![]() 24h customer hotline +86 15395181370

24h customer hotline +86 15395181370

ADV® 508-RR

Detalhes do produto

Metal Deburring Machine – Wide belt & Wide belt(2 blet grinidng machine to deburr after laser cutting)

1. For deburring, sanding, and finishing of flat metal sheets (aluminum, copper, stainless steel, etc.).

2. For removing longitudinal burrs from laser-cut, stamping, and water jet-cut workpieces.

3. Standard available widths are 300mm, 630mm, 800mm, 1000mm, 1300mm, 1600mm or customized.

4. The metal finishing machine can be used for wet or dry processes.

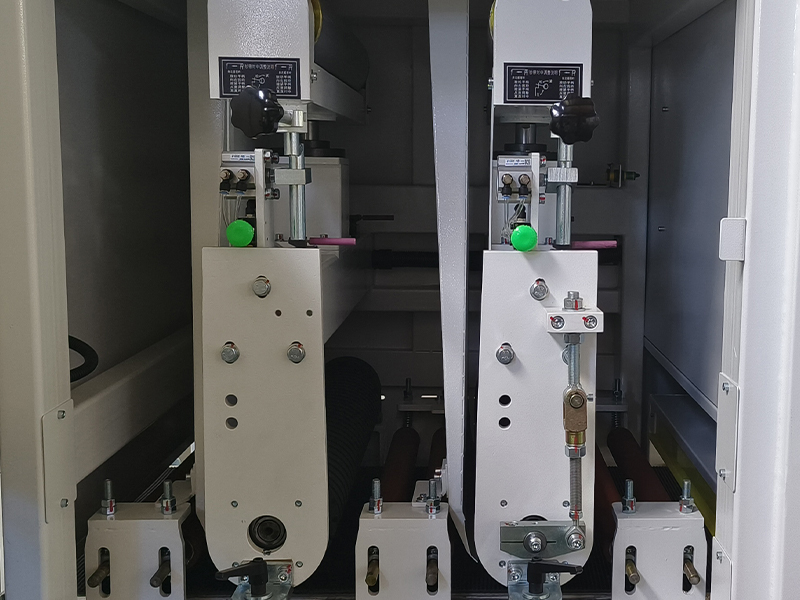

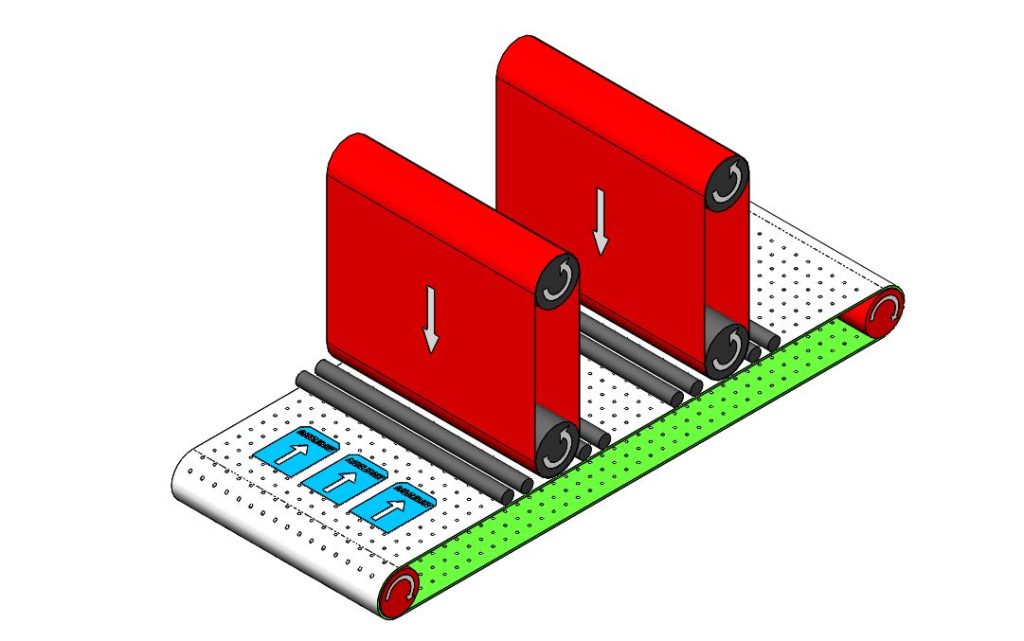

- The ADV® RR Deburring Machine with 2 sets of sanding belt(1# sanding belt removes heavy slag, oxidized skin, large flanging and other burrs on the surface of the workpiece.2# sanding belt brushes and finish the surface of the workpiece.)

