![]() 24시간 고객 핫라인 +86 15395181370

24시간 고객 핫라인 +86 15395181370

자동 디버링 기계: 금속 제조의 효율성 및 정밀도 향상

Introduction

In modern metal fabrication, burrs and rough edges are more than just visual imperfections—they can compromise safety, interfere with assembly, and reduce coating adhesion. As production volumes and quality expectations rise, manual deburring struggles to keep pace. Automated deburring systems have emerged as the industry standard, offering unmatched speed, consistency, and reliability. This article explores how automated deburring transforms metalworking processes, enhances product quality, and supports sustainable manufacturing growth.

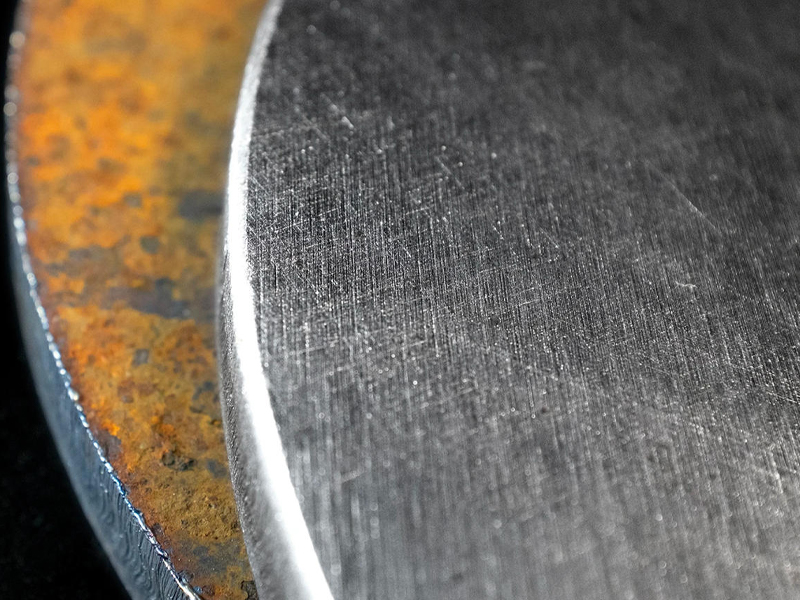

Why Burrs Matter: Beyond Surface Imperfections

Burrs are sharp, often microscopic projections formed during cutting, punching, or machining. Left untreated, they can:

- Cause injury during handling

- Lead to coating failure or uneven paint adhesion

- Create gaps in welded joints

- Increase wear on moving parts

Manual deburring relies heavily on operator skill, leading to inconsistencies, fatigue, and higher labor costs. Automated systems eliminate these variables, delivering uniform finishes across every part.

What Is Automated 디버링 머신?

Automated deburring uses motorized abrasive belts, brushes, or sanding heads to remove burrs and refine edges without manual intervention. Advanced systems—such as those from ADVANMETALTECH—incorporate intelligent features like:

- AbrasiveSync Automated Control: Maintains consistent abrasive performance

- Parameta Smart Recall: Stores and recalls process parameters for repeat runs

- ADV Conveyor Systems: Secures parts via vacuum or magnetic retention

- GuardianSense Maintenance: Monitors machine health in real time

Manual vs. Automated Deburring: A Clear Comparison

While manual deburring (e.g., M300 Series tools) is still used for prototyping or very low volumes, automated systems excel in production environments:

| Aspect | Manual Deburring | Automated Deburring |

|---|---|---|

| Speed | Slow, labor-intensive | Up to 10× faster throughput |

| Consistency | Variable, operator-dependent | Uniform across all parts |

| Labor Cost | High | Reduced by up to 30% |

| Safety | Higher risk of injury | Enclosed design, dust extraction |

Types of Automated Deburring Machines

Different applications call for specialized equipment:

- Wide-Belt Deburring Machines: Ideal for flat sheet metal and laser-cut panels

- Brush Deburring Machines: Effective for edge rounding and oxide removal

- Vibratory Finishing Machines: Suited for small or bulk components

- Integrated Systems (e.g., ADV RW Deburring Series): Combine deburring, edge rounding, and surface finishing in one process

Core Benefits of Automated Deburring

1. Increased Efficiency

Automated systems process multiple parts simultaneously, turning hours of manual work into minutes of machine runtime.

