![]() 24h customer hotline +86 15395181370

24h customer hotline +86 15395181370

商品詳細

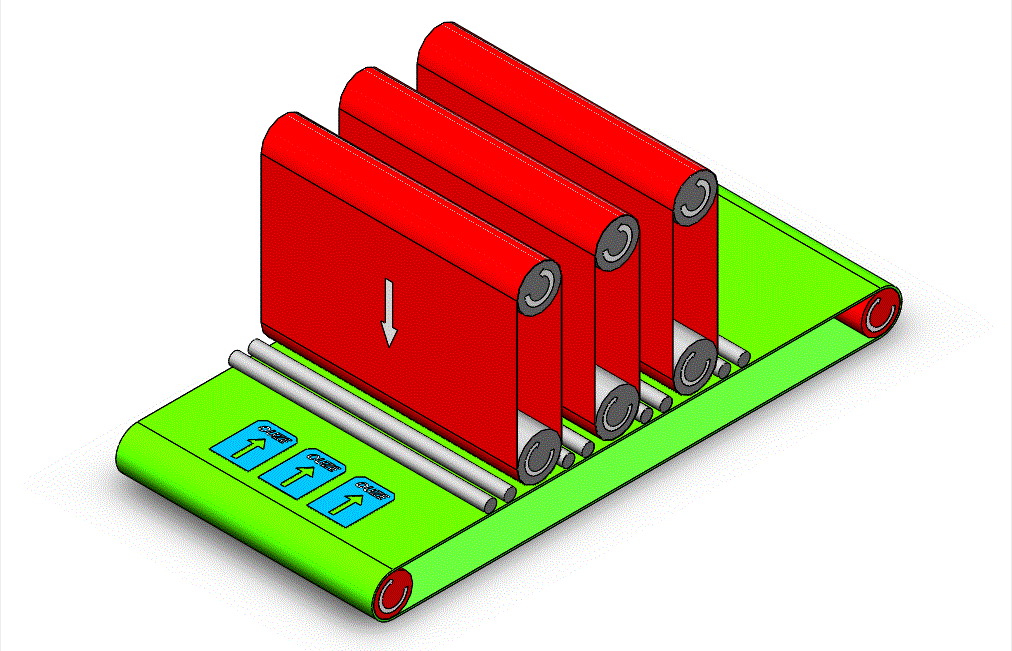

Wet or Dry Deburring and Finishing Machine – Wide Belt & Wide Belt & Wide Belt(3 blet grinidng machine to deburr after laser cutting)

- Effective processing width : 300/630/800/1000/1300/1600mm(11.8″/24.8″/31.5″/39.4″/51.2″/63″)

- Effective processing thickness: 0.5-100mm(0.02-3.9”)

- Conveying speed: 0.5-10m/min

- Minimum werkpiece size : 280mm

- Processing : Dry or wet

- Multi-station surace Roughness inspection : ≤0.1um

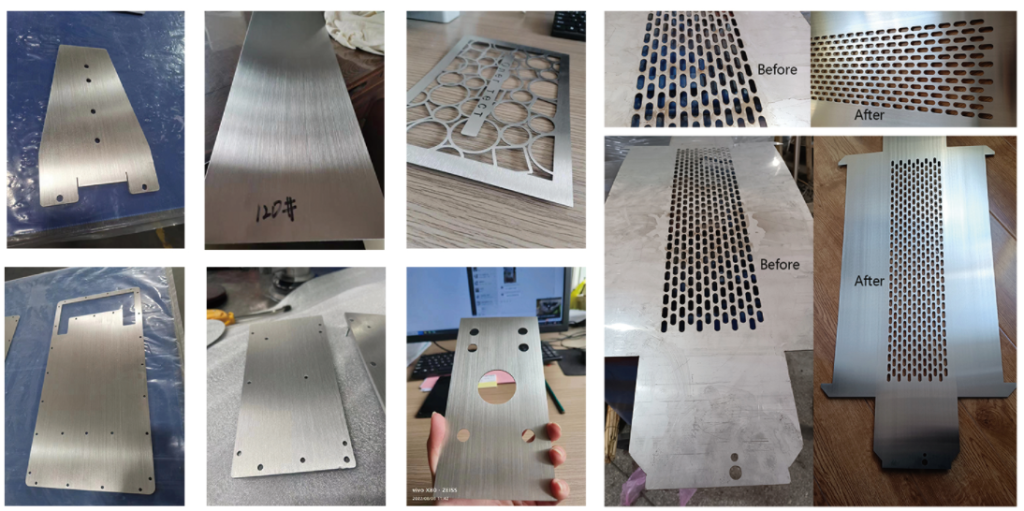

DEBURRING / Oxide Removal / Surface Finish

The ADV 508 RRR wet or dry deburring-Primarily designed for comprehensive surface treatment, this equipment performs metal finishing, laser oxide layer removal, polishing, and other processes. It effectively removes burrs, weld spots, and imperfections from operations like punching, shearing, and laser cutting in a single pass. This ensures safe, reliable processing, achieving a high-quality finish for workpieces.

Stainless steel , aluminum , carbon steel , coated workpiece , galvanized plate , copper plate

Why choose wet deburring?

The whole grinding process is carried out in a wet state, which effectively avoids deformation of the product due to overheating, and the grinding effect is good, safe and efficient.Choosing a wet deburring machine has several advantages, particularly for applications that involve heavy-duty or high-speed processing.

Wet deburring effectively reduces dust and airborne particles, enhancing workplace safety and air quality. The cooling effect of water also prevents overheating, making it suitable for heat-sensitive materials and maintaining consistency in abrasive performance.

Additionally, wet deburring often leaves a cleaner, smoother surface finish, especially for intricate or highly polished workpieces.

その他の製品

2 blet grinidng machine to deburr after laser cutting.ADVの高度な仕上げ機により、金属板部品に様々な仕上げを施すことができます。適切な研磨ベルトを適切な速度と組み合わせて使用することで、直線仕上げや無方向仕上げなど、お好みに合わせて金属板部品を仕上げることができます。

金属シート部品のブラッシングとpolishing.FinishingのためのRr金属仕上げ機は、滑らかで、審美的に魅力的な外観を与えるために、シート部品の表面を丸め、洗練するプロセスを指します。