![]() 24h customer hotline +86 15395181370

24h customer hotline +86 15395181370

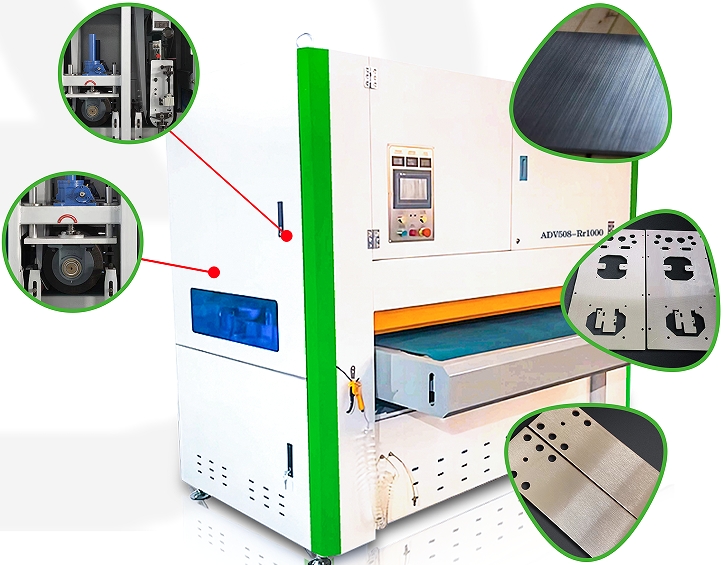

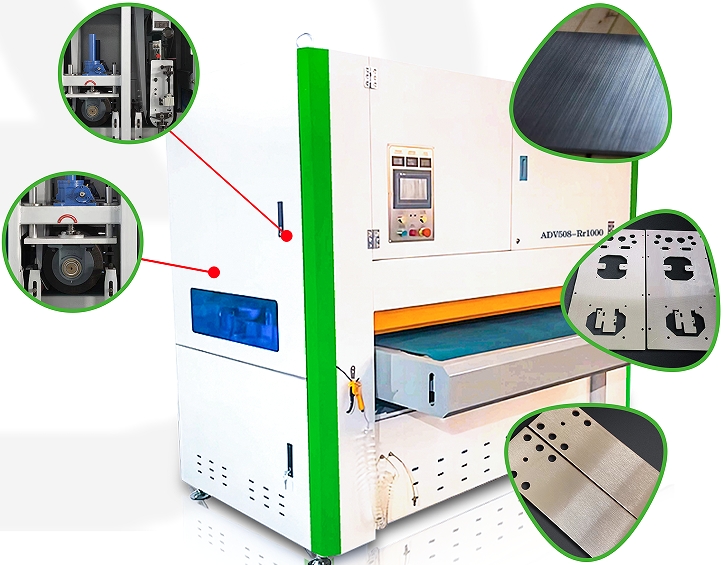

ADV® 508-Rr

Product Details

Finishing metal surface – 508 Rr Deburring Machine(Dry or Wet) – Wide belt & Roller Brush

The ADV® Rr(wet or dry) This equipment is through the type processing equipment, through one/two/three groups of sand belt and a group of drawing wheel mechanism to remove the slag particles on the surface of the workpiece and the surface of the product drawing polishing, through the processing, will not destroy the dimensional precision of the workpiece. Sand belt station can realize wire drawing, polishing, peeling and welding slag of metal surface.

The ADV® Rr(wet or dry) Primarily designed for comprehensive surface treatment, this equipment performs metal finishing, laser oxide layer removal, polishing, and other processes. It effectively removes burrs, weld spots, and imperfections from operations like punching, shearing, and laser cutting in a single pass. This ensures safe, reliable processing, achieving a high-quality finish for workpieces.

- Wide belt: Suitable for surface grinding, polishing, de-scratching, removing longitudinal burrs, descaling, roughing and etc. of all kinds of flat board parts.

- Non-woven wheel(Roller Brush): Perfect hairline finish, brushed finish.

- Effective processing width : 300/630/800/1000/1300/1600mm(11.8″/24.8″/31.5″/39.4″/51.2″/63″)

- Effective processing thickness: 0.5-100mm(0.02-3.9”)

- Conveying speed: 0.5-10m/min

- Minimum werkpiece size : 280mm

- Processing : Dry or wet

- Multi-station surace Roughness inspection : ≤0.1um

Facts at a glance

- Abrasive non-woven fleeces are available in various abrasive materials and grits.

