![]() 24h customer hotline +86 15395181370

24h customer hotline +86 15395181370

ADV® 118 Series Metal Flat Surface Polishing

Ürün Detayları

Metal Flat Sheet Polishing and Square Tube Pipe Polishing

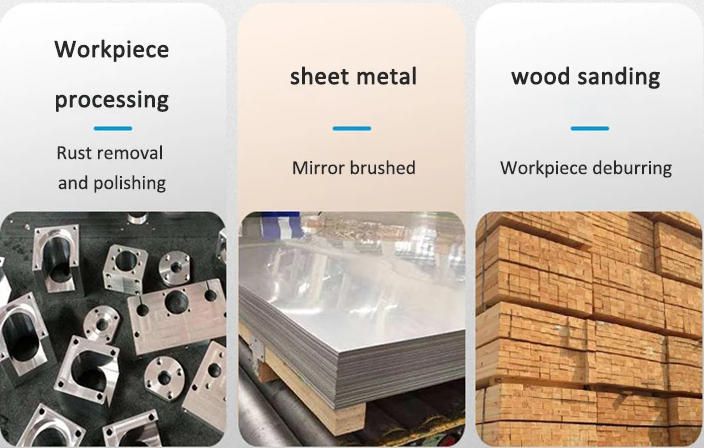

- Flat Metal Surface Polishing Machine Suitable for workpiece deburring, polishing and rust removalpaint removal, workpiece processing, etc.

- Small Metal Plane Polishing and Sanding Machine Automatic Desktop Flat Polishing Machine Deburring Rust Removal Belt Sanding,Consumables used sand belt and flap wheel.

