![]() 24h customer hotline +86 15395181370

24h customer hotline +86 15395181370

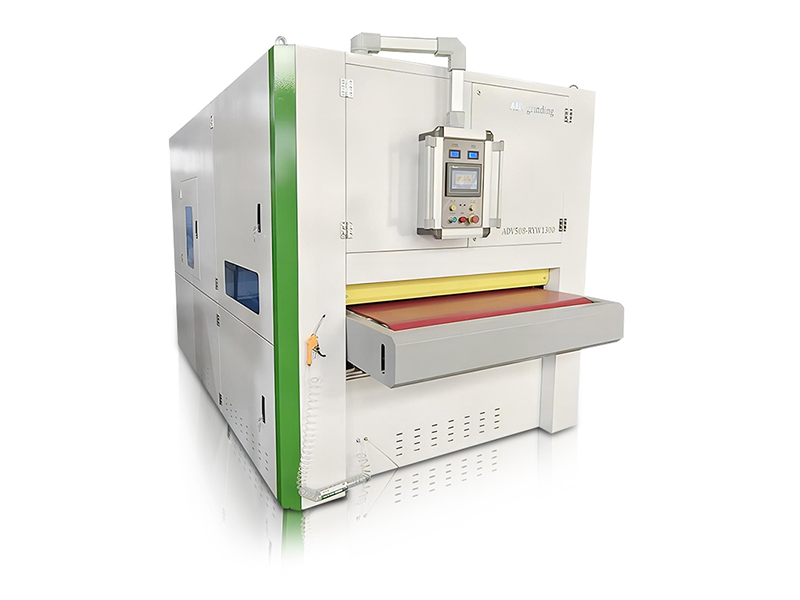

ADV® 508-RW

Ürün Detayları

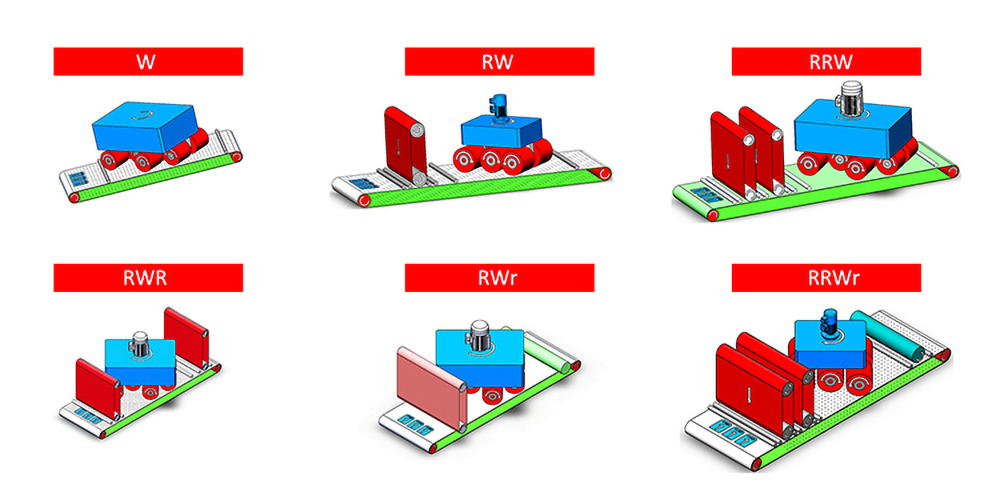

2 Stations : Rotary Brush and Grinding Belt. The 508 RW with dry sanding belt plus universal roller brush combination model. It is mainly used to deal with deburring, chamfering function, workpiece edge, hole deburring treatment. Deburring Machine can be configured in different combinations according to your final surface requirements for the product.

- Drum Deburring Machines : Drum deburring machines use rotating drums to perform abrasive deburring, ideal for batch processing of metal parts.

- Minimum workpiece size :Magnetic suction 30*30 mm, Vacuum suction 50*50 mm

The Station of the 508 RW Çapak Alma Makinesi:

- The 508 RW deburring machine with 2 station .

- Sanding belt removes slag, oxidized skin, large flanging and other burrs on the surface of the workpiece.

- Edge rounding with rotary brushes Rotary brushes offer the most effective and consistent edge rounding results, They make contact with the sheet metal parts from all directions.

| Mevcut genişlik | 300/450/630/800/1000/1300/1500/1600 mm |

|---|---|

| Available thickness | 0.5-100 mm |

| Besleme hızı | 0.5-8 m/min |

| Rotation speed of rotary brush | 9-21 r/s |

| Rotary brush size | 300*300 / 300*400 mm |

| Edge rounding range | R 0.1-1.0 mm |

| Worktable | 900 – 980 mm |

| Minimum processing size | 30*30 mm (Magnetic)

50*50 mm (Vacuum) |

Available model:

508RW Frequently Asked Questions

How to realize burr treatment on the surface of workpiece?

RW with 1 set of wide belt mechanism, the belt rotates at high speed to remove slag particles, oxidized skin, large flanges and other burrs on the surface of the workpiece.

How to realize workpiece edge and hole deburring treatment?

