![]() 24h customer hotline +86 15395181370

24h customer hotline +86 15395181370

제품 세부 정보

508-HR (Hammerhead & Wide sanding belt) 디버링 머신

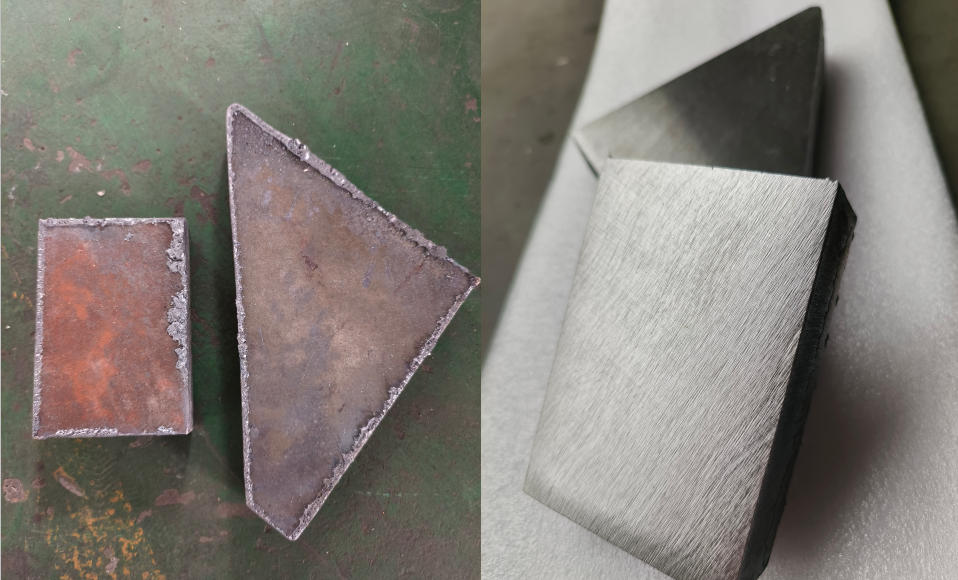

Hammerhead: The cleaning hammer rotates at high speed, knocks on the workpiece surface, cleans the workpiece surface and surrounding contours, and removes slag from the edge of the metal plate

Wide belt: Deburring and rust removal of large areas of metal parts surfaces

- 508 HR Series – The manual removal of slag is time-consuming and burdensome for both the operator and the machines, leading to high costs and wear. The HR, specifically developed by ADV, automatically remove slag after plasma or oxy-fuel cutting. These machines can be easily integrated into any production line, removing slag before the product reaches the deburring machine for edge rounding.

- The removed waste material is collected in a bin and can be disposed of as scrap. By performing slag removal separately, contamination in the deburring machine is prevented.

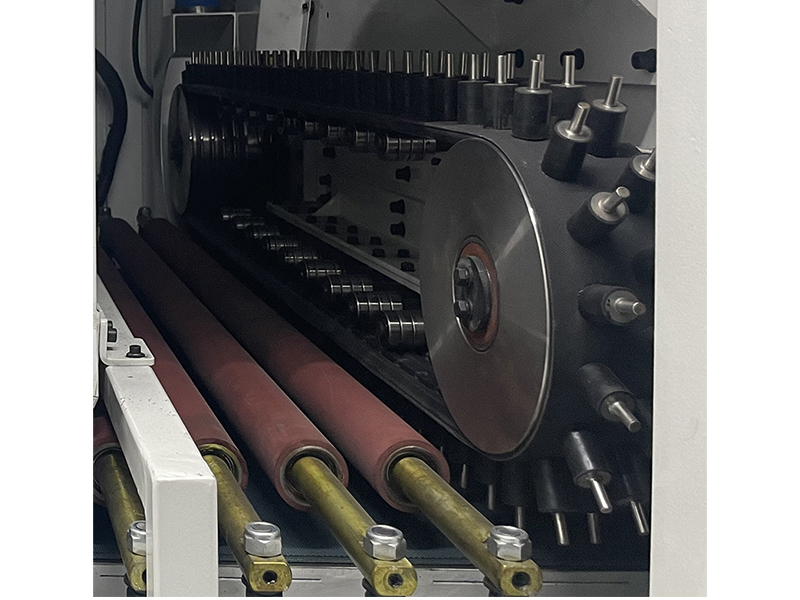

- Both models are ergonomically designed with a touchscreen control for ease of use. The slag is effectively removed by two counter-rotating slag breaker rollers, which strike the product twice per revolution. The result is a flat product ready for further finishing.

Effective processing width:

300/630/800/1000/1300/1600mm(11.8″/24.8″/31.5″/39.4″/51.2″/63″)Effective processing thickness:

0.5-100mm(0.02-3.9″)conveying speed:

0.5-7m/minMinimum workpiece size:

5050 mm(Vacuum)3030 mm(Magnetic)

Hammer set service life:

6-12 monthsslag removal height:

5mm(0.2”)

The video of the 508 HR Deburring Machine:

ergonomically designed with a touchscreen control for ease of use. The slag is effectively removed by two counter-rotating slag breaker rollers, which strike the product twice per revolution. The result is a flat product ready for further finishing.