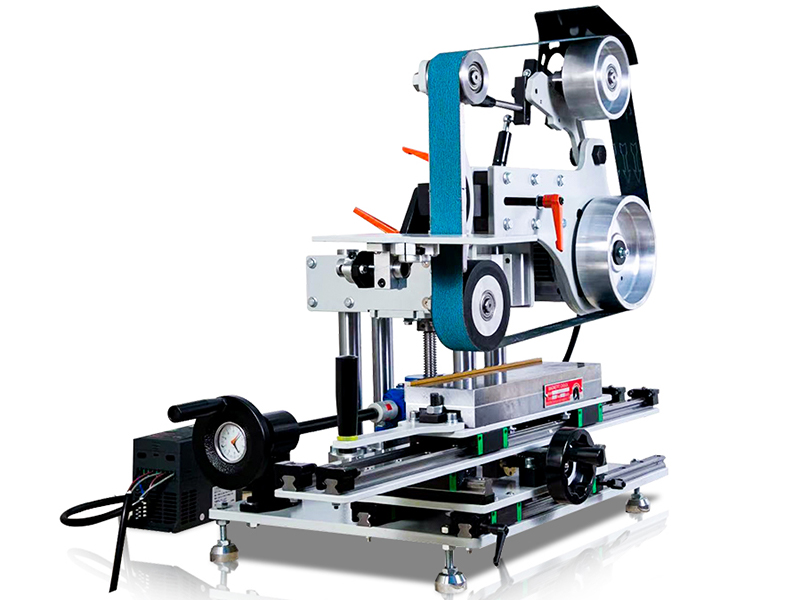

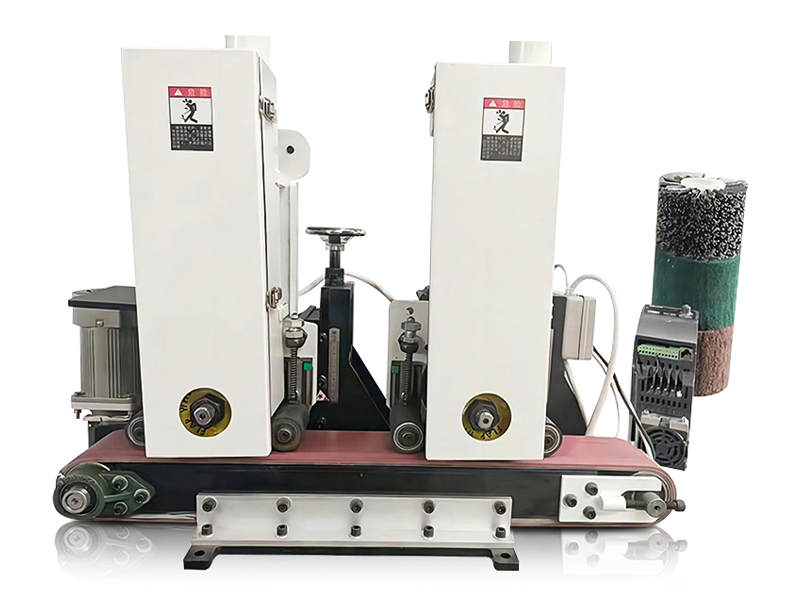

ADV 118-1 single grinding head machine

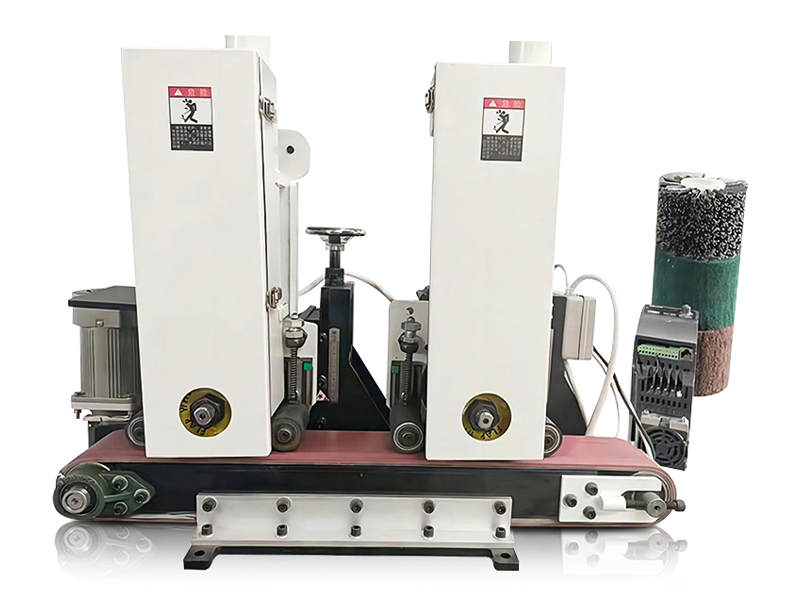

ADV 118-2 double grinding head machine

Hand Polish Machine for Stainless Steel Flat Sheet Metal Surface Polishing Machine :

Makine Parametreleri :

| Hayır | Öğe | Şartname |

| 1 | Model | ADV 118-1 / 118-2 |

| 2 | Ürün adı | ADV 118-1 / 118/2 flat sheet polishing brushing machine |

| 3 | Main motor | 2.2 kw |

| 4 | conveyor motor | 0.13 kw |

| 5 | conveyor width | 100 mm |

| 6 | conveyor speed | 15 m/min |

| 7 | Main motor speed | 2800 r/min |

| 8 | Belt size | 920*100 mm |

| 9 | machine size | 900*580*680 mm |

| 10 | Machine weight | 100 kg |

The Video Of the metal flat sheet polishing for Square Tube Pipes :

- Suitable for deburring, brushing and polishing of small flat metal sheets, square tubes and small parts

- Desktop level: small size, light weight, low noise, suitable for studio/home scenes