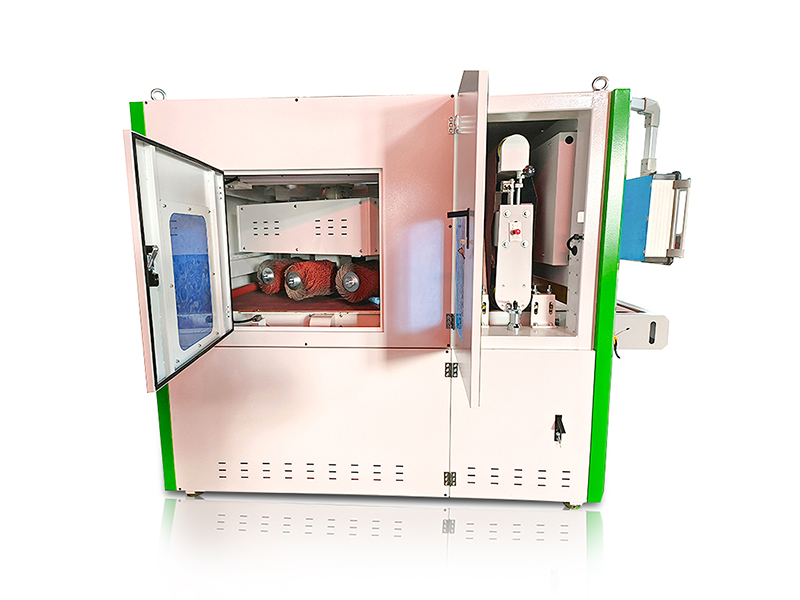

1. RW with 2/3 rows (2/3 groups per row) of universal roller brush structure, roller brush abrasive high-speed rotation, the surface of the workpiece to beat, so that the surface of the workpiece around the edge of the contour of the hole and smooth rounded, resulting in rounded corners.

2. For stamping, shearing, laser machine cutting, plasma cutting and other processes generated in the burr can be all-round one-time removal, so that all the edges of the workpiece, holes to achieve a small R arc effect, the processing process is safe, reliable, so that the workpiece to achieve the perfect effect.

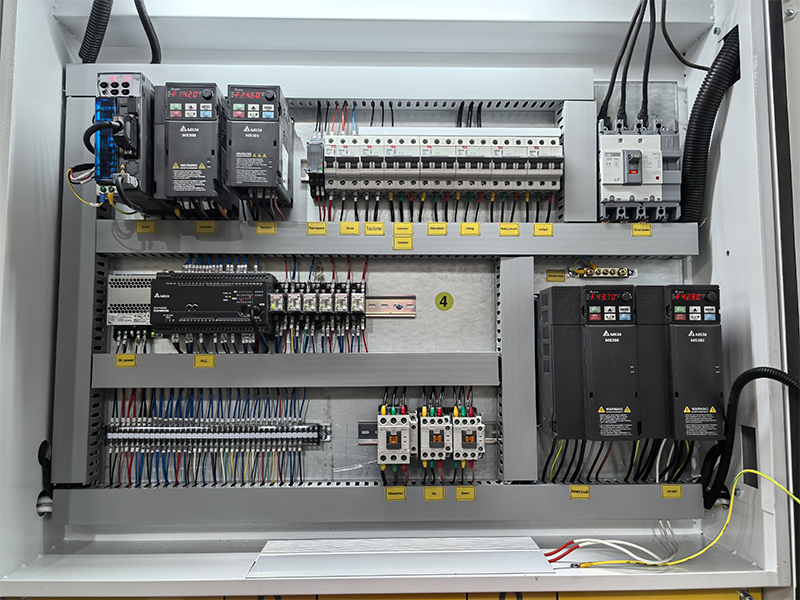

Why configure wet/dry dust collector?

Wet /dry dust removing method: the dust generated by the host in the work through the dust collection port effectively suck away most of the dust. Eliminate the potential danger of dust explosion and keep the inside of the equipment clean.

Metal parçalardan lazer oksidi çıkarmak neden önemlidir?

Oksijenle çalışan bir lazerle kesim yapılırken kesme kenarı boyunca lazer oksit oluşur. Parçaların kenarındaki bu lazer oksit, herhangi bir boya kaplamasının yapışmasını önleyecek ve kaynak işlemini çok daha zor hale getirecektir. Bu nedenle, kesme kenarları boyunca lazer oksitin giderilmesi, boyama ve kaynak gibi sonraki işlemleri büyük ölçüde iyileştirecektir.

Neden döner fırçalar ile yuvarlak sac kenar?

Thanks to the rotary brushes of the ADV® 508RW, uniform edge rounding for sheet metal can be achieved in a single pass. These rotary brushes can achieve an edge rounding result of up to R(0.1-1.0) all edges for a wide variety of metal alloys.

Daha Fazla Ürün

Automated Deburring Machines for laser cut, plasma cut, oxyfuel cut and punched parts. Deburr, edge round, deslag and finish your metal parts with high quality and efficiency

Automatic Deburring & Polishing - removes slag, oxidized skin, large flanging and other burrs.Hairline long straight wire for decorative purposes and Stainless steel sheet metal .

automated multifunction deburring polishing machines, so you can streamline your production process and improve output quality. high flexibility, consistent process reliability and high part quality