![]() 24h customer hotline +86 15395181370

24h customer hotline +86 15395181370

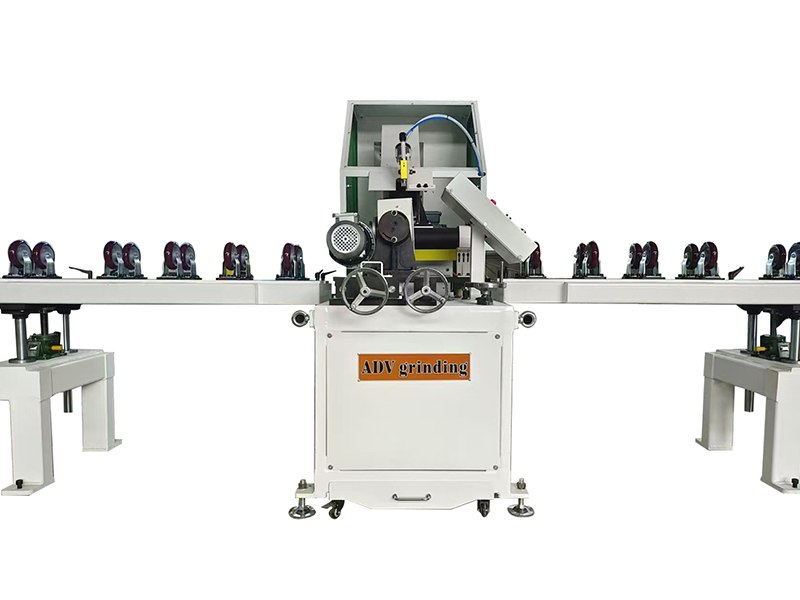

ADV® 108-6 Tüp Boru Parlatıcı

Ürün Detayları

Round tube polishing – Quality and productivity: straight tube(Long or Short), multi-station wet or dry finishing

Max 5- 100mm

Straight tubes

Optional 1 up to 10 stations

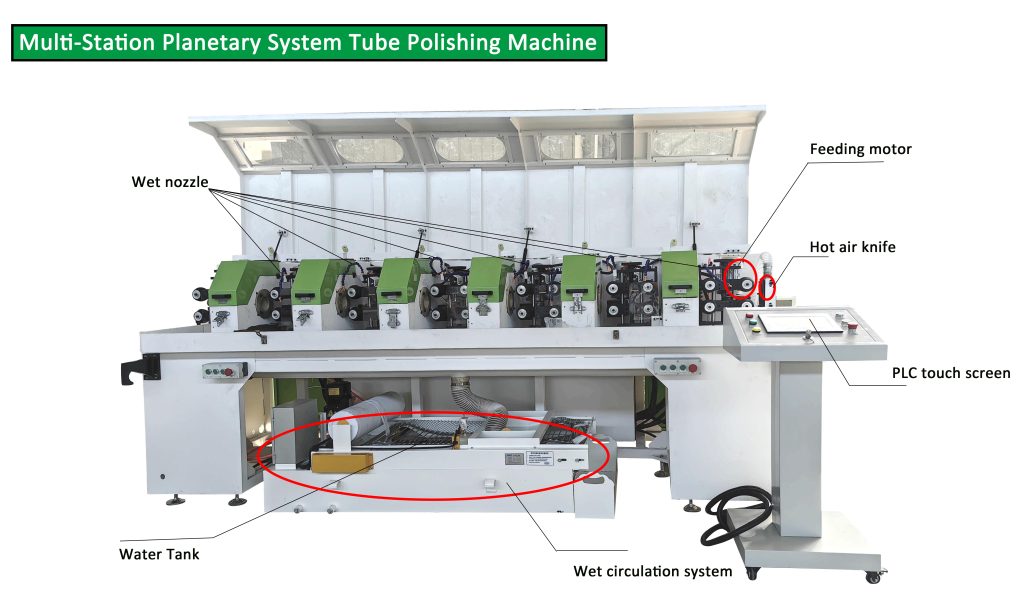

The ADV 108-6 round tube, multi-station wet finishing machine, available with 1 stations (ADV 108-1 TUBE POLISHER) and 6 stations (ADV 108-6 TUBE POLISHER), is equipped with the ADV planetary system and enables a faster finishing job than single–station machines.

