![]() 24h customer hotline +86 15395181370

24h customer hotline +86 15395181370

商品詳細

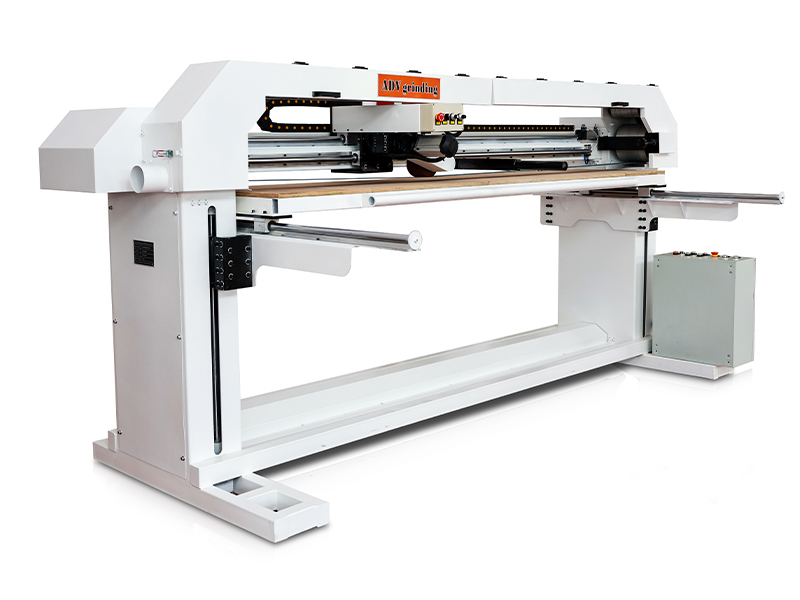

Long Belt Sanding Machine,1 or 2 abrasive belt stations .

- Twin long belt sanding machine for metal sheets or welded structures weld grinding and finishing.

- 金属板または溶接構造物の溶接研磨および仕上げ。

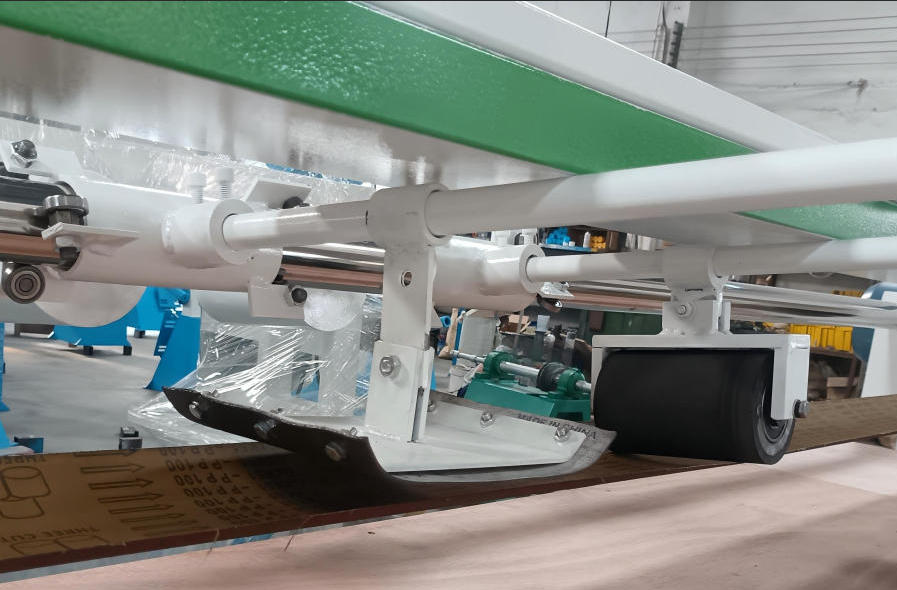

- The ADV MS SANDER is a long belt sanding machine with a flexible abrasive belt that enables flat surface finishing, as well as corners or the edges of materials.

- The MS Sander has a (999→3500)x800mm working table which makes it possible to finish large structures.

- This machine is ideal for irregular shapes polishing as well as for weld removal. The flexible and adjustable table is useful when, because of the large dimensions of the materials to be finished, you are unable to move the piece.

- With the MS BELT GRINDER you move the table by motor and use the adaptability of the long belt together with several grinding tools to finish the areas you need.