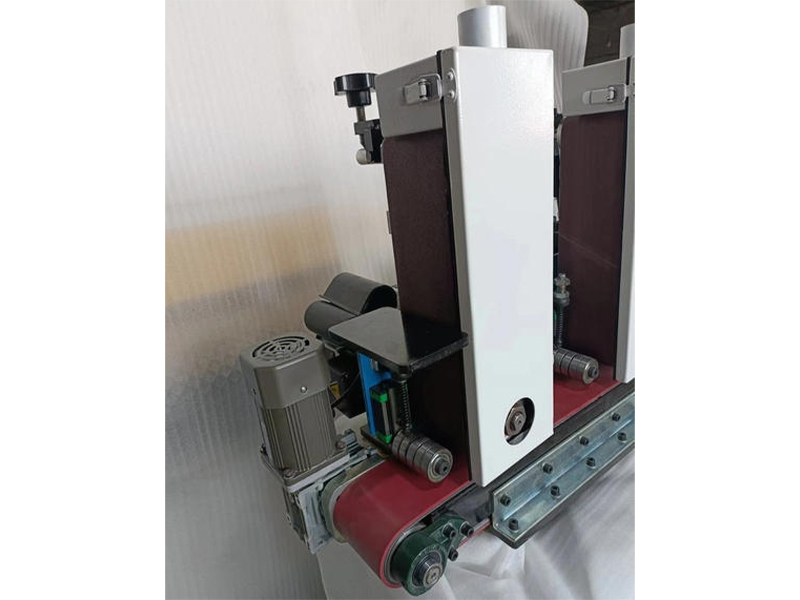

- Compatible with abrasive belts and polishing wheels, consumables can be easily replaced

- Equipped with fixtures or special conveyor belts to easily handle parts with smaller workpiece sizes

- Supports multi-station design and can be equipped with a dust collector

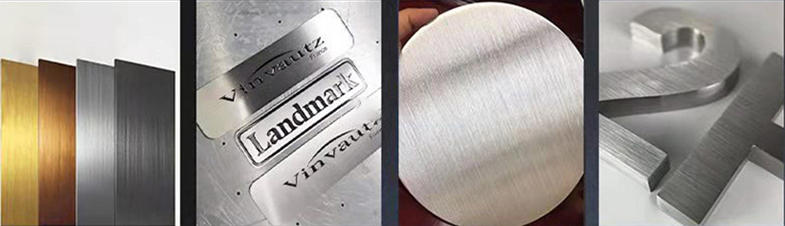

Metal Flat Sheet Polishing – No.4, hairline finish:

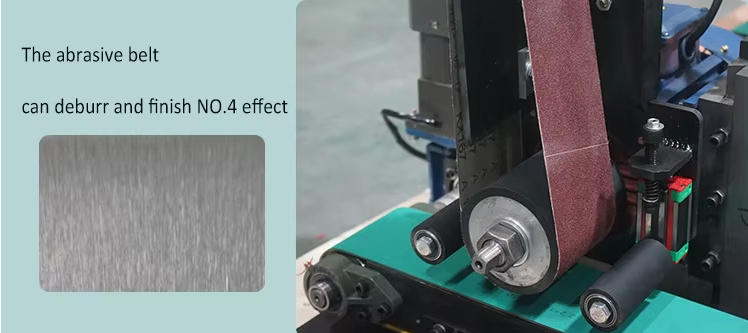

1.with sand belt to sweep the scratch line and sand-holes on the surface of the work piece(No.4 finish)

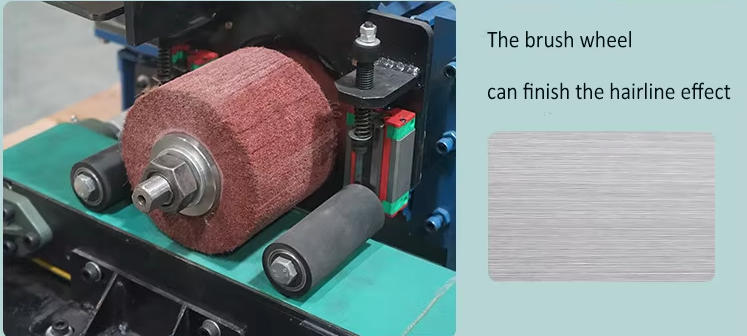

2.with the nylon wheel to get brushed effect. (hairline finish)

Finished product :

