![]() สายด่วนลูกค้า 24 ชั่วโมง +86 15395181370

สายด่วนลูกค้า 24 ชั่วโมง +86 15395181370

ผลิตภัณฑ์

ADV Machinery ของ เครื่องลบคม & อุปกรณ์นำเสนอการประมวลผลขอบที่มีประสิทธิภาพและเชื่อถือได้สำหรับชิ้นส่วนที่เจาะด้วยเลเซอร์, พลาสมา, และเปลวไฟ ติดต่อเรา! ในฐานะผู้นำด้านเทคโนโลยีและตลาดในเทคโนโลยีการปรับระดับ เรานำเสนอเครื่องปรับระดับลูกกลิ้งที่มีความแม่นยำสูงหลากหลายที่สุดในโลก เราจะช่วยคุณในการเจาะ, การตัด, การลบคม, การปรับระดับ, การดัด, การเชื่อม, และการแทรกสำหรับแผ่นโลหะ

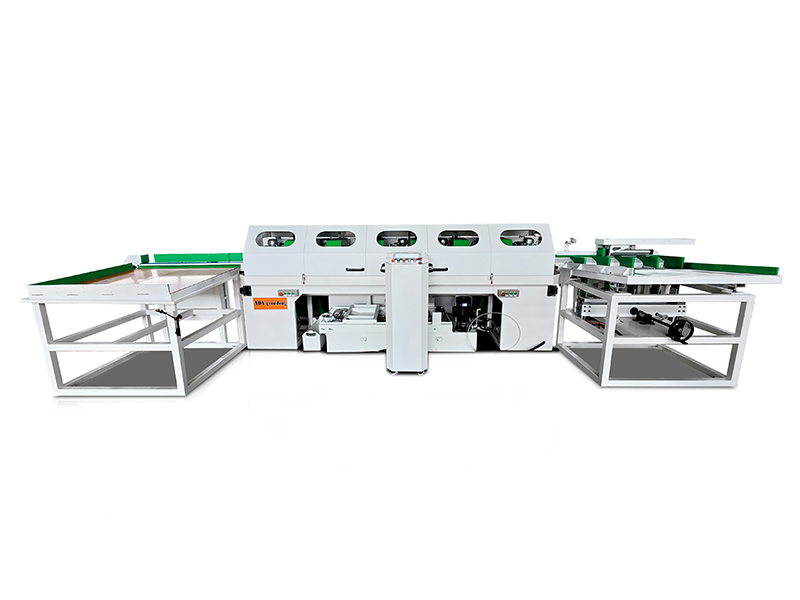

เครื่องกำจัดครีบและเครื่องตัดขอบมน (ปรับแต่งเครื่องตามข้อกำหนดต่างๆ ตามความต้องการ)

กระบวนการลบคมเกี่ยวข้องกับการกำจัดคมหรือเศษโลหะที่หลงเหลืออยู่เพื่อให้พื้นผิวเรียบและปราศจากขอบคม สิ่งนี้มีความสำคัญเพื่อป้องกันไม่ให้คมหรือเศษโลหะก่อให้เกิดอันตรายต่อผู้ที่ทำงานกับวัสดุ และเพื่อปรับปรุงคุณภาพและประสิทธิภาพการทำงานของชิ้นส่วนที่ผ่านการแปรรูป

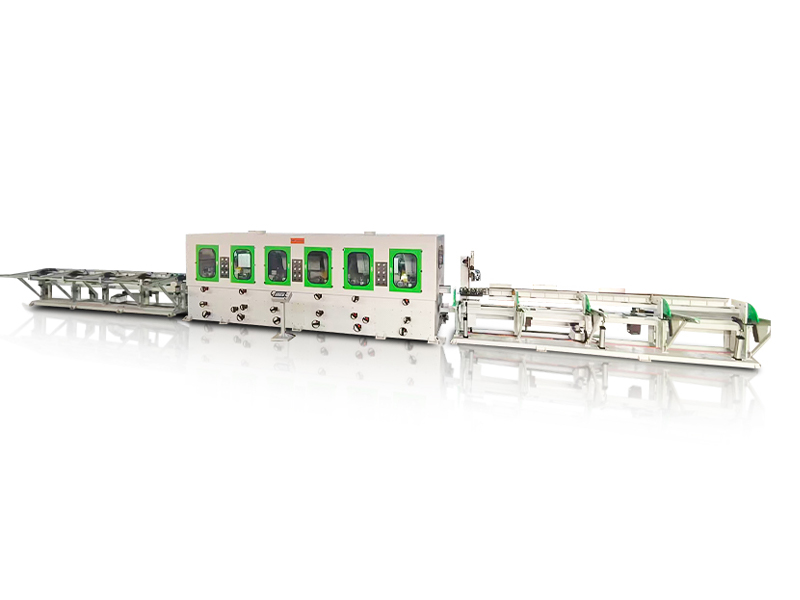

เครื่องปรับระดับที่รับประกันความเรียบสม่ำเสมอสำหรับแผ่นโลหะทุกแผ่นและแผ่นหนักทุกแผ่น