Automatic work set-up and control of all the information about the tube finishing are done in a mobile panel with an integrated touchscreen. Completely independent finishing stations. Final finish in only one go.

The wet-operation system enables faster cooling of the tube as well as the possibility of working different types of metal simultaneously.

Machine parameters:

| Hayır | Öğe | Şartname |

| 1 | Model | ADV 108-6 |

| 2 | Available diameter | 5-100 mm |

| 3 | Toplam motor gücü | 26 kw |

| 4 | Abrasive belt motor power | 2.2 kw*6 |

| 5 | Speed of abrasive belt | 7.8-18 m/s |

| 6 | Rotary brush motor power | 1.5 kw*6 |

| 7 | Feeding system motor power | 0.37 kw*7 |

| 8 | Speed of feeding | 0.7-4 m/min |

| 9 | Size of abrasive belt | 940*50 mm |

The video of the 108-6 tube polishing machine

- To reduce temperature and prevent dust in the grinding area, a closed-circuit water-cooling system is employed. Water is sprayed onto the finishing area, filtered, and then pumped back into the machine. Also you can select dry tube polishing by your needs.

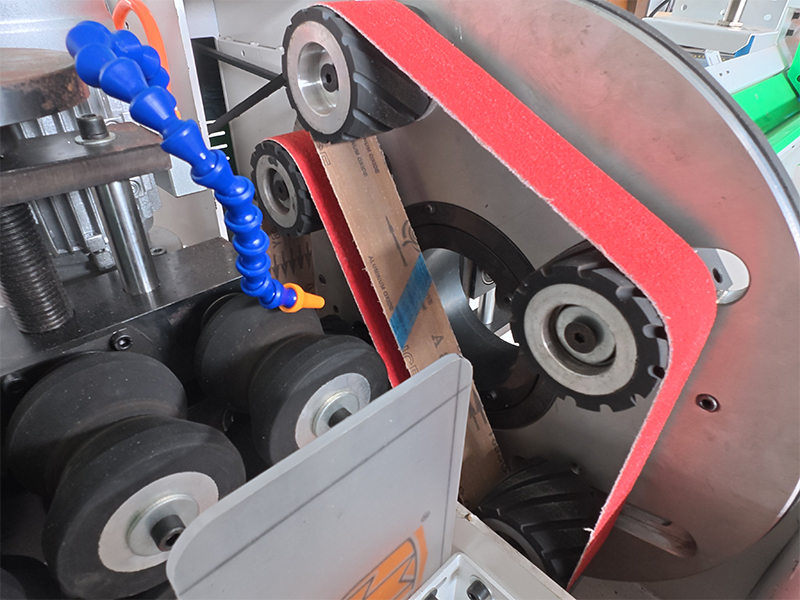

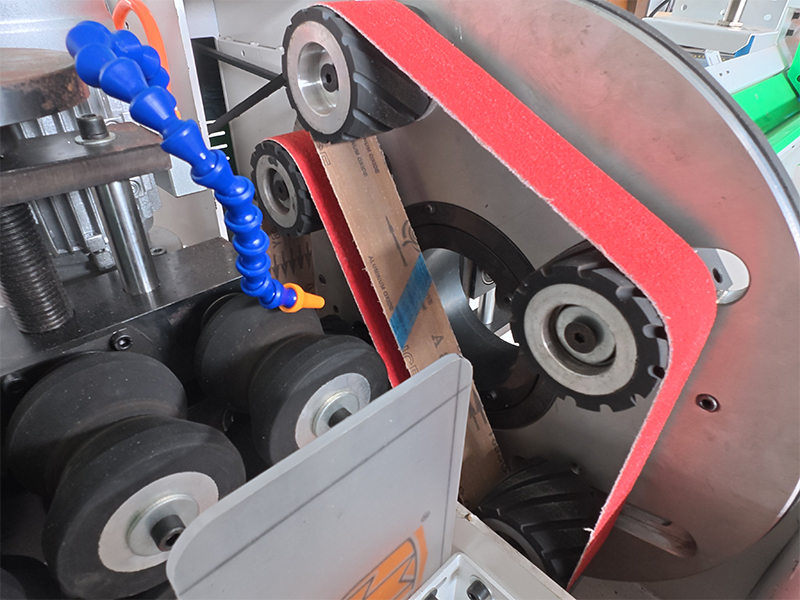

- With the 108 Planetary System the tube is not spinning. The abrasive belts rotate around the tube while it is safely transported by the feeding systems.