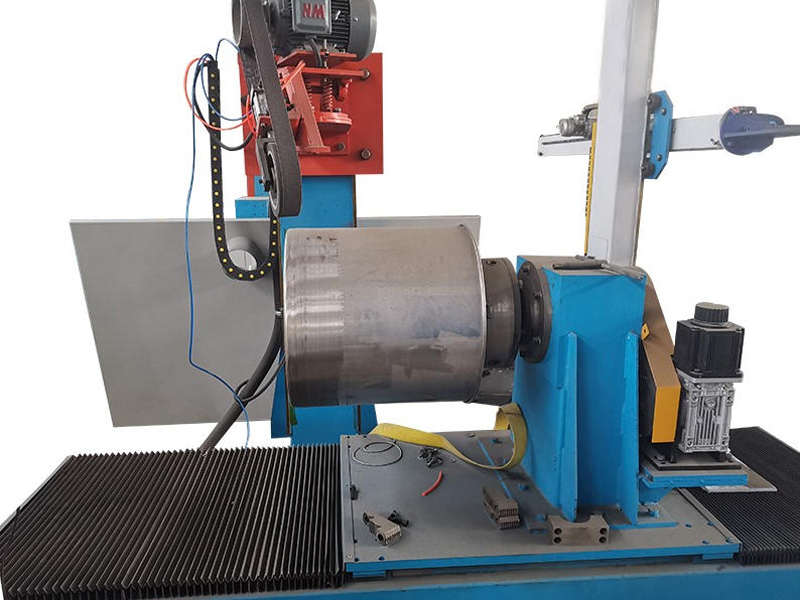

WIDE RANGE OF APPLICATIONS :

Why Choose Metal Flat Sheet Polishing

The advantages of the machine:

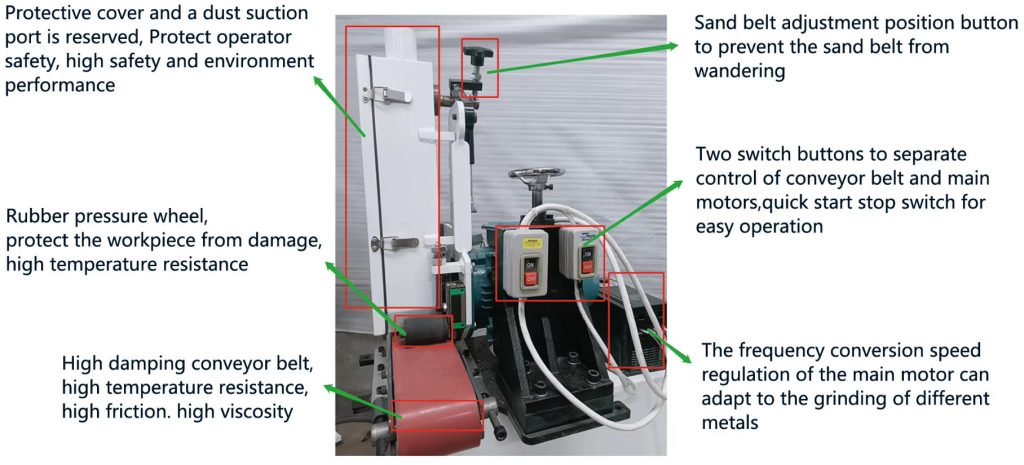

1.The scotch brite wheel and sand belt can be used together

2.Protective cover and a dust section port is reserved,protect operator safety,high safety and environmental performance. 3.Rubber pressure wheel, protect workpiece from damage, high temperature resistance.

4.The high damping conveyor belt is resistant to high temperature, high friction and high viscosity to achieve better grinding effect.

5.Two switch buttons to separate control of of conveyor belt and main motors,quick start stop switch for easy operation and more safety.

6.The height of the grinding table is adjustable and can be used for workpieces of different thicknesses.

7.The machine is equipped with a frequency converter, which can be adjusted according to the thickness and size of the workpiece to control the grinding speed.