เราให้บริการเครื่องปรับระดับประสิทธิภาพสูงอย่างครบวงจร: ตั้งแต่เครื่องปรับระดับความแม่นยำสูงสำหรับชิ้นส่วนโลหะ แผ่น และแผ่นเหล็ก ไปจนถึงเครื่องปรับระดับความโค้งของขดลวดประสิทธิภาพสูงที่สามารถประมวลผลวัสดุ AHSS ได้ เครื่องปรับระดับแผ่นโลหะและชิ้นส่วนของเรา มีความแม่นยำสูงมาก และให้ผลลัพธ์ที่ยอดเยี่ยมอย่างสม่ำเสมอ พวกมันมอบคุณค่าเพิ่มมหาศาลโดยช่วยประหยัดเวลาและลดของเสียจากการผลิตซ้ำ รวมถึงเวลาที่สูญเสียไปในการแก้ไขงาน ให้คุณได้ใช้ประโยชน์จากเทคโนโลยีการปรับระดับที่ทันสมัยของเรา

เครื่องขัดแผ่นโลหะจาก ADV Machinery เครื่องนี้ใช้สำหรับขัดเงาเหล็กinox, แผ่นอลูมิเนียม, แผ่นโลหะ และผิวเรียบต่าง ๆ เป็นต้น ติดต่อเราวันนี้!

เครื่องขัดเงาโลหะ เป็นอุปกรณ์ที่จำเป็นในโรงงานและโรงงานอุตสาหกรรม ออกแบบมาเพื่อเปลี่ยนพื้นผิวโลหะจากสภาพหยาบหรือหมองให้กลายเป็นผิวเงาสูงและละเอียด ผลิตภัณฑ์มีหลากหลายรูปแบบ ตอบสนองความต้องการที่หลากหลาย

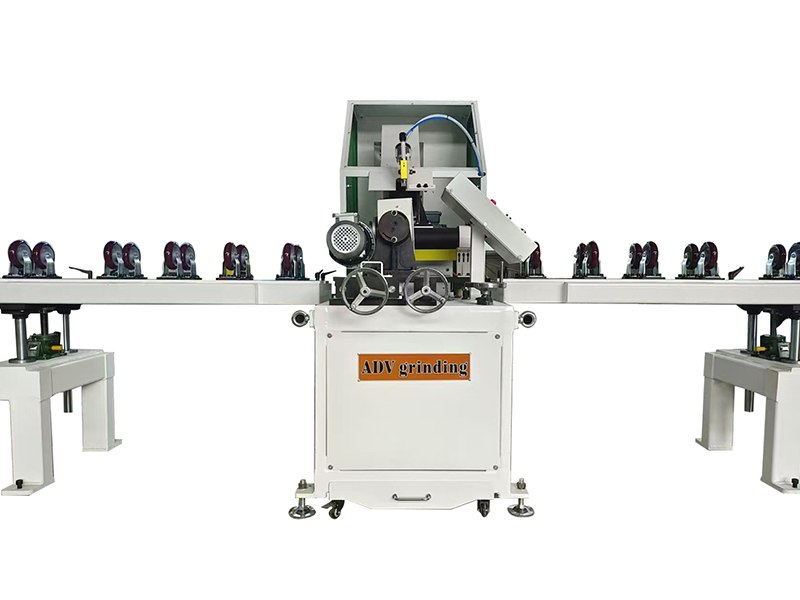

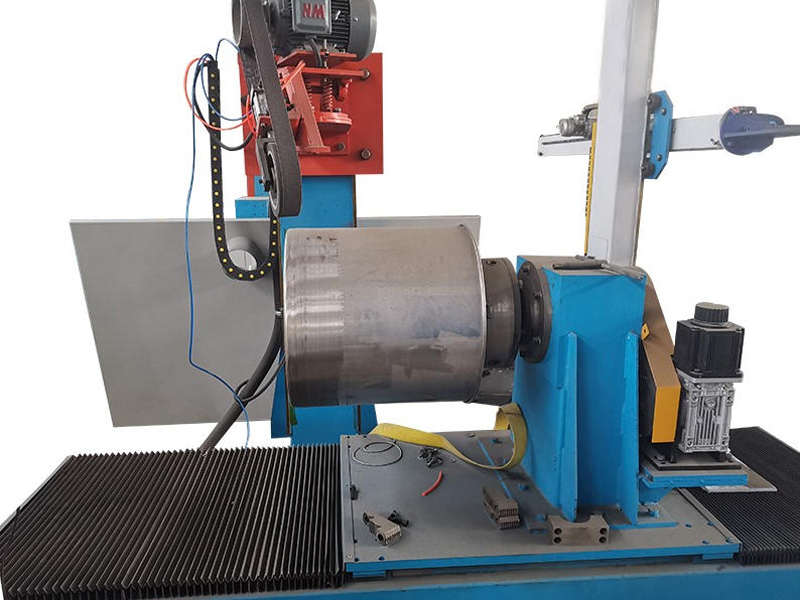

เครื่องจักรสำหรับตกแต่งผิวโลหะสำหรับท่อกลม/ท่อกลม. ความจุตั้งแต่ 5 มิลลิเมตร ถึง 310 มิลลิเมตร.