- The ADV 508 RR removes slag particles, heavy flanges and other large burrs on the surface of the workpiece by two sets of wide wide belt mechanisms, and passes through the type of processing without destroying the dimensional accuracy of the workpiece.

- This equipment adopts high temperature resistant conveyor belt to transfer the workpiece, frequency conversion speed regulation.

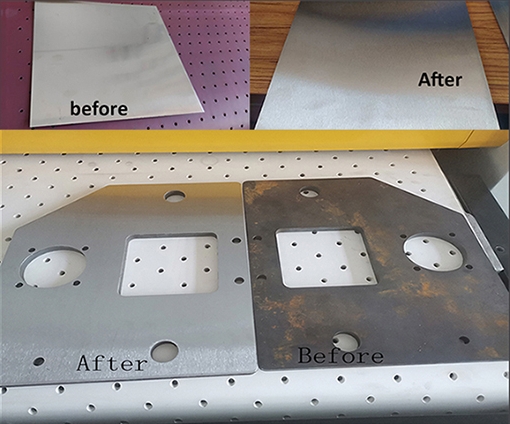

Before and after Deburring & Finishing :

- O ADV® RR deburring machine optimally prepares your punched parts or laser cut parts for further processing. All burrs are removed, if desired, you can also apply a special surface finish.

- 508-RR Finishing Machine is an economical metal sanding finishing machine that can handle scratch repair and descaling of various metal sheets to obtain good surface consistency, replacing inefficient manual grinding.

- Wet dust collectors or water filtration systems are available at request

Finishing of metal sheet parts refers to the process of rounding and refining the surfaces of metal sheet parts to give them a smooth, aesthetically appealing appearance. This process typically involves removing imperfections, burrs, rough edges, and other undesirable features from the surface.

DEBURRING | Oxide Removal | Surface Finish

O objetivo do acabamento é melhorar a qualidade e o aspeto visual das peças de chapa metálica, contribuindo também para a sua proteção. Garante um acabamento uniforme e pode ajudar a melhorar a aderência de revestimentos, tintas ou outros materiais na superfície.

See for yourself: the Video of the ADV® RR Wet or Dry Metal Deburring Machine!

Frequently Asked Questions

Porque é que é importante remover o óxido a laser das peças metálicas?

- O óxido laser é criado ao longo da aresta de corte quando se corta com um laser alimentado a oxigénio. Este óxido laser ao longo do lado das peças impedirá a aderência de qualquer revestimento de tinta e tornará a soldadura muito mais difícil. Por conseguinte, a remoção do óxido laser ao longo das arestas de corte melhorará consideravelmente os processos a jusante, como a pintura e a soldadura.

Can deburring,oxide removal and surface finishing be done by a single machine orprocess?

- Yes,deburring,oxide removal,and surface finishing can all be done by a single machine.508 RR has two groups of dry abrasive belt with 2-stage machine is single-sided and can evenprocess sheet metalparts as small as 0.3×0.3mm.This is a professional deburring machine, whether you have thin or thick workpieces

What materials are suitable for 508 RR metal automatic deburring?

- The RR máquina de rebarbar can process a wide array of metal alloys.These alloys include steel,aluminum,brass,copper,titanium,stainlesssteel and even specialty alloys.

Mais produtos

3 blet grinidng machine to deburr after laser cutting.The purpose of finishing is to enhance the quality and visual appeal of the metal sheet parts while also contributing to their protection. It ensures a uniform finish and can assist in improving the adhesion of coatings, paint, or other materials on the surface.

Rr Máquina de acabamento de metal para escovar e polir.O acabamento de peças de chapa metálica refere-se ao processo de arredondamento e refinamento das superfícies das peças de chapa para dar-lhes uma aparência suave e esteticamente atraente.