![]() Đường dây nóng hỗ trợ khách hàng 24/7: +86 15395181370

Đường dây nóng hỗ trợ khách hàng 24/7: +86 15395181370

Máy đánh bóng

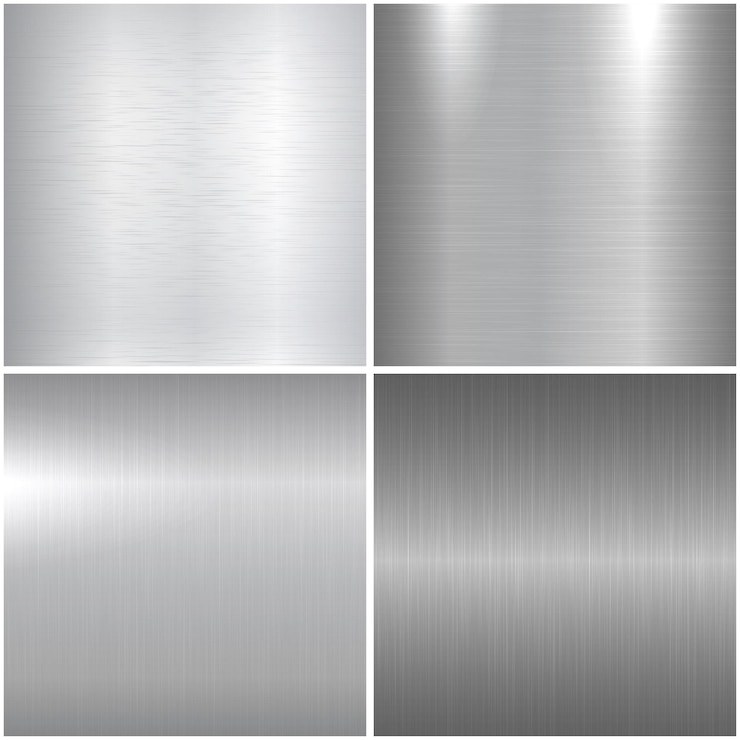

Máy đánh bóng kim loại tấm của ADV®. Máy chủ yếu được sử dụng để đánh bóng thép không gỉ, tấm nhôm, tấm kim loại và bề mặt phẳng, v.v.

Hãy liên hệ với chúng tôi ngay hôm nay!

Máy đánh bóng kim loại là thiết bị thiết yếu trong các xưởng sản xuất và nhà máy, được thiết kế để chuyển đổi bề mặt kim loại từ trạng thái thô ráp hoặc mờ nhạt thành bề mặt bóng loáng, tinh tế. Dải sản phẩm rất đa dạng, đáp ứng các yêu cầu đa dạng:

Cho các môi trường đòi hỏi khắt khe: Máy đánh bóng kim loại công nghiệp và máy đánh bóng kim loại công suất lớn được thiết kế để hoạt động liên tục trong nhà máy và sản xuất quy mô lớn. Các hệ thống này có khả năng xử lý khối lượng công việc lớn, thường được trang bị động cơ mạnh mẽ, cấu trúc bền bỉ và các tính năng hỗ trợ sản lượng cao. Máy đánh bóng và đánh bóng công nghiệp tập trung đặc biệt vào việc đạt được bề mặt sáng bóng như gương thông qua các giai đoạn đánh bóng liên tiếp.

Quy mô và Ứng dụng: Từ các máy đánh bóng kim loại công nghiệp cỡ lớn tự động hóa toàn bộ dây chuyền sản xuất đến các máy đánh bóng kim loại bàn làm việc nhỏ gọn và các máy nhỏ. Máy đánh bóng kim loại Phù hợp cho các xưởng sản xuất, thử nghiệm mẫu, có máy móc phù hợp cho mọi không gian và nhiệm vụ. Máy đánh bóng kim loại cầm tay (bao gồm các lựa chọn máy đánh bóng kim loại cầm tay tốt nhất) mang lại sự linh hoạt tối đa cho các công việc phức tạp, bề mặt cong hoặc đánh bóng điểm. Để đạt kết quả đồng đều và năng suất cao, máy đánh bóng kim loại tự động giảm thiểu sự can thiệp thủ công.

