![]() Hotline clienti 24 ore su 24 +86 15395181370

Hotline clienti 24 ore su 24 +86 15395181370

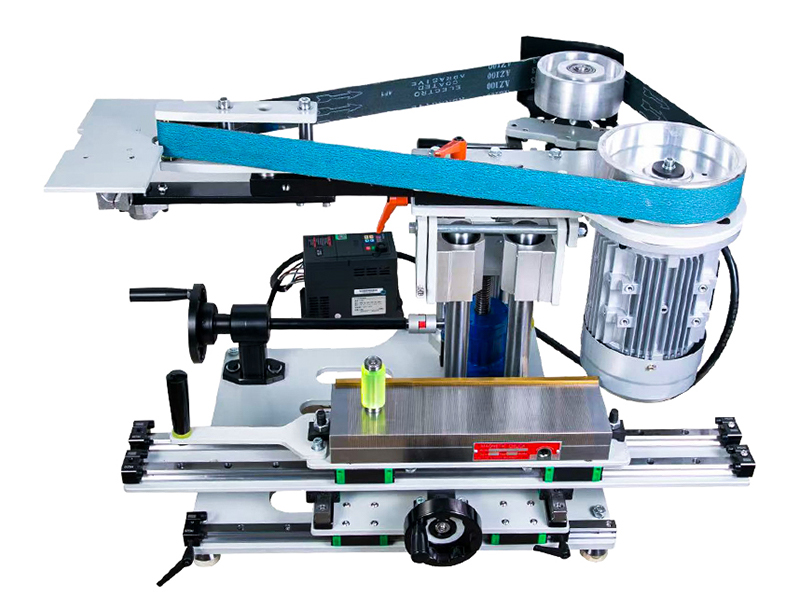

ADV ® 116-9

Dettagli del prodotto

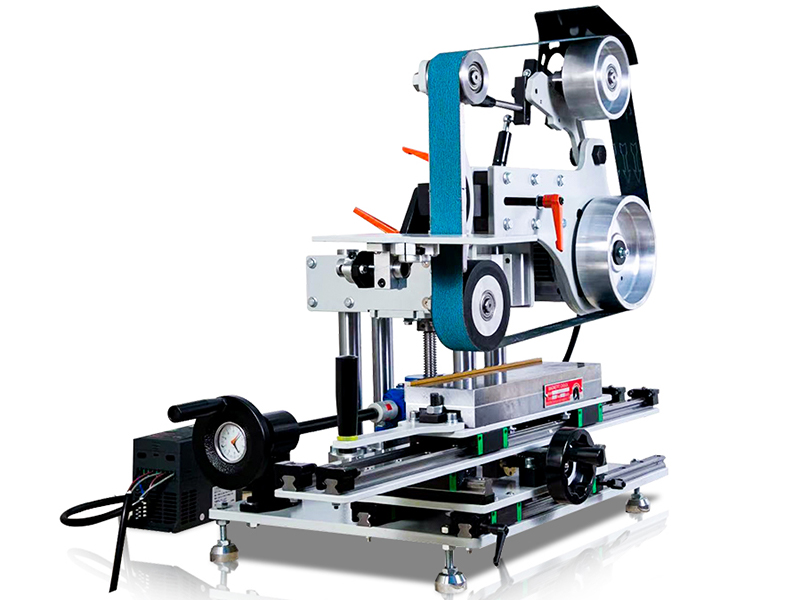

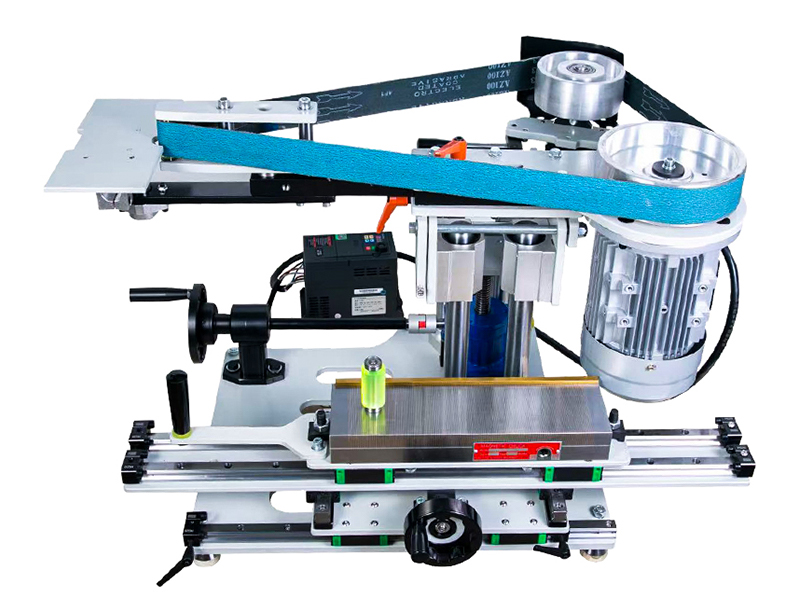

Macchina smerigliatrice a nastro

- Levigatrice a nastro economica per il fai da te

- Macchina per la rettifica dei nastri dei coltelli

- La levigatrice a nastro 116-9 è una versione aggiornata della levigatrice a nastro 116-1 e della levigatrice a nastro 116-8, più comoda e flessibile da utilizzare.

- Velocità regolabile per controllare il processo di levigatura, dalla sgrossatura alla finitura.

- Le molteplici opzioni di grana consentono di scegliere i tipi di carta vetrata per diversi livelli di rimozione del materiale e di levigatezza della superficie.

- Tavoli o aree di lavoro di grandi dimensioni per garantire stabilità e supporto, soprattutto nei modelli fissi.

- Struttura resistente per sopportare un uso intensivo in ambienti industriali o professionali.

Il video della smerigliatrice a nastro 116-9 :

Parametro della macchina smerigliatrice a nastro:

- scatola di legno: 25 kg

- dimensioni dell'imballaggio: 900x600x600

- Configurazione standard: mola piatta in ferro 68×55 mm

- ruota in gomma: 120×50 mm

- rotella per scanalature a dito: 20/30 pezzi

- potenza del motore: 1,5 kW inverter

- potenza: 2,2 kW

- velocità: 2800 giri/min.

- dimensione del nastro di sabbia: 1800×50 mm

- dimensione del tavolo magnetico: 350×100

- Corsa di lavoro del tavolo magnetico: 350x100x30

- dimensioni della macchina: 900x600x800

- peso netto: 135 kg

Macchina smerigliatrice a nastro FAQ