กระบวนการขัดเงาด้วย ดาวเคราะห์ ล้อ,ไร้ศูนย์กลาง ล้อและ สายพานขัด.

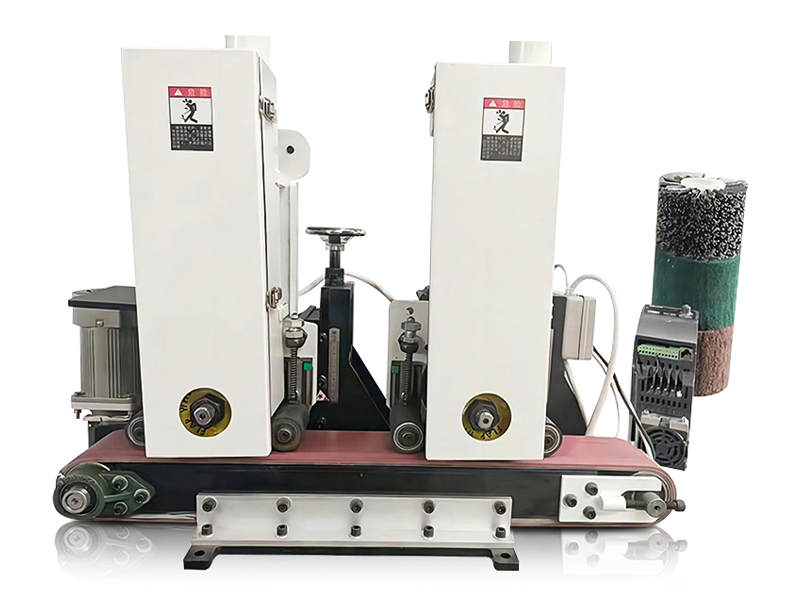

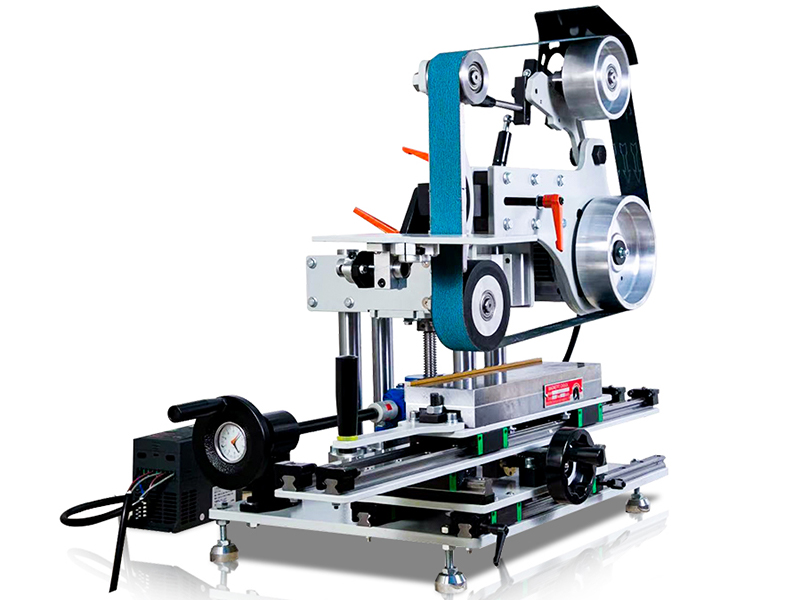

สากล เครื่องเจียรสายพาน พร้อมอุปกรณ์มาตรฐานครบครัน และความสามารถในการทำงานได้ทั้งแนวตั้งและแนวนอน

- เปลี่ยนสายพานขัดได้อย่างรวดเร็วและง่ายดาย

- การตั้งค่ามุมเจียรที่ง่ายและรวดเร็ว

- การเปลี่ยนตำแหน่งศีรษะอย่างรวดเร็วในช่วงแนวตั้ง-แนวนอน

เหมาะสำหรับการขัดหัวมาตรฐานต่างๆ, ขัดหัวทรงกรวย, ขัดหัวทรงกลม, ขัดหัวลูกบอล, ขัดหัวแรงดันอุตสาหกรรม, ขัดหัวที่เกิดการเสียรูป, ขัดหัวสแตนเลสทรงรี และขัดผิวด้านในและด้านนอกของหัวซีลสแตนเลส. เครื่องขัดหัวจาน ใช้กันอย่างแพร่หลายในการขัดชิ้นงานในด้านการแพทย์ อุตสาหกรรมเคมี การฟอกอากาศ อาหารและเครื่องดื่ม การกรองน้ำ เป็นต้น

- การใช้งานที่ง่ายและปลอดภัย

- การออกแบบที่ได้เปรียบ

- ควบคุมได้เกือบอัตโนมัติทั้งหมด

- การกระจายความร้อนที่ดีและมีปริมาณแคลอรีเท่ากัน

- ทนทานและเชื่อถือได้