Hoàn thiện chuyên nghiệp: Các ứng dụng cụ thể đòi hỏi các giải pháp được tùy chỉnh. Máy đánh bóng tấm kim loại và máy đánh bóng tấm kim loại phẳng được tối ưu hóa cho các tấm kim loại lớn, phẳng, trong khi máy đánh bóng tấm kim loại dày xử lý các vật liệu dày hơn. Máy đánh bóng mẫu kim loại là thiết bị quan trọng trong các phòng thí nghiệm kim loại học và kiểm soát chất lượng để chuẩn bị mẫu cho phân tích vi mô. Máy đánh bóng bề mặt kim loại bao quát mục tiêu chung của tất cả các thiết bị này: đạt được chất lượng bề mặt thẩm mỹ và chức năng mong muốn.

Các thành phần chính: Quá trình đánh bóng hiệu quả phụ thuộc vào việc sử dụng đúng các công cụ đánh bóng kim loại. Máy móc sử dụng các loại bàn chải đánh bóng kim loại khác nhau (sisal, vải, chứa chất mài mòn), bánh xe đánh bóng, dây đai, đĩa và hợp chất. Các công cụ đánh bóng kim loại nhỏ thường được sử dụng kết hợp với các thiết bị cầm tay để thực hiện các công việc chi tiết.

Tìm kiếm thiết bị phù hợp: Dù bạn đang tìm kiếm máy đánh bóng kim loại tốt nhất cho một nhiệm vụ cụ thể hay đang xem xét các tùy chọn máy đánh bóng kim loại thông dụng đang được bán, hãy cân nhắc các yếu tố như khối lượng công việc, loại vật liệu, độ bóng mong muốn, không gian sẵn có và ngân sách. Máy mài kim loại Giá cả có sự chênh lệch đáng kể tùy thuộc vào kích thước, công suất, mức độ tự động hóa và thương hiệu. Các tùy chọn đa dạng sẵn có, từ các mô hình máy đánh bóng kim loại công nghiệp hạng nặng đến các máy đánh bóng kim loại cầm tay đa năng và các loại máy chuyên dụng. Máy mài kim loại tấm.

Tóm lại, máy đánh bóng kim loại, từ các hệ thống công nghiệp mạnh mẽ đến các thiết bị nhỏ gọn để bàn hoặc cầm tay, cung cấp lực, tốc độ và khả năng kiểm soát cần thiết để đạt được bề mặt hoàn thiện chuyên nghiệp, nâng cao vẻ ngoài, cải thiện khả năng chống ăn mòn và chuẩn bị bề mặt kim loại cho các công đoạn gia công tiếp theo hoặc sử dụng cuối cùng.

- Mài bóng theo mẫu không đều

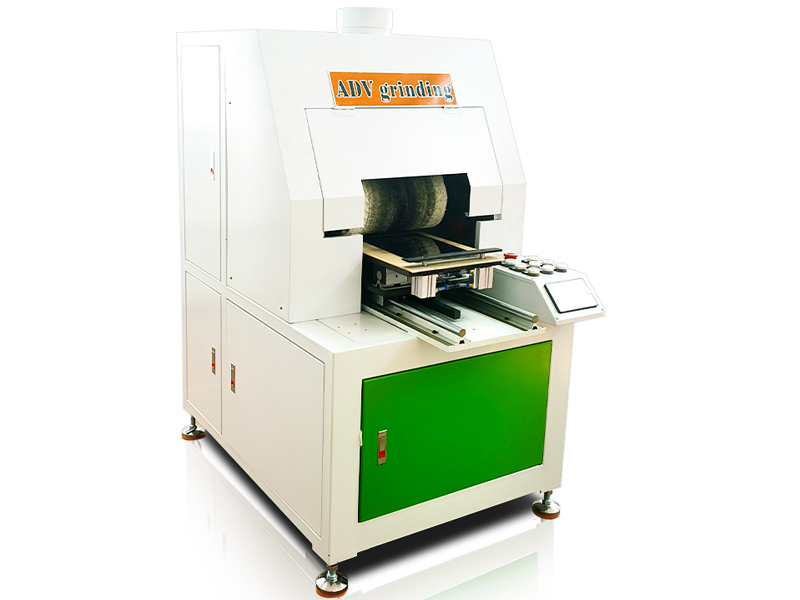

Biến thép không gỉ đánh bóng thành các tấm trang trí cao cấp với sản phẩm này. Máy tạo hoa văn đa mẫu 506Được thiết kế dành cho các tấm thép series SS200/300/400 (độ dày 0,5-4mm), thiết kế 5 đầu rung của nó tạo ra các hoa văn chính xác:

