![]() Đường dây nóng hỗ trợ khách hàng 24/7: +86 15395181370

Đường dây nóng hỗ trợ khách hàng 24/7: +86 15395181370

The Essential Guide to Deburring Machines and Technologies

Deburring Machines solution – What Are Burrs and Why Do They Matter?

During the manufacturing of metal parts, various processes—such as stamping, grinding, turning, engraving, plasma cutting, blanking, and milling—are often required to shape components into their desired form. However, these processes frequently leave behind small ridges, edges, or protrusions known as burrs. Burrs are not merely a cosmetic issue; they can significantly affect the quality, safety, and functionality of a finished product. Removing these imperfections is critical to ensure that the part meets stringent industry standards.

Common Types of Burrs

Understanding burr formation is essential for choosing the right deburring solution. There are three major types of burrs commonly encountered in metalworking:

- Rollover Burrs: These look like small curls or flares of metal protruding from the component’s edges.

- Poisson Burrs: Accumulated at the end of a part, these burrs typically extend sideways, compromising structural integrity.

- Breakout Burrs: Swelling upward from the surface, these burrs give the appearance that the metal is breaking out from the workpiece.

Each burr type presents unique challenges in removal and can lead to issues such as improper fit, reduced lifespan due to corrosion and stress, safety hazards, and diminished aesthetics.

What Is Deburring?

Loại bỏ ba via is the process of removing these unwanted pieces of metal, thereby eliminating the risks associated with burr contamination. It is not a one-size-fits-all procedure; the selection of deburring methods depends on factors like material type, burr size and location, production volume, and the required finish quality.

Deburring contributes to the following advantages:

- Enhanced safety for material handling and end-users

- Higher quality, more reliable products

- Improved production efficiency

- Lower costs by reducing rework and scrap

- Flexible solutions for diverse manufacturing needs

- Ease of integration into existing workflows

Key Deburring Processes

Several techniques have emerged in the industry for deburring metal components, each with its unique benefits:

Loại bỏ ba via bằng tay

Ideal for low-volume production and small or intricate parts, manual deburring utilizes skilled operators to physically remove burrs with specialized tools. While labor-intensive, this method delivers unmatched control and precision, especially for complex geometries.

Mass Finishing

Mass finishing is commonly deployed for high-volume production runs or delicate pieces. This technique employs dry or wet processes, utilizing equipment such as rotary vibrators, drag finishing machines, or continuous flow installations. It excels in processing batches of parts efficiently and is excellent for achieving consistent finishes.

Brushing

Brushing involves abrasive brushes to scrub away burrs. Suitable for both simple and complex products, this technique is highly compatible with automation and is effective for both initial and final finishing.

Mechanical Deburring

Mechanical deburring, performed by specialized Máy làm sạch bavia, uses grinding or sanding tools to precisely remove burrs. These machines deliver rapid, repeatable results and can be configured to handle various part sizes, shapes, and material compositions.

Advanced Deburring Technology from ADV Machinery

At ADV Machinery, we embody innovation in deburring technology. Our machines support up to four interchangeable heads, offering combinations of oscillating discs, rotating brushes, and abrasive belts for optimal results. Whether your operation demands high-volume efficiency or precision for small, flat, or intricate components, our lineup is adaptable to your production needs.

Our deburring machines are engineered to process a wide range of materials—including challenging stainless steel, lightweight aluminum sheets, or small flat copper parts. We pride ourselves on providing customized solutions that deliver burr-free, premium-quality finishes every time.

Finishing, Polishing, and Graining Solutions

Beyond deburring, ADV Machinery offers extensive finishing, polishing, and graining equipment options. The right solution depends on your material and desired outcome—whether you prioritize aesthetic perfection or enhanced durability. Our technology can elevate the surface quality of virtually any metal component, ensuring that your operation achieves both superior looks and unmatched strength.

Why Invest in a Deburring Machine?

Investing in a quality deburring machine directly impacts your production outcomes:

- Consistency: Automated deburring ensures every part meets exact specifications.

- Speed: Machines outperform manual processes, delivering faster turnaround times.

- Cost Savings: Automation reduces labor costs, rework, and waste.

- Safety: Burr-free parts prevent injuries during assembly and end-use.

- Product Longevity: Smooth surfaces reduce wear, corrosion risk, and increase lifespan.

Choose ADV Machinery for Your Deburring Needs

ADV Machinery stands at the forefront of deburring and finishing technology. Contact us today to discuss your unique requirements, and let our team guide you in selecting the optimal solution for your application. From robust deburring machines to comprehensive polishing systems, ADV delivers quality, efficiency, and reliability for manufacturers worldwide.

Các bài viết khác

- Triển lãm

- Tin tức, Công nghệ

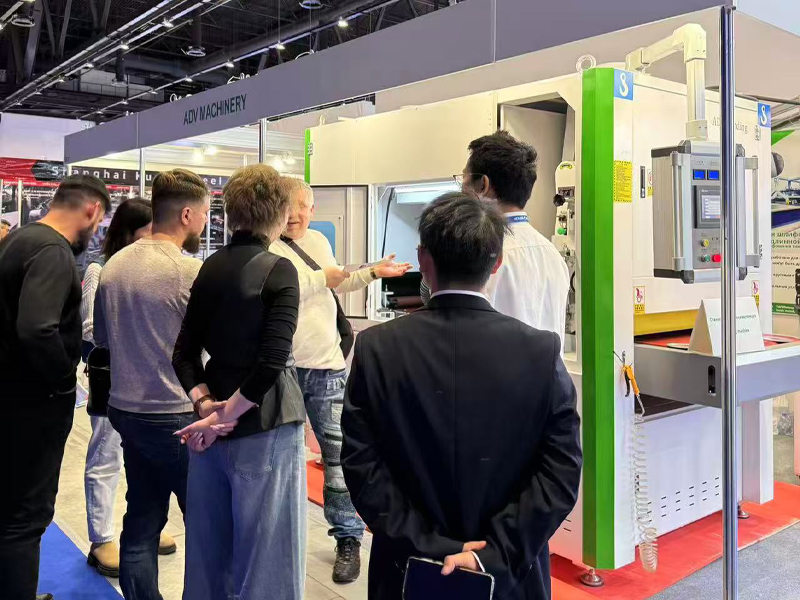

Xử lý bề mặt kim loại 2025 CHICAGO – Triển lãm FABTECH 2025 gần đây tại Chicago đã chứng minh là một nền tảng xuất sắc để giới thiệu công nghệ xử lý bề mặt kim loại tiên tiến, với sự quan tâm đặc biệt tập trung vào máy làm sạch cạnh 508 và hệ thống đánh bóng ống chuyên dụng được trưng bày bởi các nhà lãnh đạo ngành. Sự kiện FABTECH 2025, triển lãm lớn nhất Bắc Mỹ về gia công, chế tạo, hàn và xử lý bề mặt kim loại […]

- Triển lãm, Tin tức