![]() 24 saat müşteri yardım hattı +86 15395181370

24 saat müşteri yardım hattı +86 15395181370

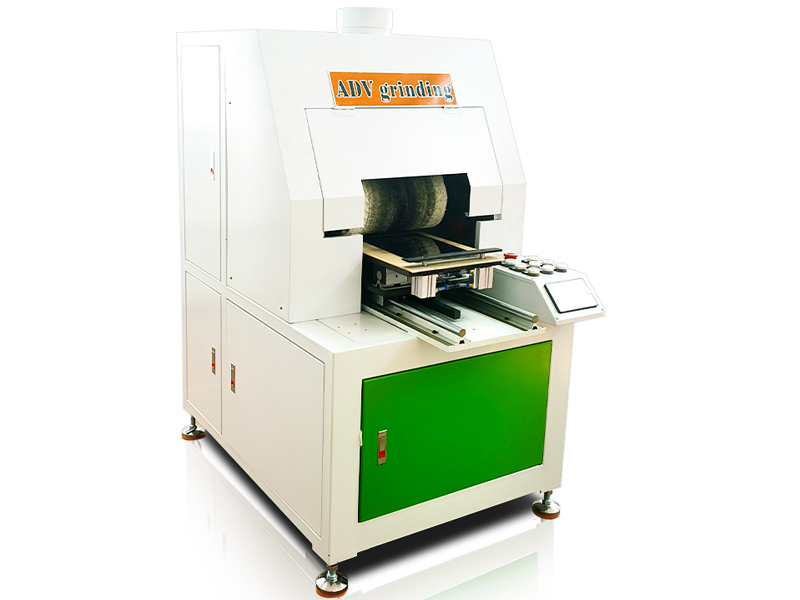

Parlatma Makinesi

ADV®'den Sac Metal Parlatma Makinesi. Makine esas olarak paslanmaz çelik, alüminyum levha, levha ve düz yüzey vb. parlatmak için kullanılır.

Bugün bize ulaşın!

Metal parlatma makineleri atölye ve fabrikalarda metal yüzeyleri pürüzlü veya donuk durumlardan parlak, rafine yüzeylere dönüştürmek için tasarlanmış temel ekipmanlardır. Ürün yelpazesi çok geniştir ve farklı gereksinimleri karşılar:

Zorlu Ortamlar İçin: Ağır hizmet tipi metal parlatma makineleri ve endüstriyel metal parlatma makineleri, fabrikalarda ve büyük ölçekli üretimde sürekli çalışma için üretilmiştir. Bu sağlam sistemler, genellikle güçlü motorlar, dayanıklı yapı ve yüksek hacimli çıktı için özellikler içeren önemli iş yüklerinin üstesinden gelir. Endüstriyel cilalama ve parlatma makineleri, özellikle sıralı cilalama aşamaları yoluyla ayna benzeri yüzeyler elde etmeye odaklanır.

Ölçek ve Uygulama: Tüm üretim hatlarını otomatikleştiren devasa endüstriyel metal parlatma makinelerinden kompakt tezgah üstü metal parlatma makinelerine ve küçük metal parlatma maki̇neleri̇ Atölyeler, prototipleme için ideal, her alan ve görev için bir makine var. El tipi metal parlatma makineleri (en iyi el tipi metal parlatma makinesi seçenekleri dahil) karmaşık işler, kavisli yüzeyler veya nokta parlatma için maksimum esneklik sunar. Tutarlı, yüksek verimli sonuçlar için otomatik metal parlatma makineleri manuel müdahaleyi en aza indirir.

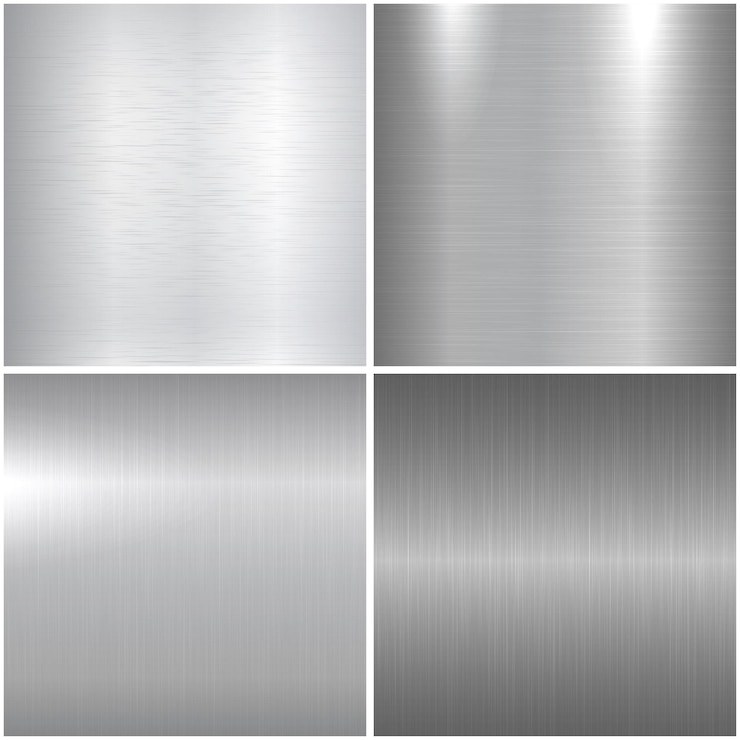

Özel Son İşlem: Özel uygulamalar özel çözümler gerektirir. Sac parlatma makineleri ve metal levha parlatma makineleri büyük, düz paneller için optimize edilirken, metal levha parlatma makineleri daha kalın stokları işler. Metal numune parlatma makineleri, metalürji ve kalite kontrol laboratuvarlarında numuneleri mikroskobik analize hazırlamak için çok önemlidir. Metal yüzey parlatma makineleri tüm bu cihazların genel hedefini kapsar: istenen estetik ve işlevsel yüzey kalitesine ulaşmak.

