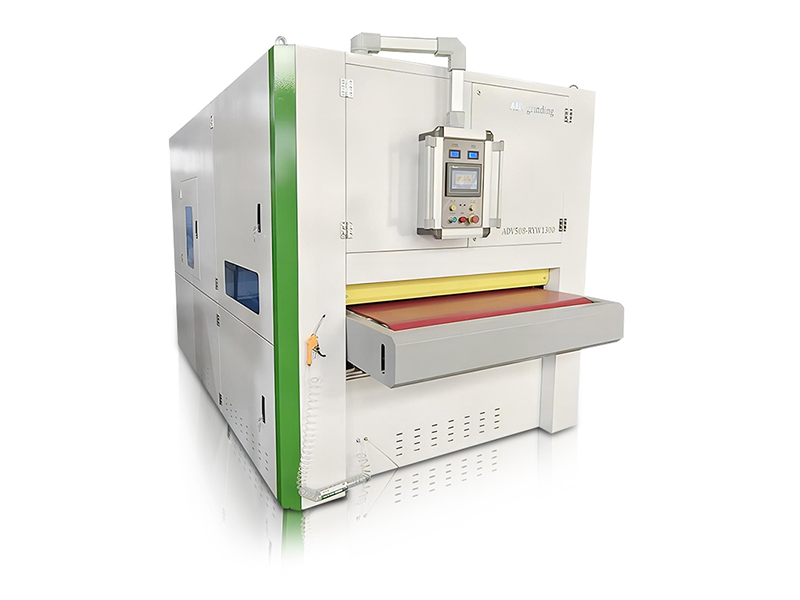

ADV® 508-RW

Detalles del producto

2 Stations : Rotary Brush and Grinding Belt. The 508 RW with dry sanding belt plus universal roller brush combination model. It is mainly used to deal with deburring, chamfering function, workpiece edge, hole deburring treatment. Deburring Machine can be configured in different combinations according to your final surface requirements for the product.

- Drum Deburring Machines : Drum deburring machines use rotating drums to perform abrasive deburring, ideal for batch processing of metal parts.

- Minimum workpiece size :Magnetic suction 30*30 mm, Vacuum suction 50*50 mm

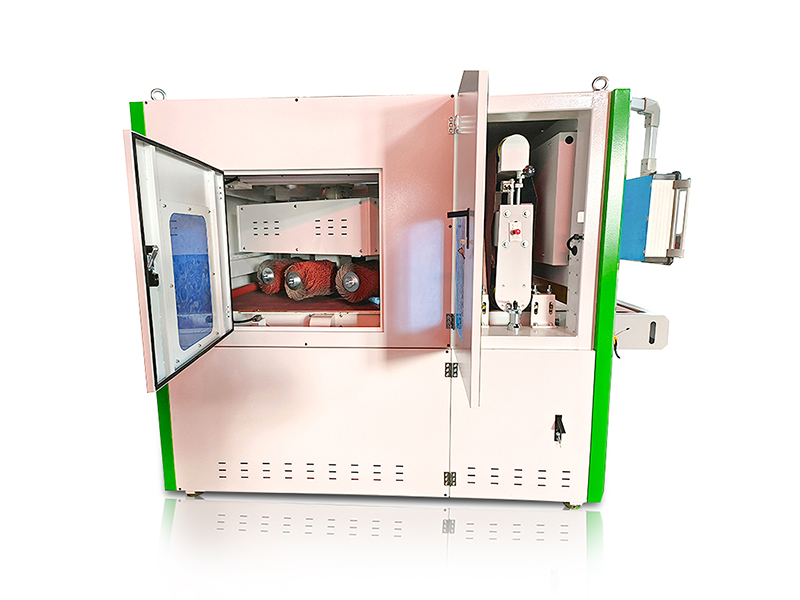

The Station of the 508 RW Desbarbadora:

- The 508 RW deburring machine with 2 station .