Perché la smerigliatrice a nastro macchina vibra così tanto e si muove dopo averla avviata?

Il motivo principale è che il bilanciamento della ruota rotante non è buono. La ruota rotante comprende una ruota di gomma, una ruota di guida e una puleggia del motore. La macchina vibra se una delle tre ruote rotanti ha una scarsa precisione e un cattivo bilanciamento. Un'altra ragione è che il gioco tra le parti della ruota di supporto è troppo grande, causando movimenti relativi tra le parti e vibrazioni. Un altro motivo è che il motore non è fissato bene, il che provoca vibrazioni.

La ruota rotante della nostra smerigliatrice a nastro è realizzata in alluminio puro, con buona precisione e bilanciamento. Le parti di assemblaggio sono prodotte secondo gli standard, si incastrano senza spazi vuoti e la macchina vibra poco.

Perché la smerigliatrice a nastro fa molto rumore quando inizia a funzionare?

Il rumore causato dal funzionamento dell'apparecchiatura è dovuto principalmente alla mancanza di rigidità della base e delle parti di supporto, all'ampio divario tra le parti abbinate (alcuni produttori hanno attrezzature di lavorazione obsolete, una scarsa consapevolezza della gestione della qualità, una scarsa qualità delle parti prodotte e quasi nessun requisito di tolleranza di abbinamento), all'uso di cuscinetti di bassa qualità e alla velocità troppo elevata del nastro abrasivo.

Le nostre parti di base hanno una buona rigidità, gli ingegneri rispettano rigorosamente le tolleranze e i cuscinetti e i nastri abrasivi sono tutti accessori di alta qualità. Il rumore è ridotto durante il funzionamento e la velocità di rotazione è stabile e uniforme.

