![]() 24h customer hotline +86 15395181370

24h customer hotline +86 15395181370

商品詳細

The Video Of The 508 RWr Series Deburring Machine

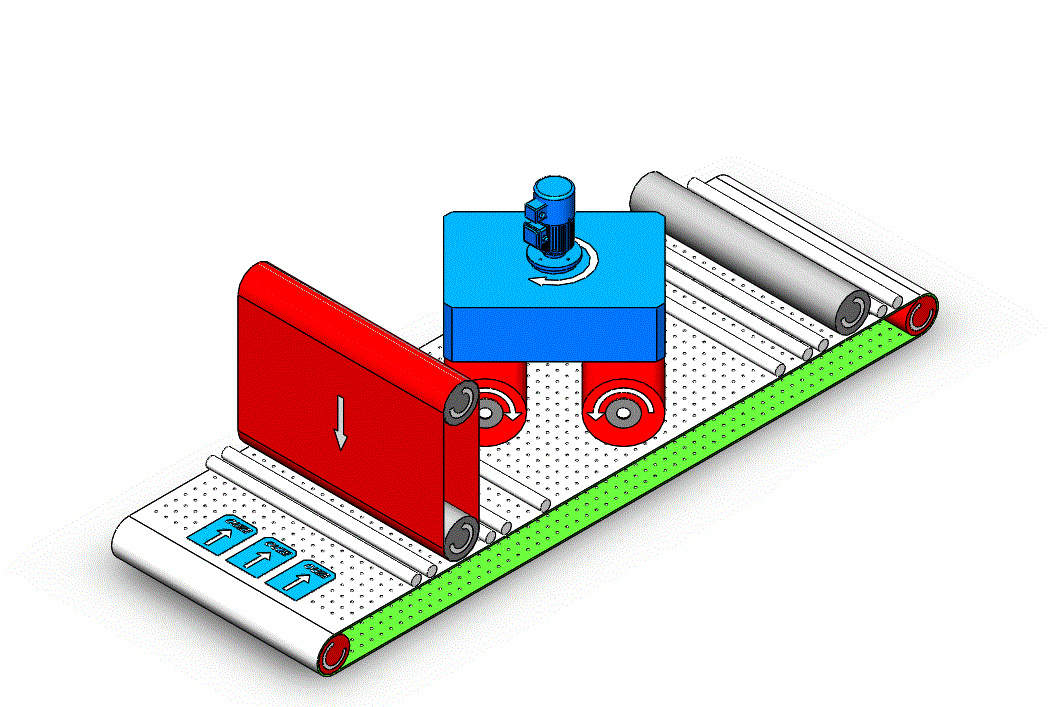

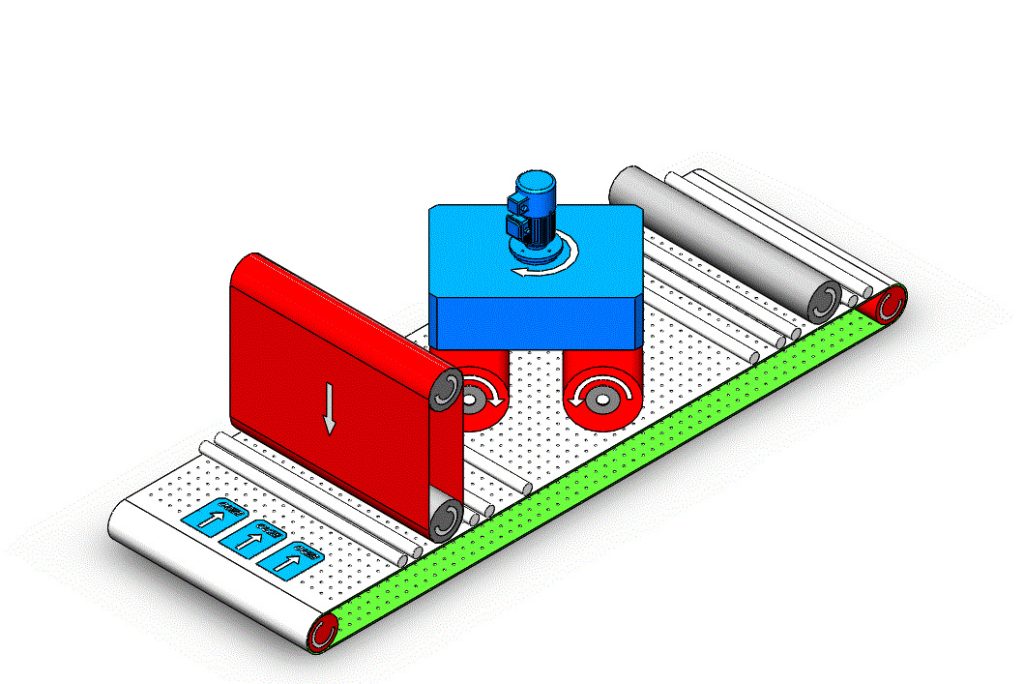

- In the first station – Grinding Belt(R station) of the finishing machine,burrs and imperfections are removed with a grinding belt, resulting in a flat, burr-free surface.

- After grinding,the Multibrush(W station), wich ensures your product is perfectly finished. The six brushes provide a non-directional finish and round the edges with a radius of 2+ mm, giving the product a high-quality and durable appearance.

- The 3rd station Roller Brush (for r station), The roller brush inside the バリ取り機 contacts the surface of the workpiece through the high-speed rolling bristles, and uses the elasticity and friction of the bristles to remove burrs and uneven areas on the workpiece surface.508 RWr Deburring Machine offers the possibility for full ERP control and seamless integration into automated production processes.