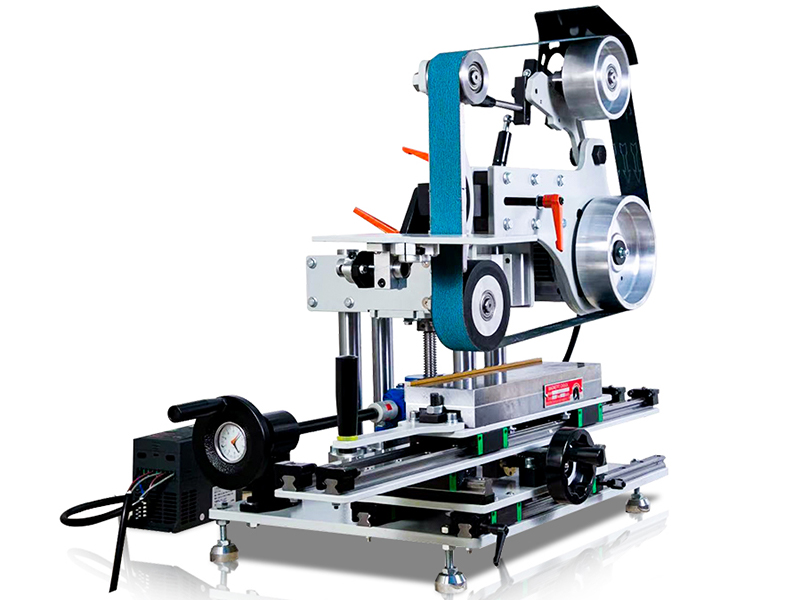

Interchangeable finishing tools

- Single carrier in counterweight system with an easy clamping to use the flat finishing tool or the contact roller.

- double abrasive belt station with

contact roller to reduce interchange

steps and optimize operator time

Control panel

The Long Belt Sanding machine has a control panel at the center of the table, making it easy for the operator to adjust level of the table or the speed abrasive belt.

TECHNICAL DETAILS:

| いいえ | 項目 | 仕様 |

| 1 | モデル | ADV MS-2000*1000 |

| 2 | 利用可能な長さ | 2000 mm |

| 3 | 使用可能幅 | 800 mm |

| 4 | Available height | 650 mm |

| 5 | Sanding belt motor power | 3 kW (Variable frequency drive) |

| 6 | Hairline polishing wheel motor power | 1.2 kW (Variable frequency drive) |

| 7 | Lifting motor power | 0.75 kW |

| 8 | Abrasive Belt rotation speed | 1400 rpm |

| 9 | Wire drawing wheel speed | 1400 rpm |

| 10 | Machine size | 3200*1750*1800 mm |

| 11 | Machine weight | 1000 kg |

Machine standard model:

| Machine model | Workbench area | Lifting height | Abrasive belt motor power |

| ADV MS3700 | 990*610mm | 300mm | 2.2kW |

| ADV MS4000 | 1200*610mm | 300mm | 2.2kW |

| ADV MS4600 | 1450*610mm | 300mm | 2.2kW |

| ADV MS5950 | 2200*610mm | 300mm | 3kW |

| ADV MS6500 | 2500*610mm | 300mm | 3kW |

| ADV MS7600 | 3000*610mm | 300mm | 3kW |

| ADV MS8500 | 3500*610mm | 300mm | 3kW |

The Video of Long Belt Sanding Machine

- Surface finishing and weld grinding of flat surfaces and corners

- abrasive belt tension is exerted

pneumatically. It enables different

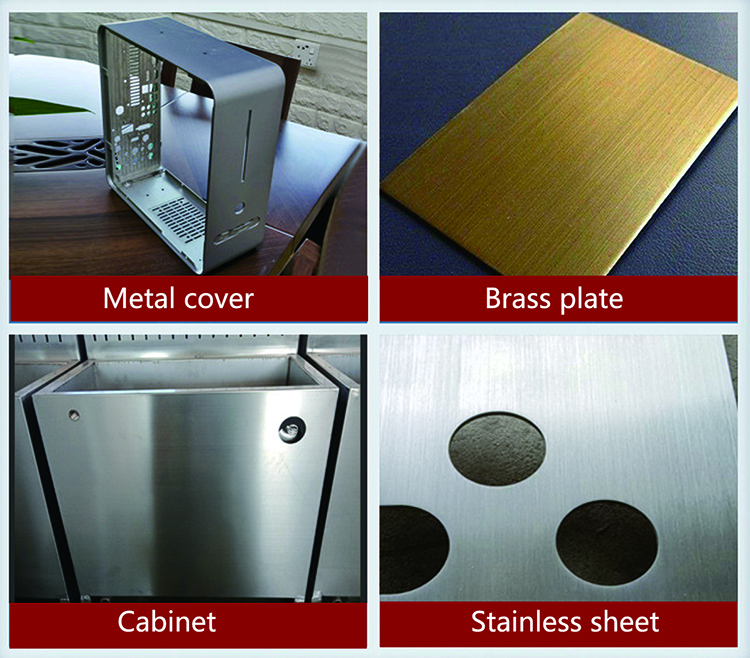

levels of belt tensioning - Metal surface grinding, brushing, pattern sweeping treatment, various metal sheets, metal boxes, and other surface brushed treatments, after the workpiece is processed, the surface is clean and smooth, and the surface texture is clear, which greatly improves the aesthetics and increases the product selling point.