- Wide belt units are most frequently used for surface finishing sheet metal.

- Scratches are removed from the surface via the surface finishing fleece.

- The abrasive fleece used influences the removal rate and roughness of the surface.

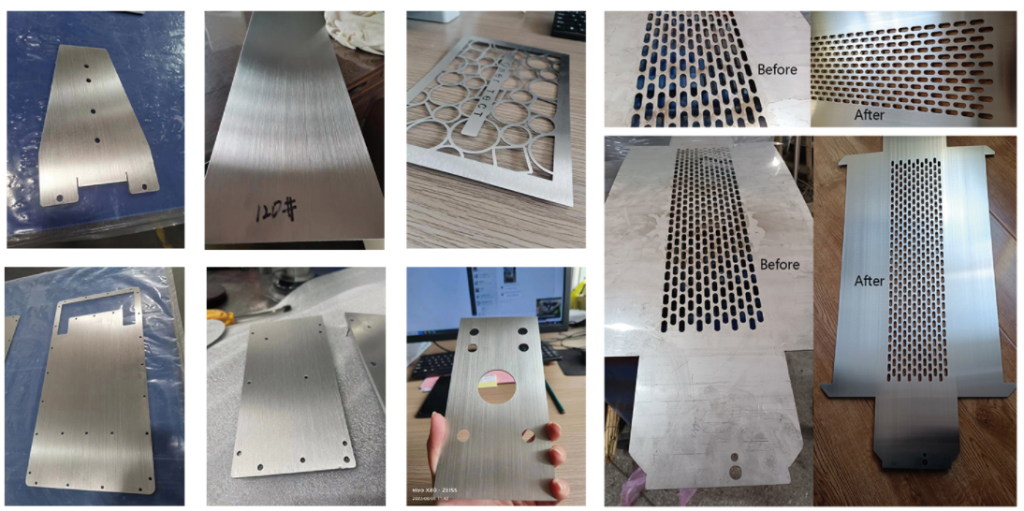

After surface finishing

Frequently Asked Questions

How the 508Rr works?

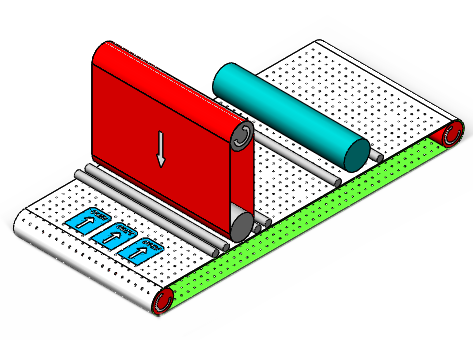

This equipment is a pass-through processing machine featuring one/two wide belt stations and a polishing wheel(roller brush) for removing slag particles and large burrs from workpiece surfaces, along with surface polishing. The pass-through design maintains dimensional accuracy. The wide belt stations handle surface finishing, oxide layer removal, and weld slag deburring on metal sheets. The machine uses a high-temperature-resistant conveyor belt for workpiece transport, with variable frequency speed control for precise handling.

What materials are suitable for 508Rr?

The 508Rr can process a wide array of metal alloys.These alloys include Stainless steel , aluminum , carbon steel , coated workpiece , galvanized plate , copper plate and even specialty alloys.

Surface Finishing Sheet Metal with a Wide Belt :

Wide belt units are probably the most frequently used units for surface finishing. Here, an abrasive belt is guided and driven between two rollers. One roller is only used for deflection while the other presses the belt onto the sheet metal surface. Scratches are removed from the surface of the sheet metal. The desired surface finish can also be achieved at the same time. The abrasive belts utilized are available in different abrasive materials and grits, thus influencing the removal rate and roughness of the surfaces in various degrees.

The final surface result is a combination of the machine, tools, processing settings, and throughput speed.

Surface Finishing Sheet Metal with a Roller Fleece Brush :

The roller fleece brush consists of a core surrounded by abrasive fabric. The roller is set in rotation within the machine and presses against the surface of the sheet metal parts passing underneath. This removes small scratches and applies a polish to the surface. The roller fleece brush produces a very homogeneous pattern. It is advantageous for the tools if the passage position varies in order to maintain even wear and thus ensuring consistent results. The roller fleece brush is available in various composites and grits.

What are the Advantages of Surface Finishing Sheet Metal?

1.Improved paint adhesion

A rough surface is particularly suitable for paint adhesion.

2.Aesthetics

Finely polished sheet metal parts have a particularly attractive appearance.