- Bề mặt hạt thô ngẫu nhiên (ngẫu nhiên thô)

- Bề mặt chải mịn tuyến tính (mô hình vi mô)

- Bề mặt được phun cát với vân ngẫu nhiên (Mô phỏng phun cát)

- Hiệu ứng sóng nước (Hiệu ứng sóng 3D)

- Máy đánh bóng kim loại phẳng

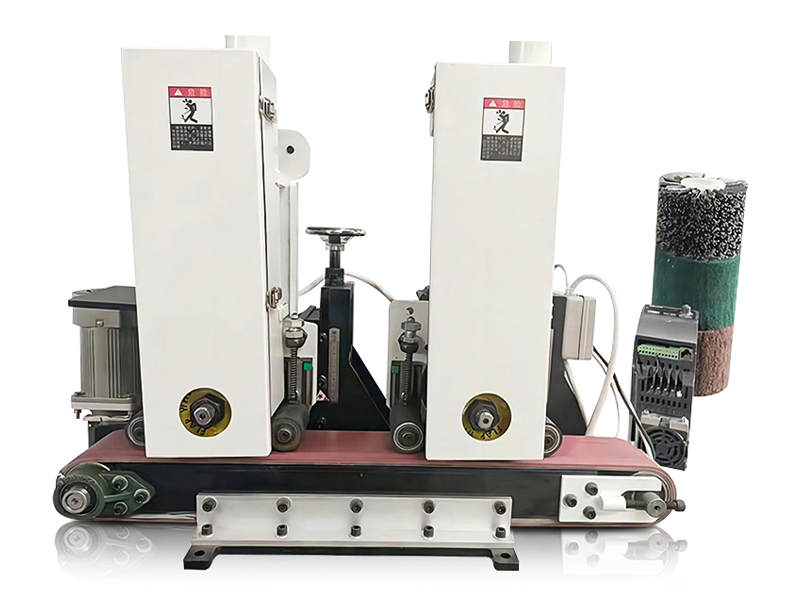

Các máy này sử dụng chuyển động dao động để mài hoặc đánh bóng chi tiết gia công, khiến chúng trở nên lý tưởng cho cả bề mặt phẳng và bề mặt có hình dạng phức tạp. Máy móc ADVBạn sẽ tìm thấy các máy mài đánh bóng và máy mài băng để loại bỏ mối hàn, mài và đánh bóng các bộ phận bằng nhôm, thép carbon và thép không gỉ. Với dòng sản phẩm máy mài đánh bóng của chúng tôi, ADV Machinery cung cấp Xử lý bề mặt kim loại Thiết bị đáp ứng nhu cầu đánh bóng hoặc mài bằng băng của bạn.

- Máy đánh bóng bánh xe

Tăng cường độ bóng: Ưu điểm của máy đánh bóng bánh xe

- Làm bóng thẩm mỹ:

Ứng dụng phổ biến nhất, được sử dụng để nâng cao vẻ ngoài của bánh xe ô tô. Máy đánh bóng bánh xe loại bỏ các khuyết điểm trên bề mặt, làm tăng độ bóng và tính thẩm mỹ của bánh xe. - Loại bỏ quá trình oxy hóa:

Sau quá trình lão hóa hoặc sử dụng lâu dài, bánh xe ô tô có thể hình thành các lớp oxy hóa. Máy đánh bóng bánh xe được sử dụng để loại bỏ các lớp oxy hóa này, giúp bánh xe trông sạch sẽ và tươi mới hơn. - Giảm ăn mòn:

Việc đánh bóng giúp giảm thiểu sự ăn mòn trên bề mặt bánh xe, đặc biệt trong điều kiện thời tiết khắc nghiệt, từ đó kéo dài tuổi thọ của bánh xe.

- Máy đánh bóng 4

Phân loại và mô tả bản sao thử nghiệm…

- Máy đánh bóng 5

Phân loại và mô tả bản sao thử nghiệm…

- Máy đánh bóng 6

Phân loại và mô tả bản sao thử nghiệm…