Temel Bileşenler: Etkili parlatma, doğru metal parlatma araçlarına dayanır. Makinelerde çeşitli metal parlatma makinesi fırça tipleri (sisal, bez, aşındırıcı dolgulu), parlatma diskleri, kayışlar, diskler ve bileşikler kullanılır. Küçük metal parlatma aletleri genellikle ayrıntılı çalışma için el ünitelerini tamamlar.

Doğru Ekipmanı Bulmak: İster belirli bir görev için en iyi metal parlatma makinesini arıyor ister satılık genel metal parlatma makinesi seçeneklerine göz atıyor olun, iş yükü, malzeme türü, istenen yüzey, mevcut alan ve bütçe gibi faktörleri göz önünde bulundurun. Metal taşlama makinesi fiyat boyut, güç, otomasyon seviyesi ve markaya göre önemli ölçüde değişir. Ağır hizmet tipi metal parlatma makinesi endüstriyel modellerinden çok yönlü el tipi metal parlatma makinelerine ve özel metal parlatma makinelerine kadar seçenekler mevcuttur. sac taşlama maki̇neleri̇.

Özünde, güçlü endüstriyel sistemlerden kompakt tezgah üstü veya el tipi ünitelere kadar metal parlatma makineleri, profesyonel kalitede yüzeyler elde etmek, görünümü iyileştirmek, korozyon direncini artırmak ve metal yüzeyleri daha ileri işlemler veya nihai kullanım için hazırlamak için gerekli gücü, hızı ve kontrolü sağlar.

- Düzensiz Desen Parlatma

Bu ürünle cilalı paslanmaz çeliği üst düzey dekoratif panellere dönüştürün 506 Çok Desenli Tekstüre Makinesi. SS200/300/400 serisi saclar (0,5-4 mm kalınlık) için tasarlanan 5 titreşimli kafa tasarımı hassas dokular oluşturur:

- Kaba Rastgele Taneli Kaplama (kaba rastgele)

- İnce Doğrusal Fırçalanmış Kaplama (mikro desen)

- Kumlanmış Rastgele Taneli (kum püskürtme simülasyonu)

- Su Dalgalanma Efektli Kaplama (3D dalga efektleri)

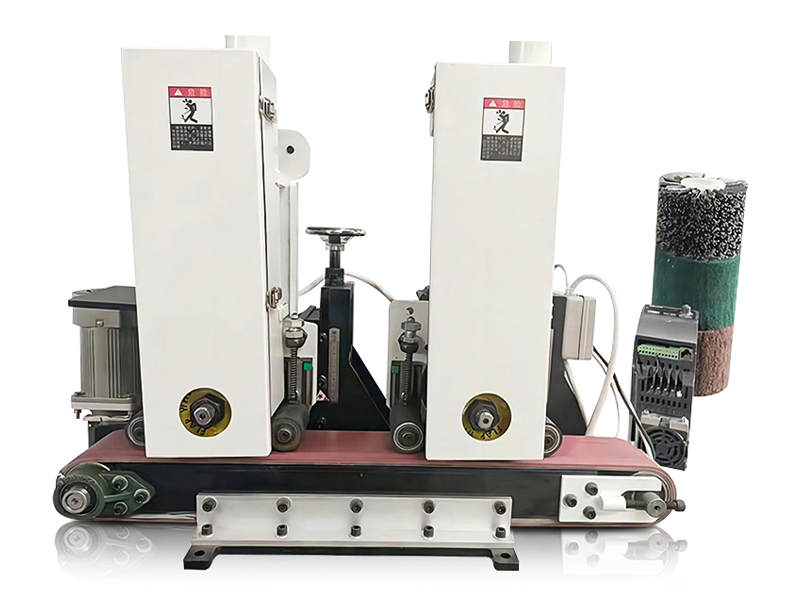

- Düz Metal Parlatma Makinesi

Bu makineler, iş parçalarını zımparalamak veya parlatmak için ileri geri hareket kullanır, bu da onları hem düz hem de konturlu yüzeyler için ideal hale getirir. ADV Makinealüminyum, yumuşak çelik ve paslanmaz çelik parçaların kaynak giderme, taşlama ve parlatma işlemleri için parlatma taşlama makineleri ve bantlı taşlama makineleri bulacaksınız. Parlatma torna tezgahı seçeneklerimizle, ADV Makine metal kaplama parlatma veya bant taşlama ihtiyaçlarınızı karşılamak için ekipman.

- Tekerlek Parlatma Makinesi

Parlaklığı Artırın: Jant Parlatma Makinesi Avantajı

- Estetik Parlatma:

En yaygın uygulama, otomotiv jantlarının görünümünü iyileştirmek için kullanılır. Jant parlatma makineleri yüzey kusurlarını gidererek jantların parlaklığını ve estetiğini artırır. - Oksidasyon Giderme:

Eskidikten veya uzun süre kullanıldıktan sonra otomobil jantlarında oksidasyon katmanları oluşabilir. Jant parlatma makineleri bu oksidasyon katmanlarını gidermek için kullanılır ve jantların daha temiz ve taze görünmesini sağlar. - Korozyon Azaltma:

Parlatma, özellikle sert hava koşullarında jant yüzeyindeki korozyonu azaltmaya yardımcı olur ve böylece jantın ömrünü uzatır.

- Parlatma Makinesi4

Test kopyasını sınıflandırın ve tanımlayın...

- Parlatma Makinesi5

Test kopyasını sınıflandırın ve tanımlayın...

- Parlatma Makinesi6

Test kopyasını sınıflandırın ve tanımlayın...