![]() 24h customer hotline +86 15395181370

24h customer hotline +86 15395181370

Flat Metal Polishing Machine

- Irregular Pattern Polishing

Transform polished stainless steel into high-end decorative panels with this 506 Multi-Pattern Texturing Machine. Engineered for SS200/300/400 series sheets (0.5-4mm thickness), its 5-vibration-head design generates precision textures:

- Coarse Random Grain Finish (coarse random)

- Fine Linear Brushed Finish (micro-pattern)

- Sandblasted Random Grain (sandblast simulation)

- Water Ripple Effect Finish (3D wave effects)

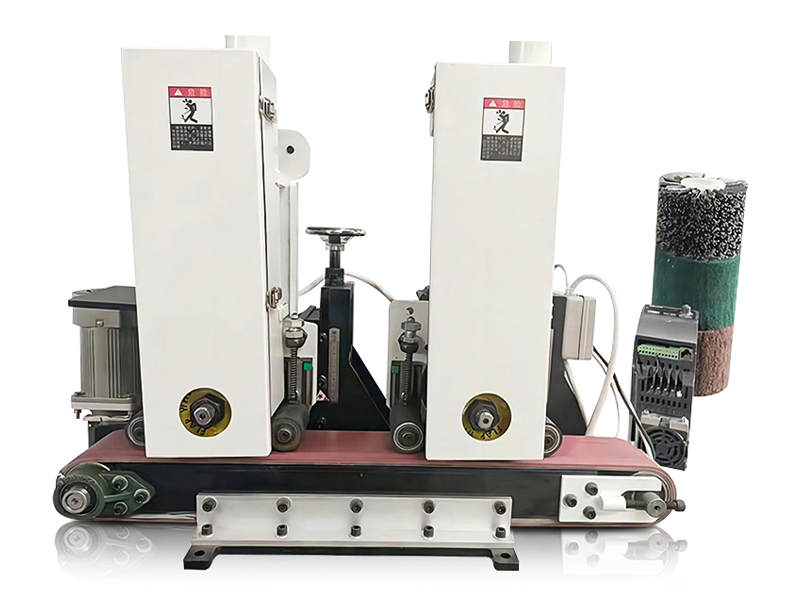

- Flat Metal Polishing Machine

These machines use a reciprocating motion to sand or polish workpieces, making them ideal for both flat and contoured surfaces.At ADV Machinery, you’ll find buffing grinders and belt grinders for weld removal, grinding, and polishing of aluminum, mild steel, and stainless steel parts. With our selection of polishing lathes, ADV Machinery has the metal finishing equipment to meet your buffing or belt grinding needs.

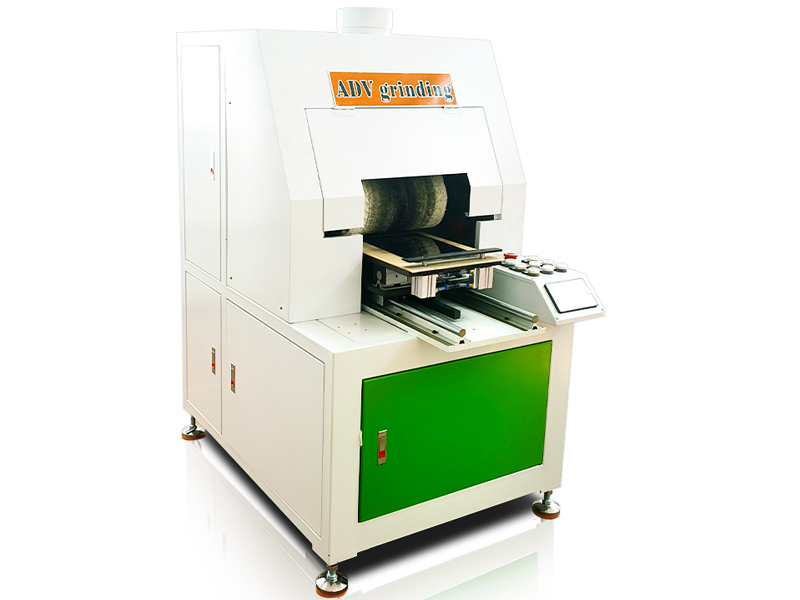

- Wheel Polishing Machine

Revving Up Shine: The Wheel Polishing Machine Advantage

- Aesthetic Polishing:

The most common application, used to enhance the appearance of automotive wheels. Wheel polishing machines remove surface imperfections, enhancing the shine and aesthetics of the wheels. - Oxidation Removal:

After aging or extended use, automotive wheels may develop oxidation layers. Wheel polishing machines are employed to remove these oxidation layers, making the wheels look cleaner and fresher. - Corrosion Reduction:

Polishing helps reduce corrosion on the wheel’s surface, particularly in harsh weather conditions, thus extending the wheel’s lifespan.

- Polishing Machine4

Classify and describe the test copy…

- Polishing Machine5

Classify and describe the test copy…

- Polishing Machine6

Classify and describe the test copy…