STANDARD EQUIPMENT

_ Double abrasive belt station

_ Flat grinding tool and contact roller on counter

_ weight system

_ Flat manual grinding pad

_ Pneumatic belt tensioning,variable abrasive belt speed and motorized height adjustment

AVAILABLE ACCESSORIES

_ Deburring and edge rounding tool

_ Handling clamping device for 3D parts

_ Dedicated rack for handling device/table storage

_ Second tool carrier in counterweight system

_ Free area below table

Flexible handling of metal surfaces (flat and curved) :

その他の製品

116-9 belt grinder's rotating wheel is made of pure aluminum, with good precision and balance.

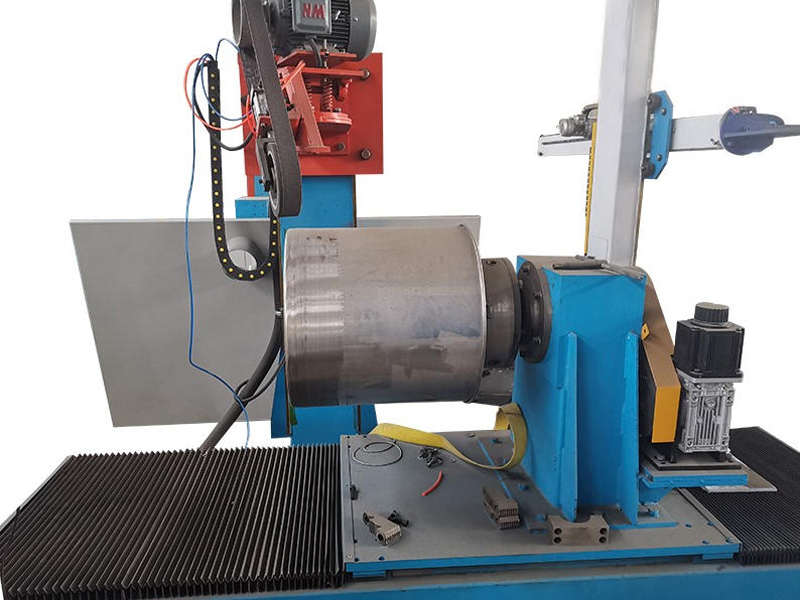

この機械は、皿端マンホールの外部と内部の研削と研磨のために設計されています。VFD制御、PLC制御、CNC制御があり、生産性の異なる要求に対応できます。タンクの使用可能な標準直径は300ミリメートル-3000ミリメートルまたはカスタマイズされます。皿頭楕円研磨機は、広く医療分野、化学、環境浄化、食品、調理器具、飲料、浄水器などに使用されています。

The machine is designed for tank external and internal grinding and polishing. It has VFD control, PLC control, and CNC control according to your different requirements on productivities.

The available standard diameter for the tank is 219mm-3000mm or customized. CNC cylinder polishing machine is widely used in medical area,chemical,environmental purification,food,beverage and water filter,etc.

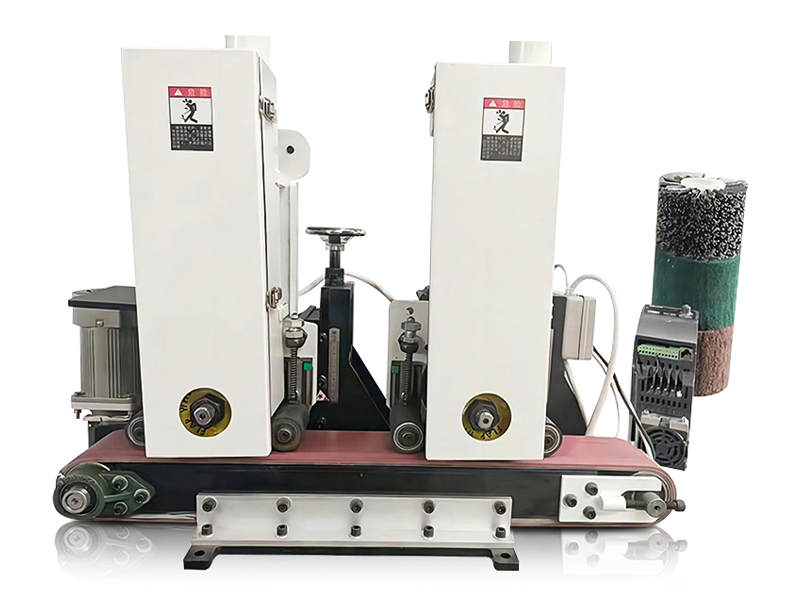

ADV 118-1 or 118-2 metal flat sheet polishing brushing machine.mainly used for flat surface finishing applications, finishing and deburring of strips, satin and bright finishing of square tubes pipes.with sand belt to sweep the scratch line and sand-holes on the surface of the work piece(No.4 finish)