Wide belt & Rotary brush & Roller Brush

Metal finishing machine for brushing and polishing

Deburring & Polishing

No.3, No.4 Finishing

Hairline Finishing

バリ取り機 Basic Prameters

Available width:

300/450/630/800/1000/1300/1500/1600 mm

Available thickness:

0.5-100 mm

Feeding speed:

0.5-8 m/min

Rotation speed of rotary brush:

9-21 r/s

Rotary brush size:

300*300 / 300*400 mm

Edge rounding range:

R 0.1-1.0 mm

Worktable:

900 – 980 mm

Minimum processing size:

30*30 mm (Magnetic)

50*50 mm (Vacuum)

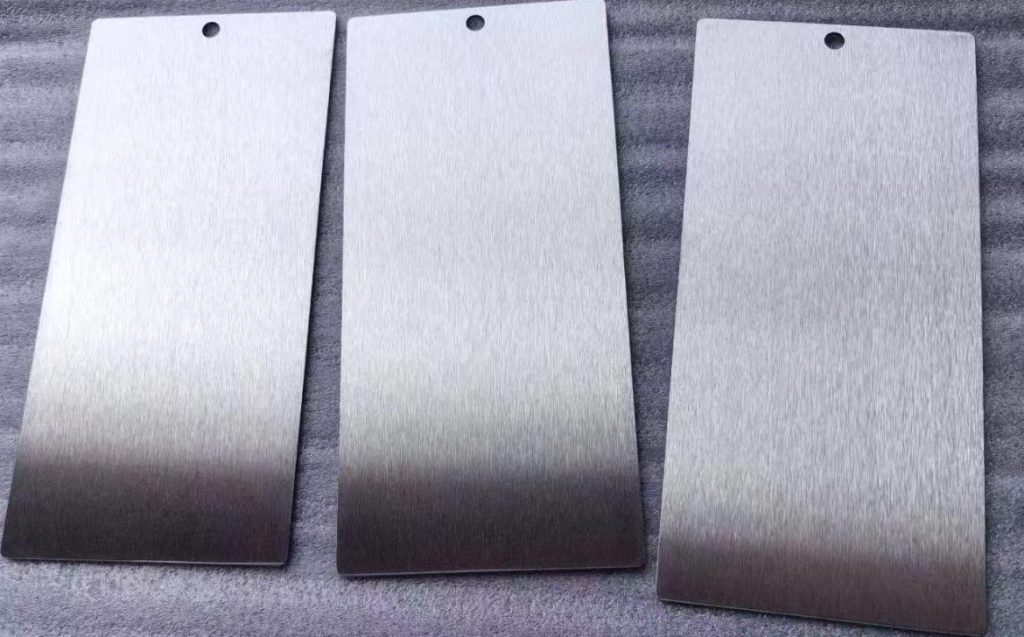

Finished product after deburring

508 RWr Deburring Machine FAQ

バリ取り、エッジラウンド、表面仕上げを1台の機械や工程で行うことはできますか?

Yes, deburring(wide grinding belt), edge rounding(rotary brush), and surface finishing(roller brush) can all be done by a single machine, the ADV® 508RWr. This 3-stage machine is single-sided and can even process sheet metal parts as small as 0.5 x 0.5mm. The 3 stages are comprised of a grinding belt for deburring, rotary brushes for edge rounding and a fleece belt for surface finishing.

What materials are suitable for ADV® 508RWr 板金バリ取り機?

The ADV® 508RWr can process a wide array of metal alloys.These alloys include steel,aluminum,brass,copper,titanium,stainlesssteel and even specialty alloys.

なぜ金属部品からレーザー酸化物を除去することが重要なのですか?

酸素パワー・レーザーで切断すると、切断端に沿ってレーザー酸化物が生成される。このレーザー酸化物がパーツの側面に付着すると、塗装の付着が妨げられ、溶接がより困難になります。したがって、切断端に沿ってレーザー酸化物を除去することは、塗装や溶接などの下流工程を大幅に改善します。

Why does the automatic metal deburring machine use a roatary brush to round the edges of metal sheets?

Thanks to the rotary brushes of the ADV® 508RWr, uniform edge rounding for sheet metal can be achieved in a single pass. These rotary brushes can achieve an edge rounding result of up to 2 mm along all edges for a wide variety of metal alloys.

その他の製品

508 M300 手動バリ取りは、特殊な製品や少量生産に必要です。製造業者は、自動機の長時間に及ぶプログラミング工程を省くことができます。また、半自動装置では壊れやすい部品を滑らかに仕上げるには、より良い方法です。

3 blet grinidng machine to deburr after laser cutting.The purpose of finishing is to enhance quality and visual appeal of the metal sheet parts while also contributing to their protection.Blet grinidng machine to deburr after laser cutting.The purpose of finishing is to enhancing the quality and visual appeal of the metal sheet parts while contributing to their protection.均一な仕上げを保証し、表面上のコーティング、塗料、その他の材料の接着を向上させるのに役立ちます。

2 blet grinidng machine to deburr after laser cutting.ADVの高度な仕上げ機により、金属板部品に様々な仕上げを施すことができます。適切な研磨ベルトを適切な速度と組み合わせて使用することで、直線仕上げや無方向仕上げなど、お好みに合わせて金属板部品を仕上げることができます。

金属シート部品のブラッシングとpolishing.FinishingのためのRr金属仕上げ機は、滑らかで、審美的に魅力的な外観を与えるために、シート部品の表面を丸め、洗練するプロセスを指します。