![]() 24h customer hotline +86 15395181370

24h customer hotline +86 15395181370

ADV® 508-RWr

Ürün Detayları

The Video Of The 508 RWr Series Deburring Machine

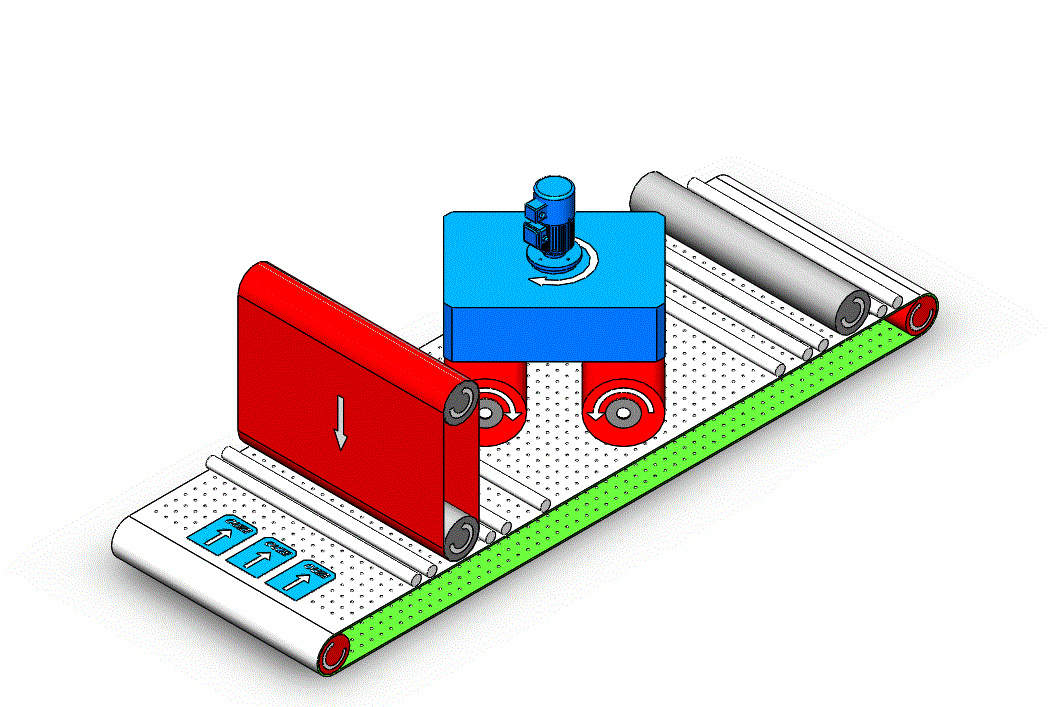

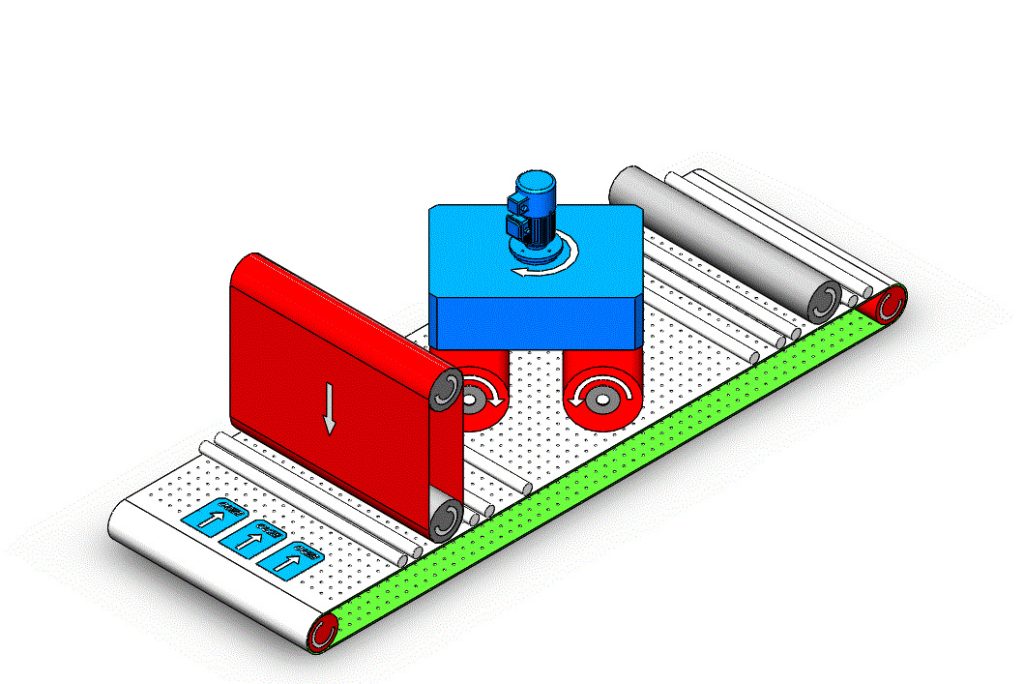

- In the first station – Grinding Belt(R station) of the finishing machine,burrs and imperfections are removed with a grinding belt, resulting in a flat, burr-free surface.

- After grinding,the Multibrush(W station), wich ensures your product is perfectly finished. The six brushes provide a non-directional finish and round the edges with a radius of 2+ mm, giving the product a high-quality and durable appearance.

- The 3rd station Roller Brush (for r station), The roller brush inside the çapak alma maki̇nesi̇ contacts the surface of the workpiece through the high-speed rolling bristles, and uses the elasticity and friction of the bristles to remove burrs and uneven areas on the workpiece surface.508 RWr Deburring Machine offers the possibility for full ERP control and seamless integration into automated production processes.