- The 108-6 is designed to work under intensive conditions, even multiple shifts a day, consistently delivering a multi-grain finish tube after tube.

- It is possible to equip the 108-N with tables for easier tube loading, unloading and storage.

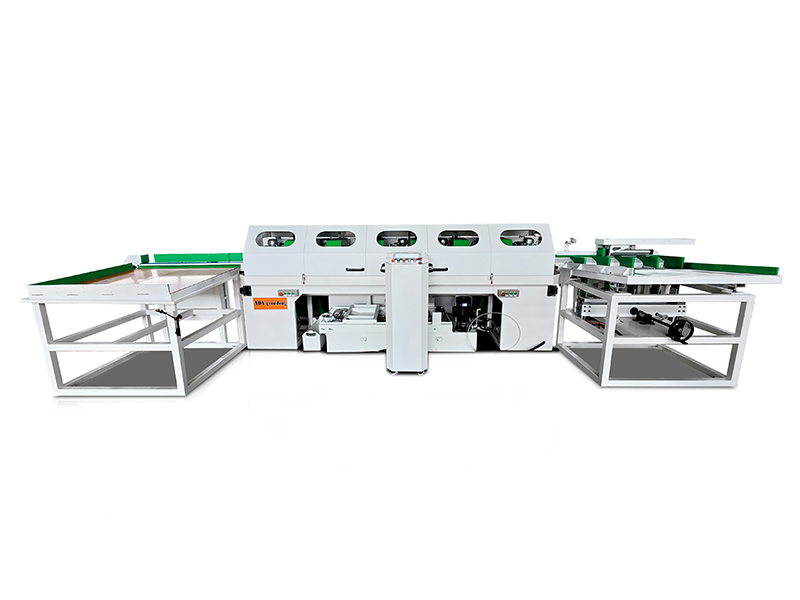

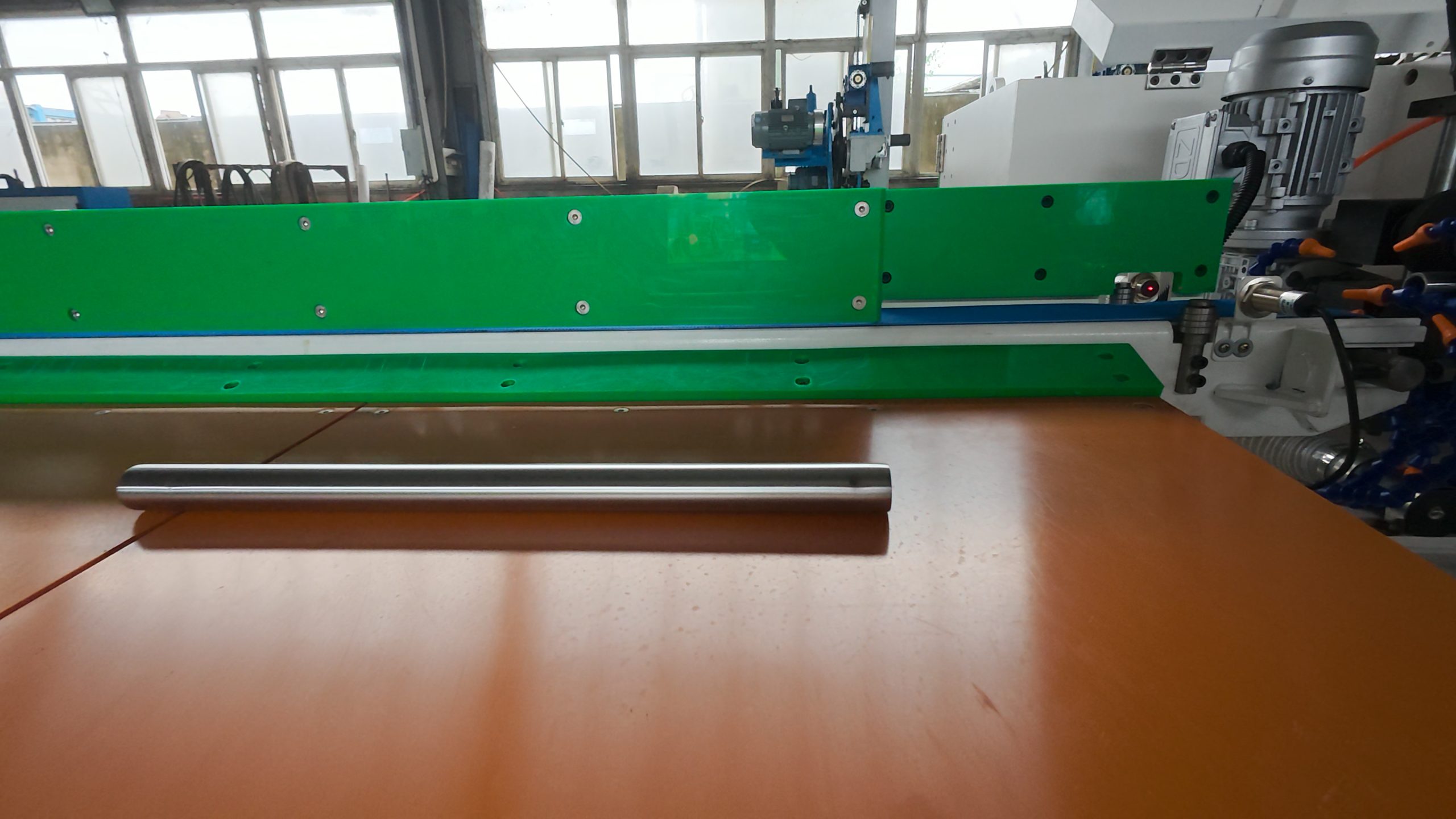

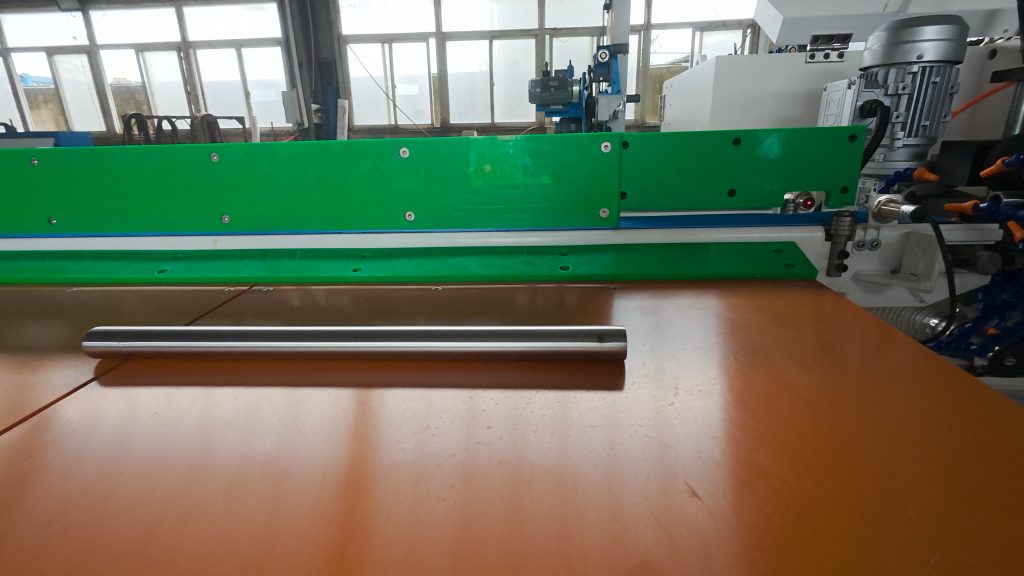

Tube Finished – work platform 1 :

