![]() 24h customer hotline +86 15395181370

24h customer hotline +86 15395181370

Product Details

The Video Of The 508 RYW Series

- In the first station Sanding Belt(R station) of the deburring machine,burrs and imperfections are removed with a grinding belt, resulting in a flat, burr-free surface.

- After grinding, four oscillating disc brushes(Y station) follow that exert light pressure on the product, ensuring a rounding on both inner and outer contours.

- As a final operation, the Multibrush – Rotary Brush(W station), wich ensures your product is perfectly finished. The six brushes provide a non-directional finish and round the edges with a radius of 2+ mm, giving the product a high-quality and durable appearance.

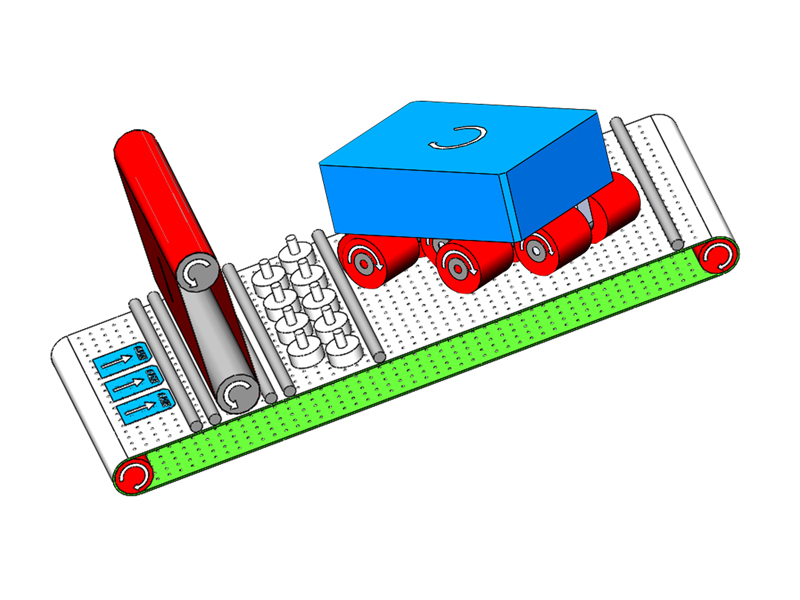

Deburring Machine – Wide Belt & Disc Brush & Rotary Brush

- ADV 508 RYW Multibrush finish machine. The entire finish machine can be operated via the touchscreen, which is very intuitive and ensures effortless control. With the touchscreen, it is easy to select different deburring/polishing/finish programs, leading to high reproducibility of product quality and preventing operator setting errors.

- In the first station of the deburring machine, burrs and imperfections are removed by a grinding unit, resulting in a flat, burr-free surface. After grinding, four oscillating disc brushes apply light pressure to the product, ensuring a rounding on both inner and outer contours. The final operation involves the Multibrush, wich ensures your product is perfectly finished & super edge rounding.

- The two brushes provide a non-directional finish and round the edges with a radius of 2+ mm, giving the product a high-quality and durable appearance.

Deburring Machine Basic Prameters

Available width:

630/800/1000/1300/1600 mm

Available thickness:

0.5-100 mm

Feeding speed:

0.5-8 m/min

Rated voltage:

AC 380V/50Hz or customized

Abrasive belt speed:

5-15 m/s

Edge rounding range:

R 0.1-1.0 mm

Worktable:

900 – 980 mm

Minimum processing size:

30*30 mm (Magnetic)

50*50 mm (Vacuum)

Frequently Asked Questions-Chamfer

What types of Y station(disc brushes) are there?

1. Wire wheel: removes stains and rust from metal surfaces.

2. Nylon wheel: for finer cleaning and grinding.

3. Emery cloth wheel: for surface grinding and deburring.

4. Carbon brush wheel: removes dirt from electrical equipment.

5. Wire drawing wheel: removes oxide layers, scratches or irregular surfaces to create a fine grinding effect

How to realize workpiece deburring treatment?

The abrasive grinding belt station can operate independently.The independent operation of the abrasive belt station can achieve effects such as wire drawing, polishing, descaling, and slag deburring on the surface of metal sheets.

More Products

508 M300 Manual deburring is necessary for specialized products or low-volume runs. Manufacturers can skip over the sometimes lengthy programming process of an automated machine. It’s also a better way to ensure a smooth finish on a part that’s too fragile for semi automatic equipment.

3 blet grinidng machine to deburr after laser cutting.The purpose of finishing is to enhance the quality and visual appeal of the metal sheet parts while also contributing to their protection. It ensures a uniform finish and can assist in improving the adhesion of coatings, paint, or other materials on the surface.

2 blet grinidng machine to deburr after laser cutting.With ADV’s advanced finishing machines, you can apply various finishes to your metal sheet parts. By using the right abrasive belts in combination with the appropriate speed, finish your metal sheet parts to your preferences, such as with a linear finish or a non-directional finish.

Rr Metal finishing machine for brushing and polishing.Finishing of metal sheet parts refers to the process of rounding and refining the surfaces of sheet parts to give them a smooth, aesthetically appealing appearance. removing imperfections, burrs, rough edges, and other undesirable features from the surface.