Share quotes, track production milestones, level-up team benefits together.

Planetary System Polishing

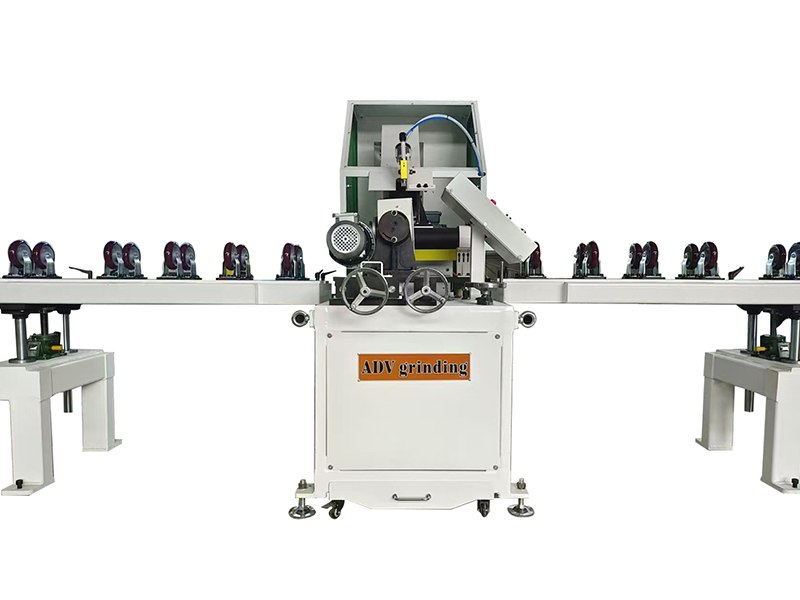

- Centerless System Polishing

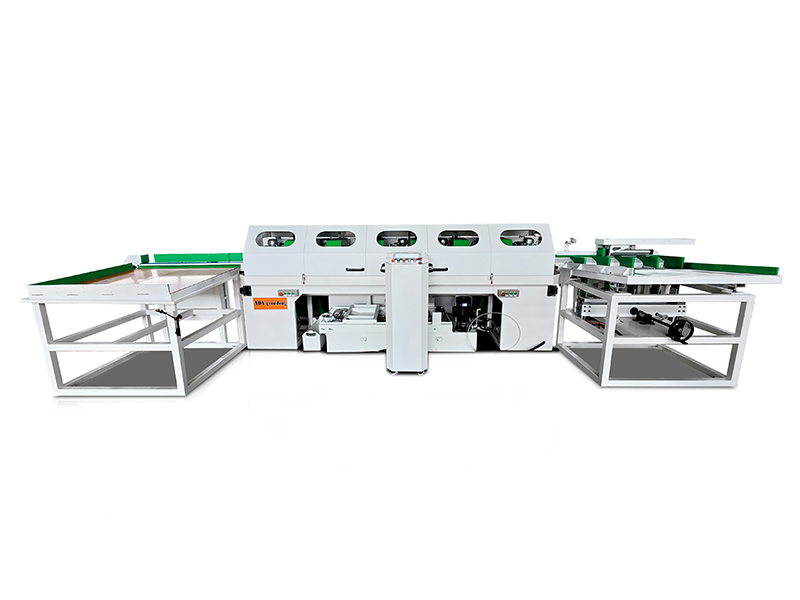

For Straight Tube – The pipe polishing machine can be equipped with 1-10 sets of grinding heads by different requirements. Also, it can be used with automatic loader/unloader to achieve full automation.

A centerless system for pipe polishing is a method that uses a grinding or polishing machine without the need for supporting the pipe at its center. This allows for the efficient and high-quality finishing of pipes, particularly those with varying diameters or complex shapes. These systems are commonly used for applications like handrail polishing, hydraulic shaft finishing, and preparing pipes for plating or painting.

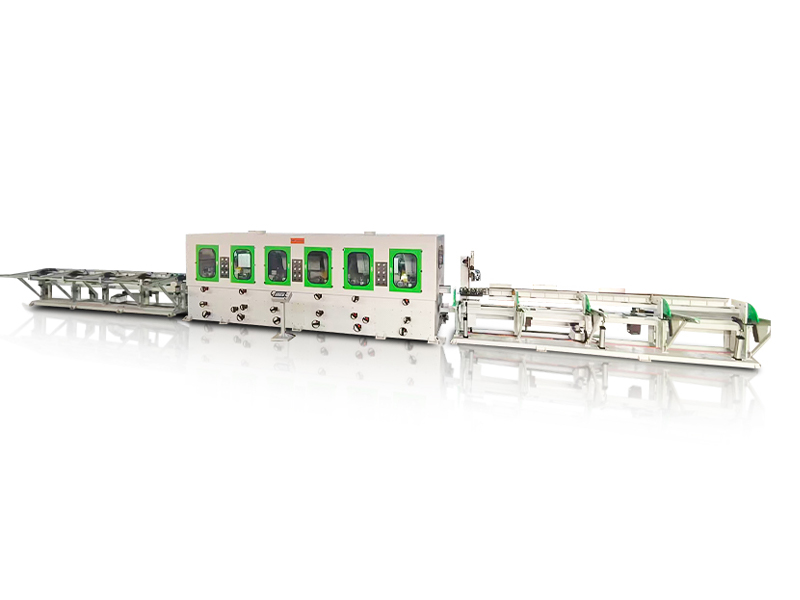

- Planetary System Polishing

Planetary System: How It Works and Its Advantages

Unlike centerless machines, where the tube rotates during the process, the planetary system keeps the tube stationary while abrasive belts rotate around it, performing the polishing.If your goal is to ensure versatility, high productivity, and a flawless, uniform finish on straight, curved, or complex-shaped tubes, the planetary system represents the ADV 108 pipe polisher series, with over 2000 units sold worldwide and its proven planetary technology continuously evolved and refined over 4 product generations, is the market leader combining advanced technology with ergonomic and user-friendly operation, resulting in competitive and reliable solutions.

This characteristic offers numerous benefits:

- Uniform polishing across many geometries: Since the tube does not rotate, the system can consistently process straight, curved, oval, and elliptical tubes, ensuring a homogeneous surface without scratches or flaws.

- Low heat generation: Controlled contact and the absence of tube rotation minimize heat, preserving the properties of the material.

- Minimal vibration: This is essential for achieving a perfect finish, even on long tubes.

- Versatility: Compatible with perforated, conical, straight, or curved tubes, the system easily adapts to different geometries.

- Easy and fast abrasive belt changes: This reduces setup time and increases productivity.

- Smooth and constant feeding: Integrated rollers ensure a continuous and safe tube feed throughout the process, avoiding stops.

- Pipe Polishing Machine3

Classify and describe the test copy…

- Pipe Polishing Machine4

Classify and describe the test copy…

- Pipe Polishing Machine5

Classify and describe the test copy…

- Pipe Polishing Machine6

Classify and describe the test copy…