![]() 24h customer hotline +86 15395181370

24h customer hotline +86 15395181370

제품 세부 정보

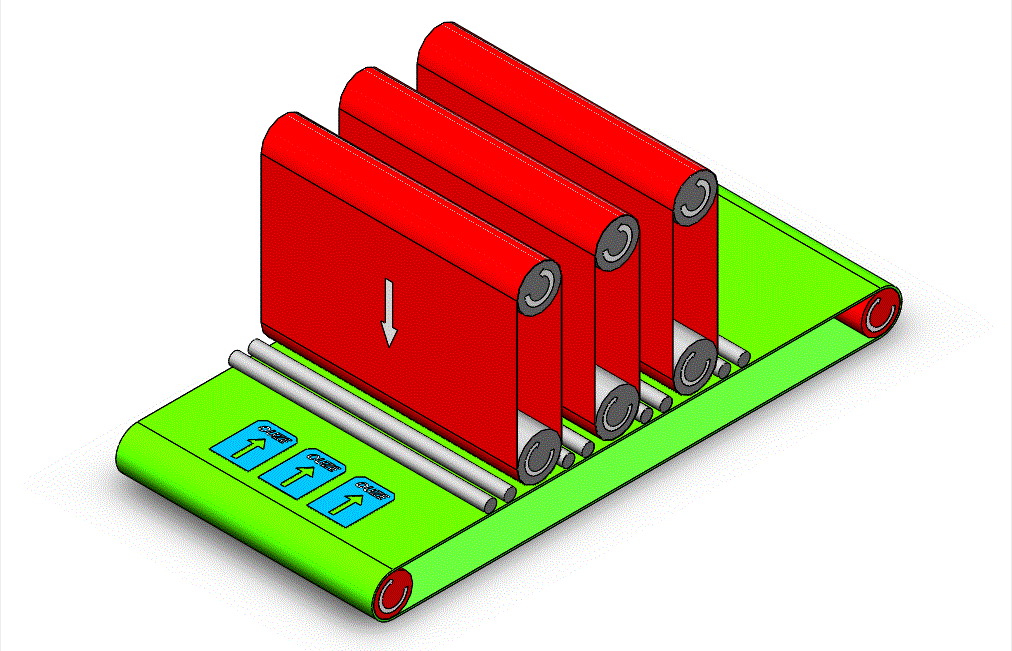

Wet or Dry Deburring and Finishing Machine – Wide Belt & Wide Belt & Wide Belt(3 blet grinidng machine to deburr after laser cutting)

- Effective processing width : 300/630/800/1000/1300/1600mm(11.8″/24.8″/31.5″/39.4″/51.2″/63″)

- Effective processing thickness: 0.5-100mm(0.02-3.9”)

- Conveying speed: 0.5-10m/min

- Minimum werkpiece size : 280mm

- Processing : Dry or wet

- Multi-station surace Roughness inspection : ≤0.1um

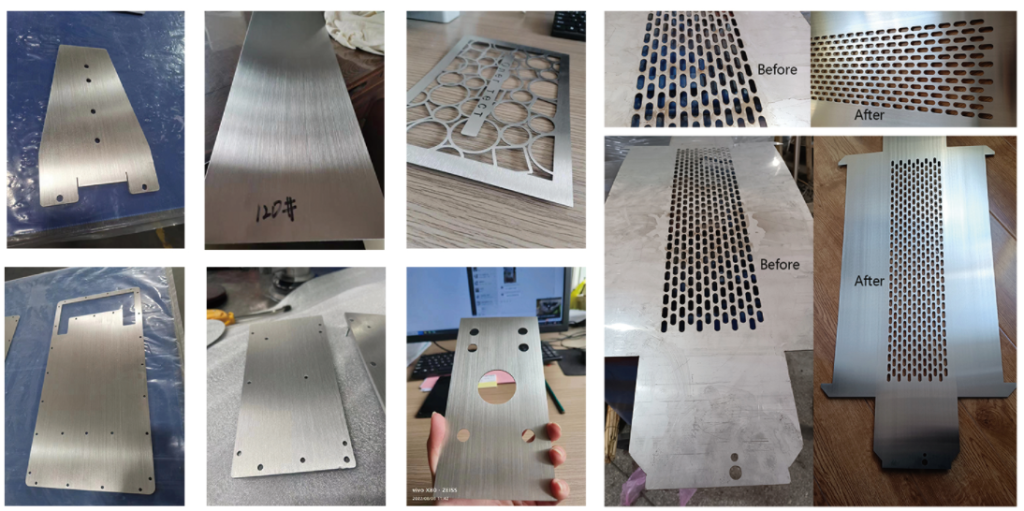

DEBURRING / Oxide Removal / Surface Finish

The ADV 508 RRR wet or dry deburring-Primarily designed for comprehensive surface treatment, this equipment performs metal finishing, laser oxide layer removal, polishing, and other processes. It effectively removes burrs, weld spots, and imperfections from operations like punching, shearing, and laser cutting in a single pass. This ensures safe, reliable processing, achieving a high-quality finish for workpieces.

Stainless steel , aluminum , carbon steel , coated workpiece , galvanized plate , copper plate

Why choose wet deburring?

The whole grinding process is carried out in a wet state, which effectively avoids deformation of the product due to overheating, and the grinding effect is good, safe and efficient.Choosing a wet deburring machine has several advantages, particularly for applications that involve heavy-duty or high-speed processing.

Wet deburring effectively reduces dust and airborne particles, enhancing workplace safety and air quality. The cooling effect of water also prevents overheating, making it suitable for heat-sensitive materials and maintaining consistency in abrasive performance.

Additionally, wet deburring often leaves a cleaner, smoother surface finish, especially for intricate or highly polished workpieces.

더 많은 제품

레이저 절단 후 디버링하는 2블렛 그리니딩 기계: ADV의 고급 마감 기계를 사용하면 금속판 부품에 다양한 마감 처리를 적용할 수 있습니다. 적절한 연마 벨트를 적절한 속도와 함께 사용하여 금속판 부품을 선형 마감 또는 무방향 마감 등 원하는 대로 마무리할 수 있습니다.

브러싱 및 연마 용 금속 마감 기계.금속 시트 부품의 마감은 시트 부품의 표면을 둥글게하고 다듬어 매끄럽고 미적으로 매력적인 모양을 만드는 과정을 말합니다. 표면에서 결함, 버, 거친 모서리 및 기타 바람직하지 않은 특징을 제거합니다.