Altri prodotti

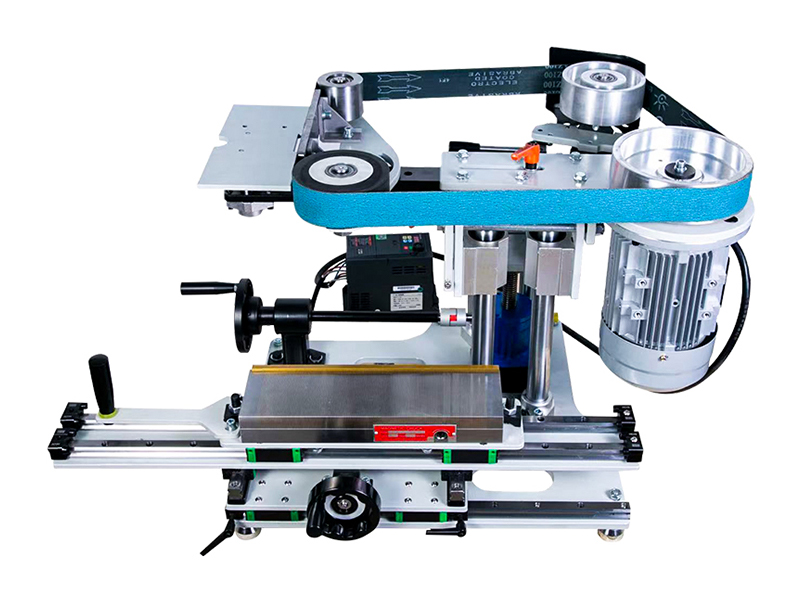

Smerigliatrice a nastro ad alte prestazioni con robusta base della macchina.Smerigliatrice a nastro abrasiva consigliata per: Levigare le bave sul metallo, smussare i bordi per la saldatura e rifinire le fusioni, tra gli altri usi.

La macchina a nastro di sabbia spinta a mano (levigatrice a nastro per lamiera) è adatta per la levigatura di saldature di pezzi di grandi dimensioni, superfici, macchina di finitura a nastro lungo.

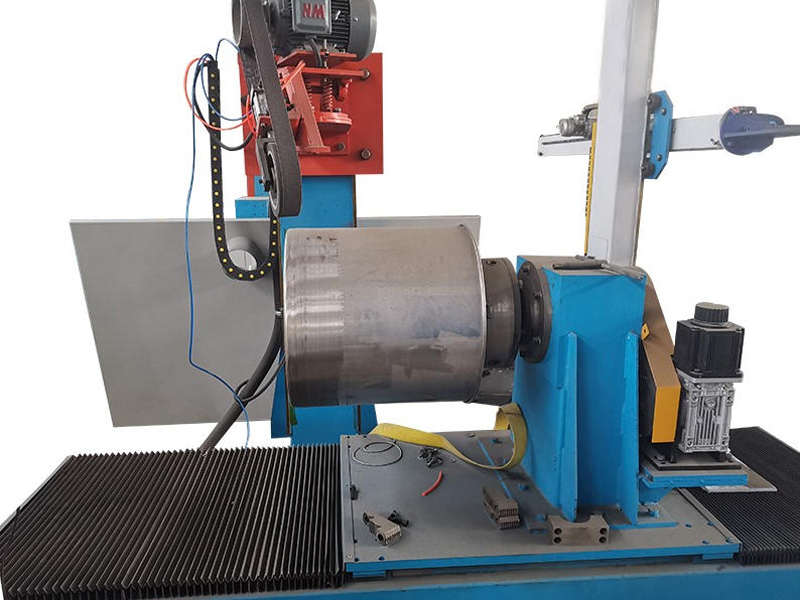

La macchina è progettata per la rettifica e la lucidatura esterna e interna dei chiusini. Dispone di controllo VFD, controllo PLC e controllo CNC in base alle diverse esigenze di produttività. Il diametro standard disponibile per il serbatoio è 300mm-3000mm o personalizzato. La macchina per la lucidatura ellittica della testa del piatto è ampiamente utilizzata nel settore medico, chimico, della purificazione ambientale, alimentare, delle stoviglie, delle bevande e del filtro dell'acqua, ecc.

La macchina è progettata per la rettifica e la lucidatura esterna e interna dei serbatoi. Dispone di controllo VFD, controllo PLC e controllo CNC in base alle diverse esigenze di produttività.

Il diametro standard disponibile per il serbatoio è di 219 mm-3000 mm o personalizzato. La macchina per la lucidatura dei cilindri CNC è ampiamente utilizzata in ambito medico, chimico, di purificazione ambientale, alimentare, delle bevande e del filtro dell'acqua, ecc.