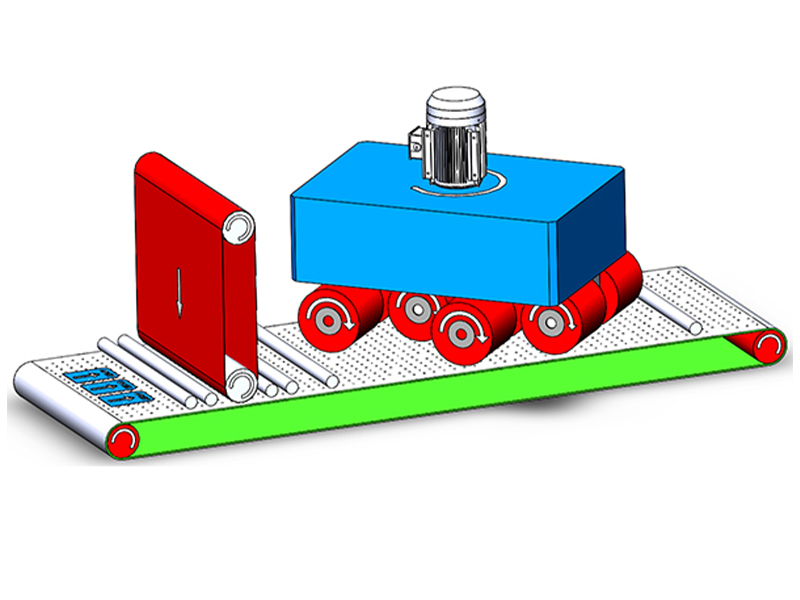

- Sanding belt removes slag, oxidized skin, large flanging and other burrs on the surface of the workpiece.

- Edge rounding with rotary brushes Rotary brushes offer the most effective and consistent edge rounding results, They make contact with the sheet metal parts from all directions.

| Anchura disponible | 300/450/630/800/1000/1300/1500/1600 mm |

|---|---|

| Available thickness | 0,5-100 mm |

| Velocidad de alimentación | 0,5-8 m/min |

| Rotation speed of rotary brush | 9-21 r/s |

| Rotary brush size | 300*300 / 300*400 mm |

| Edge rounding range | R 0,1-1,0 mm |

| Worktable | 900 – 980 mm |

| Minimum processing size | 30*30 mm (magnético)

50*50 mm (Vacío) |

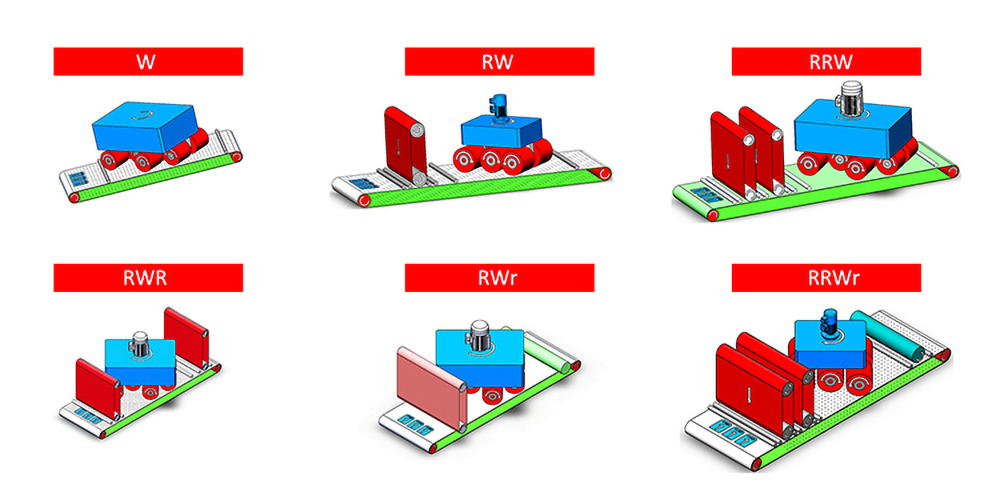

Available model:

Finished – Deburring and Edge Rounding (Chamfering)

508RW Preguntas frecuentes

How to realize burr treatment on the surface of workpiece?