Wide belt & Rotary brush & Roller Brush

Metal finishing machine for brushing and polishing

Deburring & Polishing

No.3, No.4 Finishing

Hairline Finishing

Çapak Alma Makinesi Basic Prameters

Available width:

300/450/630/800/1000/1300/1500/1600 mm

Available thickness:

0.5-100 mm

Feeding speed:

0.5-8 m/min

Rotation speed of rotary brush:

9-21 r/s

Rotary brush size:

300*300 / 300*400 mm

Edge rounding range:

R 0.1-1.0 mm

Worktable:

900 – 980 mm

Minimum processing size:

30*30 mm (Magnetic)

50*50 mm (Vacuum)

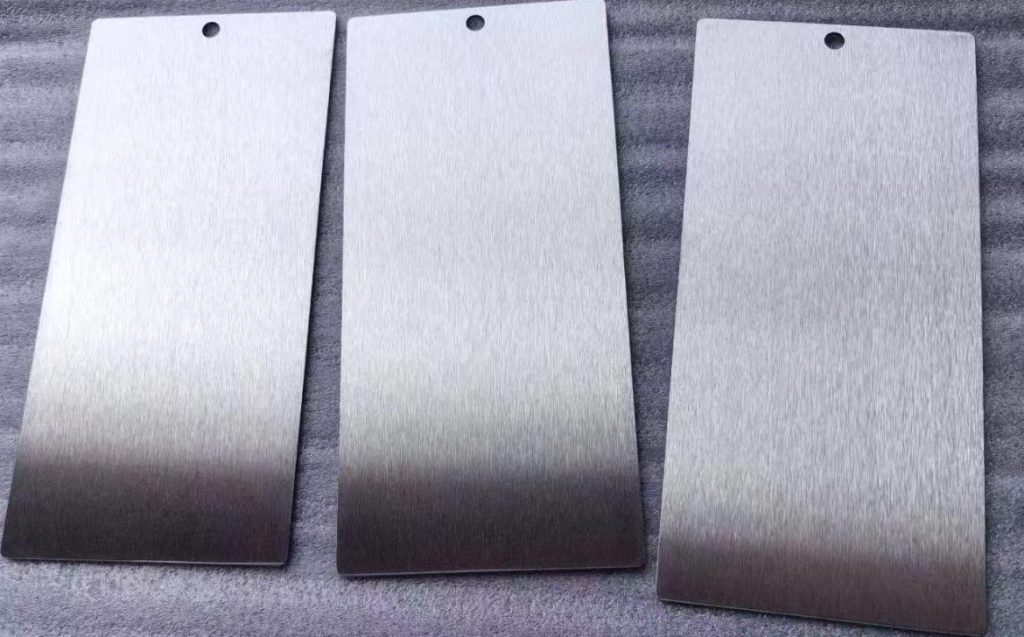

Finished product after deburring

508 RWr Deburring Machine FAQ

Çapak alma, kenar yuvarlama ve yüzey finisajı tek bir makine veya işlemle yapılabilir mi?

Yes, deburring(wide grinding belt), edge rounding(rotary brush), and surface finishing(roller brush) can all be done by a single machine, the ADV® 508RWr. This 3-stage machine is single-sided and can even process sheet metal parts as small as 0.5 x 0.5mm. The 3 stages are comprised of a grinding belt for deburring, rotary brushes for edge rounding and a fleece belt for surface finishing.

What materials are suitable for ADV® 508RWr sac metal çapak alma makinesi?

The ADV® 508RWr can process a wide array of metal alloys.These alloys include steel,aluminum,brass,copper,titanium,stainlesssteel and even specialty alloys.

Metal parçalardan lazer oksidi çıkarmak neden önemlidir?

Oksijenle çalışan bir lazerle kesim yapılırken kesme kenarı boyunca lazer oksit oluşur. Parçaların kenarındaki bu lazer oksit, herhangi bir boya kaplamasının yapışmasını önleyecek ve kaynak işlemini çok daha zor hale getirecektir. Bu nedenle, kesme kenarları boyunca lazer oksitin giderilmesi, boyama ve kaynak gibi sonraki işlemleri büyük ölçüde iyileştirecektir.

Why does the automatic metal deburring machine use a roatary brush to round the edges of metal sheets?

Thanks to the rotary brushes of the ADV® 508RWr, uniform edge rounding for sheet metal can be achieved in a single pass. These rotary brushes can achieve an edge rounding result of up to 2 mm along all edges for a wide variety of metal alloys.

Daha Fazla Ürün

508 M300 Manual deburring is necessary for specialized products or low-volume runs. Manufacturers can skip over the sometimes lengthy programming process of an automated machine. It’s also a better way to ensure a smooth finish on a part that’s too fragile for semi automatic equipment.

3 blet grinidng machine to deburr after laser cutting.The purpose of finishing is to enhance the quality and visual appeal of the metal sheet parts while also contributing to their protection. It ensures a uniform finish and can assist in improving the adhesion of coatings, paint, or other materials on the surface.

2 blet grinidng machine to deburr after laser cutting.With ADV’s advanced finishing machines, you can apply various finishes to your metal sheet parts. By using the right abrasive belts in combination with the appropriate speed, finish your metal sheet parts to your preferences, such as with a linear finish or a non-directional finish.

Fırçalama ve cilalama için Rr Metal son işlem makinesi Metal sac parçaların bitirilmesi, pürüzsüz, estetik açıdan çekici bir görünüm vermek için sac parçaların yüzeylerinin yuvarlanması ve rafine edilmesi sürecini ifade eder. yüzeydeki kusurları, çapakları, pürüzlü kenarları ve diğer istenmeyen özellikleri gidermek.