![]() 24h customer hotline +86 15395181370

24h customer hotline +86 15395181370

ADV® 508 M300

Product Details

Manual deburring machine and edge rounding of sheet metal parts from small to large.

DEBURRING | EDGR ROUNDING | Surface Finishing

- 508 M300 Manual deburring is necessary for specialized products or low-volume runs. Manufacturers can skip over the sometimes lengthy programming process of an automated machine. It’s also a better way to ensure a smooth finish on a part that’s too fragile for automatic equipment.

- The new 508 M300 manual deburring machine offers adjustable grinding head speed for precise control, easy arm height and angle adjustments for versatile operation, and a quick-change grinding head system for tool-free head replacement. Combined with a lightweight servo motor and durable aluminum alloy arm, it ensures faster, more efficient deburring with minimal maintenance, making it the perfect solution for high-quality surface finishing.

- This budget machine is built ergonomically, robustly executed and especially safe because of the two-button control. A mobile deburring machine is standard equipped with freely adjustable speed. Workpieces are fixated on the rubber mat while you work safely. You can achieve great time savings compared to manual deburring and better, continuous finishing results.

Applicable metarial :

Stainless steel , aluminum , carbon steel , coated workpiece , galvanized plate , copper plate

The Video of the ADV® M300 deburring machine !

- The balance arm allows you to adjust the grinding pressure to your liking, by means of the spring package, from floating to more pressure. The motor is equipped with two grinding heads, enabling you to switch quickly between grinding tools. You can mount all standard tools with an M14 fastening, to disc brushes delivered by ADV for the various processes. The dimensions of the work surface are 1200 x 750 mm (W x D). However, there is no maximum lenght to workpieces because you can fold down the side panels easily. The front panel you can flip also making it possible to work on wider products as well. This is the machine for deburring and edge rounding safely at a budget price.

- Mechanical polishing arm : 1200mm,360(47.2”,360°)