RW with 1 set of wide belt mechanism, the belt rotates at high speed to remove slag particles, oxidized skin, large flanges and other burrs on the surface of the workpiece.

How to realize workpiece edge and hole deburring treatment?

1. RW with 2/3 rows (2/3 groups per row) of universal roller brush structure, roller brush abrasive high-speed rotation, the surface of the workpiece to beat, so that the surface of the workpiece around the edge of the contour of the hole and smooth rounded, resulting in rounded corners.

2. For stamping, shearing, laser machine cutting, plasma cutting and other processes generated in the burr can be all-round one-time removal, so that all the edges of the workpiece, holes to achieve a small R arc effect, the processing process is safe, reliable, so that the workpiece to achieve the perfect effect.

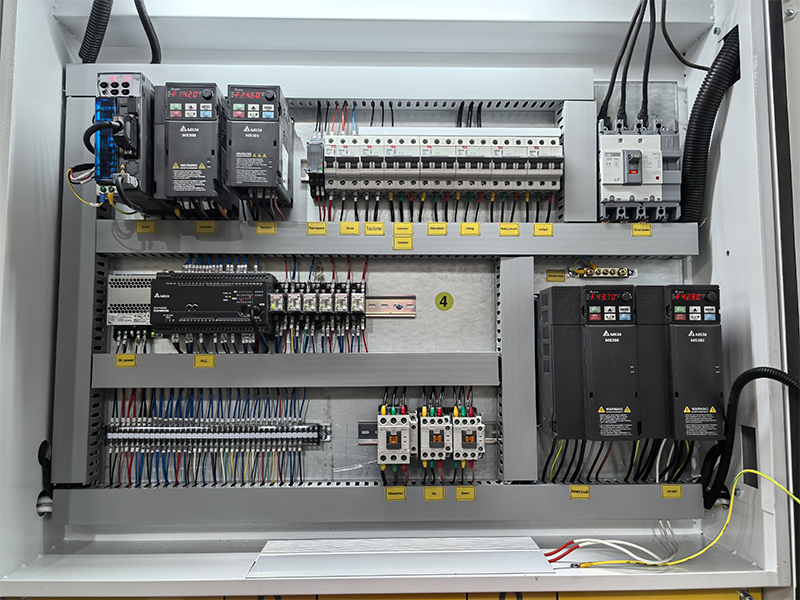

Why configure wet/dry dust collector?

Wet /dry dust removing method: the dust generated by the host in the work through the dust collection port effectively suck away most of the dust. Eliminate the potential danger of dust explosion and keep the inside of the equipment clean.

¿Por qué es importante eliminar el óxido láser de las piezas metálicas?

El óxido láser se crea a lo largo del borde de corte cuando se corta con un láser alimentado por oxígeno. Este óxido láser a lo largo del lateral de las piezas impedirá que se adhiera cualquier revestimiento de pintura y dificultará la soldadura. Por lo tanto, la eliminación del óxido láser a lo largo de los bordes de corte mejorará en gran medida los procesos posteriores como la pintura y la soldadura.

¿Por qué cantear chapa redonda con cepillos rotativos?

Thanks to the rotary brushes of the ADV® 508RW, uniform edge rounding for sheet metal can be achieved in a single pass. These rotary brushes can achieve an edge rounding result of up to R(0.1-1.0) all edges for a wide variety of metal alloys.

Más productos

Desbarbadoras automáticas para piezas cortadas por láser, plasma, oxicorte y punzonadas. Desbarbe, redondee bordes, desbarbe y acabe sus piezas metálicas con gran calidad y eficacia.

Desbarbado y pulido automáticos - elimina escoria, piel oxidada, grandes rebabas y otras rebabas.Alambre recto largo para fines decorativos y chapa de acero inoxidable .

máquinas automáticas multifunción de desbarbado y pulido, para que pueda agilizar su proceso de producción y mejorar la calidad de las piezas. gran flexibilidad, fiabilidad constante del proceso y alta calidad de las piezas