2. Enhanced Quality & Consistency

Every part receives identical treatment, improving weld quality, coating adhesion, and overall finish uniformity.

3. Reduced Operational Costs

Lower labor dependence, decreased scrap rates, and minimal rework contribute to significant cost savings.

4. Improved Workplace Safety

Enclosed designs, anti-pinch systems, and advanced dust extraction—such as ADV’s Wet Extraction System with 99% efficiency—create cleaner, safer environments.

5. Scalability

Automated deburring supports continuous, multi-shift operation without fatigue, enabling manufacturers to scale production seamlessly.

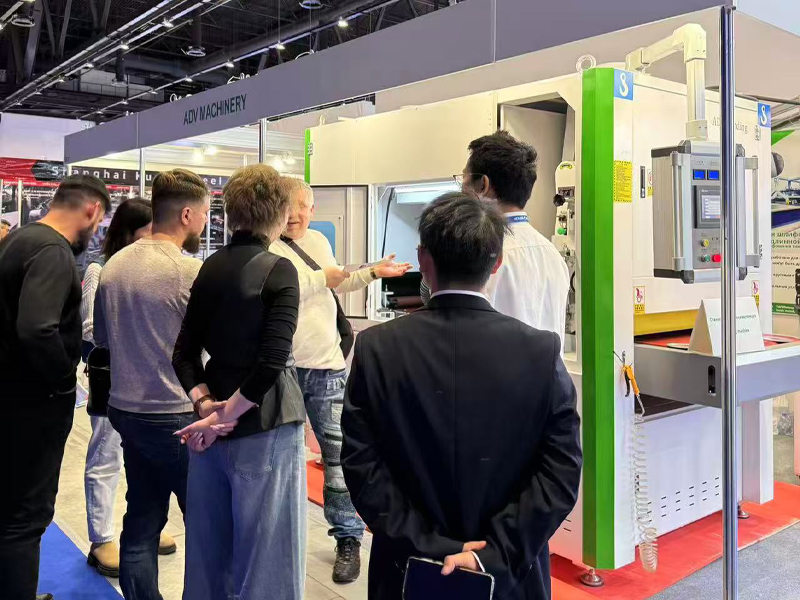

China’s Role in Advanced Deburring Technology

Chinese manufacturers like ADVANMETALTECH have transitioned from cost-driven production to innovation-led engineering. With robust R&D, intelligent software integration, and adherence to international standards, Chinese deburring machines now compete globally—offering high performance, reliability, and value.

FAQs About Automated Deburring

Q1: Which industries benefit most from automated deburring?

A: Automotive, aerospace, energy, electronics, and general metal fabrication—all industries requiring high-volume, precision edge finishing.

Q2: How does automated deburring improve workflow?

A: It enables continuous processing, reduces bottlenecks, and prepares surfaces immediately for coating or assembly.

Q3: Are Chinese-made deburring machines reliable?

A: Yes. Brands like ADVANMETALTECH produce globally certified machines backed by international service networks.

Q4: Can automation reduce production costs?

A: Absolutely. Studies show reductions of up to 30% in labor and energy costs while maintaining superior quality.

Q5: Does deburring affect welding or coating quality?

A: Yes—positively. Rounded edges improve paint adhesion and reduce stress concentrations in welds.

Conclusion

Automated deburring is no longer a luxury—it’s a necessity for competitive metal fabrication. By delivering consistent quality, enhancing safety, and reducing costs, systems like those from ADVANMETALTECH empower manufacturers to meet today’s demands while future-proofing their operations. Investing in automated deburring isn’t just about removing burrs—it’s about refining your entire production process for greater efficiency, reliability, and growth.

Keywords for Search Optimization

deburring machine for sheet metal, metal surface finishing machine, pipe polishing machine, tube polishing machine, industrial belt grinder, automated edge rounding, ADV deburring series, metal finishing automation, China deburring technology

더 많은 기사

- 뉴스, 기술

- 뉴스, 기술

- 전시회