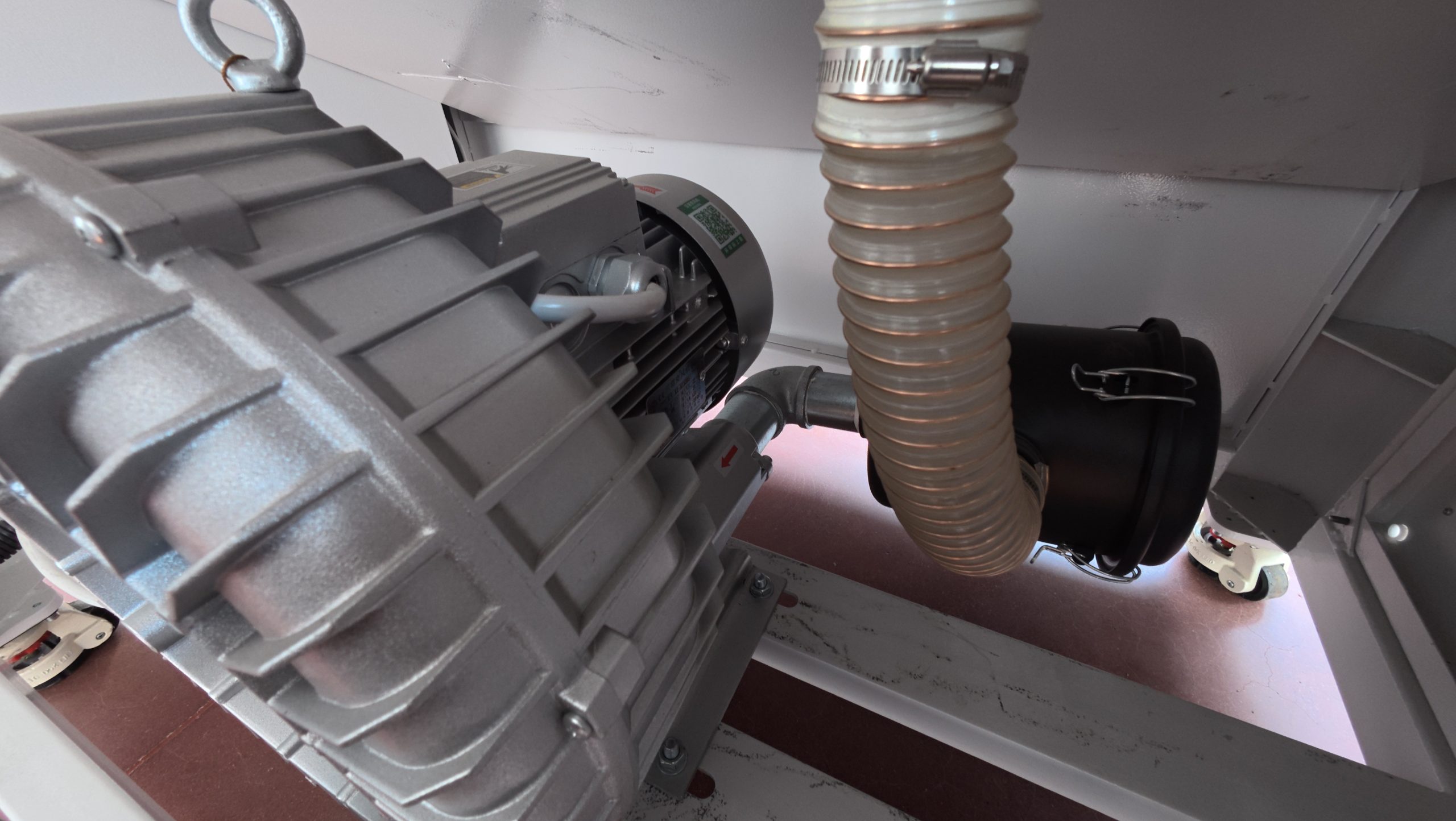

- Grinding head motor power : 1.1kw/2.2kw

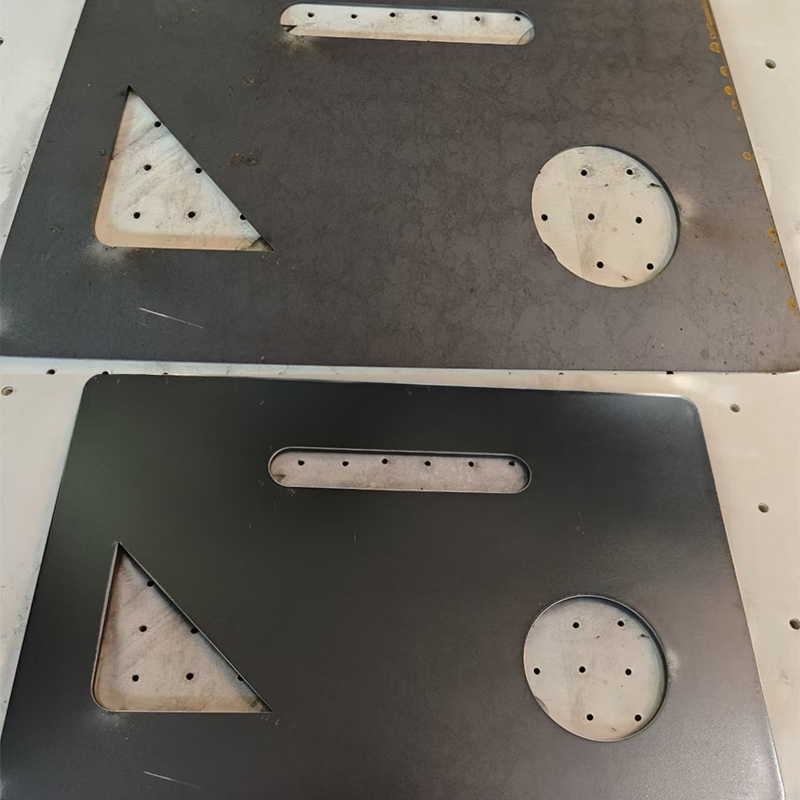

- Vacuum working area : 300300mm (11.811.8”)

- Disk brush head : 2

- Vacuum adsorption : 3kw

- Minimum workpiece size : 5050 mm (Vacuum) 3030 mm(Magnetic)

ADV®508 M300 FAQ

Why choice manual deburring machine?

The Manual Grinder is designed for flawless deburring, edge rounding, and metal finishing. Its portable head features two mounting handles, allowing you to install two different types of grinding brushes. One side can be fitted with an abrasive medium for heavy-duty grinding, while the other can hold a brush for deburring, edge rounding, or finishing. A mirror finish can also be achieved when needed. Additionally, the 180-degree rotating shaft allows for quick and easy switching between consumables, enhancing workflow efficiency.

508M300 product Advantages

1. Portable design with dual mounting handles for easy handling.

2. Compatible with a wide range of abrasive materials for customized grinding.

3. Capable of creating a mirror finish on metal surfaces.

4. 180° rotating shaft for quick switching between consumables.

5. Ideal for deburring, edge rounding, and metal finishing.

6. Whether you’re working with aluminum, steel, or other metals, this manual grinder ensures you achieve the best results every time.

Why process parts larger than the working table?

Although the working table of this manual deburring machine has a limited size, it is still capable of processing parts that are larger than the table. This is due to the swing arm design and unique features of the machine.

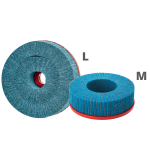

More Options deburring tools for Manual Deburring

Hard for the removal ofhard burrs. Medium for the removal of other (various) burrs.

Deburring and edge rounding of various metals.

Deburring and strong edge rounding of stainless steel with bigger radius.

Primary and secondary burrs + strong edge roundings.

Pregrinding, light deburring and finish grinding.

Pregrinding, primary burr removal.