Tube Finished – work platform 2 :

Daha Fazla Ürün

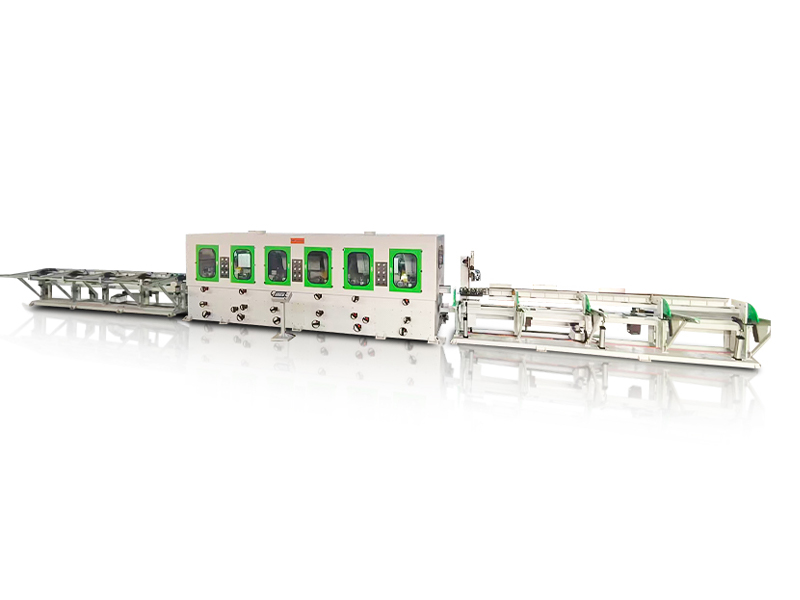

106 boru parlatma makinesi, farklı gereksinimlere göre 1-10 set taşlama kafası ile donatılabilir, planet sistemi ile donatılmıştır ve tek istasyonlu makinelere göre daha hızlı bir son işlem sağlar.

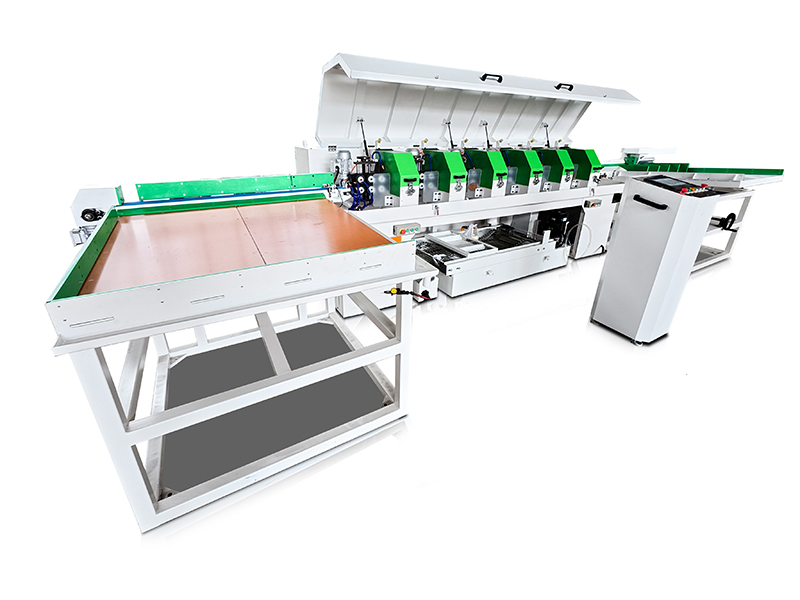

ADV 108-1 Yuvarlak Boru Parlatıcı, düz ve kavisli boruların yüzey parlatılması ve fırçalanması için en iyi seçimdir.

106-N - Farklı ızgaralara sahip aşındırıcı bantlar veya taşlama taşları kullanılarak borunun yüzey pürüzlülüğü azaltılabilir. Aynı zamanda, ayna, fırçalanmış ve diğer yüzey işlemlerini elde etmek için farklı parlatma taşları donatılabilir.