![]() 24h customer hotline +86 15395181370

24h customer hotline +86 15395181370

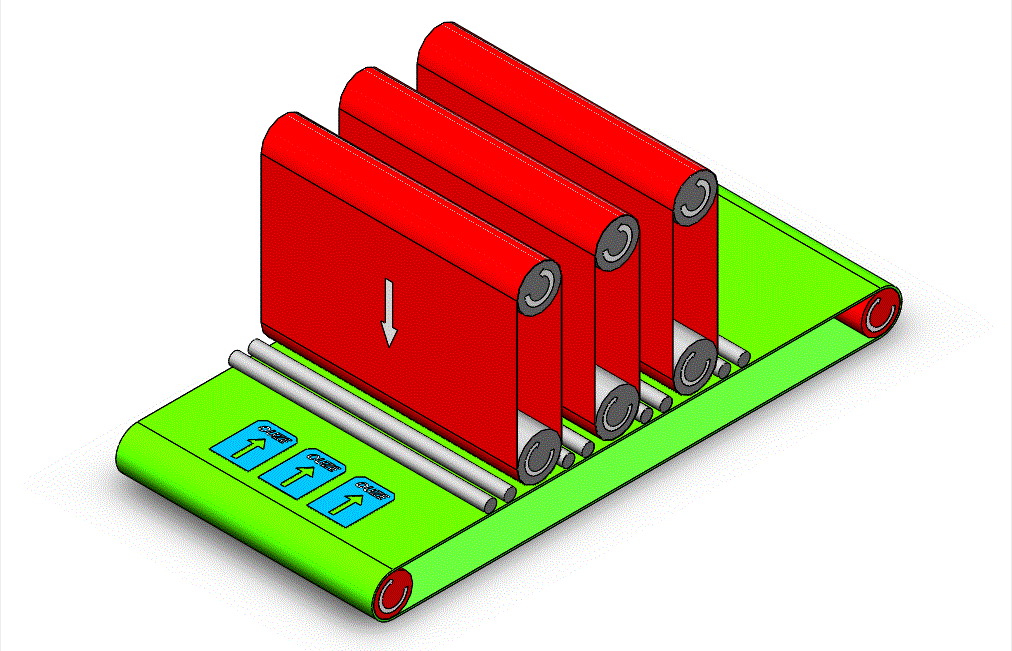

ADV® 508-RRR

Dettagli del prodotto

Wet or Dry Deburring and Finishing Machine – Wide Belt & Wide Belt & Wide Belt(3 blet grinidng machine to deburr after laser cutting)

- Effective processing width : 300/630/800/1000/1300/1600mm(11.8″/24.8″/31.5″/39.4″/51.2″/63″)

- Effective processing thickness: 0.5-100mm(0.02-3.9”)

- Conveying speed: 0.5-10m/min

- Minimum werkpiece size : 280mm

- Processing : Dry or wet

- Multi-station surace Roughness inspection : ≤0.1um

DEBURRING / Oxide Removal / Surface Finish

The ADV 508 RRR wet or dry deburring-Primarily designed for comprehensive surface treatment, this equipment performs metal finishing, laser oxide layer removal, polishing, and other processes. It effectively removes burrs, weld spots, and imperfections from operations like punching, shearing, and laser cutting in a single pass. This ensures safe, reliable processing, achieving a high-quality finish for workpieces.

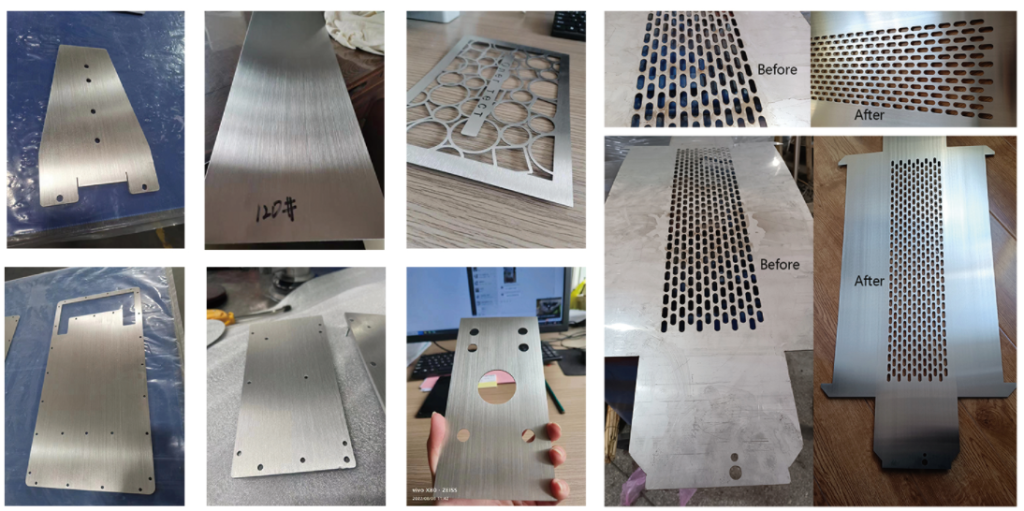

Stainless steel , aluminum , carbon steel , coated workpiece , galvanized plate , copper plate

Why choose wet deburring?

The whole grinding process is carried out in a wet state, which effectively avoids deformation of the product due to overheating, and the grinding effect is good, safe and efficient.Choosing a wet deburring machine has several advantages, particularly for applications that involve heavy-duty or high-speed processing.

Wet deburring effectively reduces dust and airborne particles, enhancing workplace safety and air quality. The cooling effect of water also prevents overheating, making it suitable for heat-sensitive materials and maintaining consistency in abrasive performance.

Additionally, wet deburring often leaves a cleaner, smoother surface finish, especially for intricate or highly polished workpieces.

Altri prodotti

Con le avanzate macchine di finitura ADV è possibile applicare diverse finiture ai pezzi in lamiera. Utilizzando i nastri abrasivi giusti in combinazione con la velocità appropriata, è possibile rifinire i pezzi in lamiera secondo le proprie preferenze, ad esempio con una finitura lineare o non direzionale.

La finitura di parti in lamiera si riferisce al processo di arrotondamento e affinamento delle superfici delle parti in lamiera per conferire loro un aspetto liscio ed esteticamente gradevole.