Share quotes, track production milestones, level-up team benefits together.

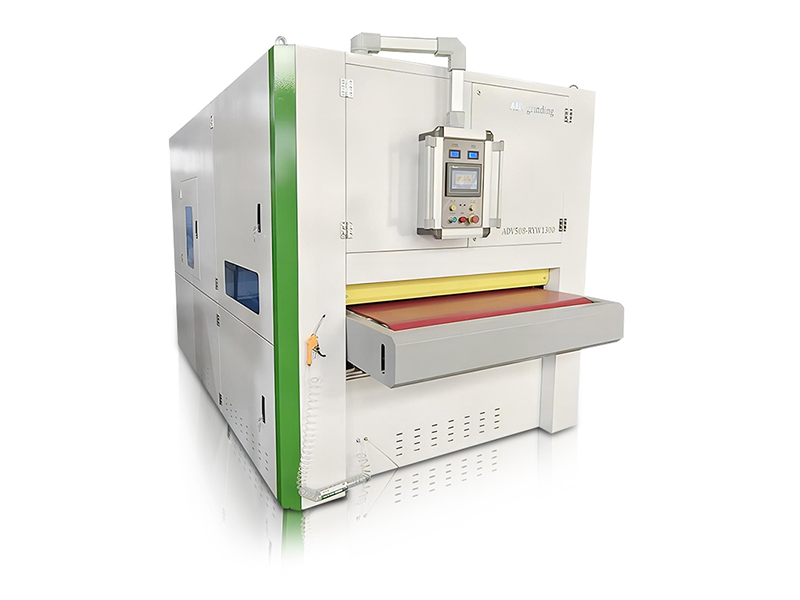

Deburring Machine

Automated Deburring Machines

Tailor-made for your Application

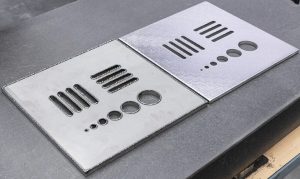

Whether thin sheet metal, heavy plate, small or large burrs – here is the place to find the perfect deburring machine for your sheet metal and heavy plate processing requirements. Regardless if you are cutting with laser, flame, plasma, oxyfuel or for punched parts. Are you looking for a solution that offers you optimal sheet metal quality, high process reliability and low unit costs?

Let us propose the optimal deburring machine for you.

- Deburing of Laser Cut and Punched Parts: Deburr and edge round your laser cut and punched sheet metal with the ADV® 508 Series. Our various models suit different deburring processes and can handle a broad range of materials and dimensions. Learn more about our solutions now!

- Deburring of Plasma & Oxyfuel Cut Parts: Our deburring machines for flame cut parts are unique on the market and famous for their robust design. Oxyfuel cut or plasma cut parts with slag or burrs of more than three millimeters thickness – no problem for our ADV 508-HRW®. Benefit from extreme performance and longevity.

DEBURRING / EDGR ROUNDING / Oxide Removal / Surface Finish

The RW Series deburring machine are machines mainly suitable for deburring, edge rounding with Perfect 2mm radius can be achieved easily + and (directionless) finishing of metal sheet parts, consisting of a grinding belt and 2 brush principles (disc brush + round brush).Customizable models upon different reguests .

- Deburring,descaling,edges rounding and brushing in one feed

- Automatic abrasive compensation and life reminder

- Powerful vacuum adsorption conveyor belt

The RY Series deburrer are machines mainly suitable for deburring, chamfer,rounding and (line) finishing of metal sheet parts, consisting of a grinding belt and a dish brush principle.Vertical burrs removed from stamped, punched, laser, plasma, and water-jet cut parts.Customizable models upon different reguests.

RY Series Combinations that can be customized according to customer requirements : RY / RRY / RYR / RYW

- Used for removing large Burr/Slag or surface polishing effect

- Deburing,descaling,edges rounding and brushing in one feed

- Quick replacement of consumables

The HR Series Deburrer (slag removers) are machines suitable for removing metal slag from steel plate parts.Customizable models upon different reguests .

- Heavy slag removing, deburring, edges rounding and brushing in one feed.

- Hammer set remove heavy slag quickly to reduce labor costs.

- Simple operation and low working cost.

- Powerful Vacuum+magnetic adsorption conveyor belt.

Available in Wet or Dry operation.Finishing brushing and polishing with one feeding,different combination depending on the customer’s needs.High precision grinding,polishing and repairing scratches.

- Deburing,descaling, No.4/HL and polishing in one feed

- Optional washing & drying machine + laminating machine as production line

The Semi-automatics deburring machines suitable for manual finishing of metal sheet parts.

- Multifunctional manual machine for deslagging, deburring, chamfering and finishing.

- Vacuum adsorption worktable, optional magnetic adsorption.

- High damping rubber workbench, ultra-long service life.

- Freely match different materials of consumable to achieve different effects.

- 4 times + faster than manual efficiency.

Grinding Consumables.

Our high quality standards do not only apply to our deburring machines, but to our deburring tools as well. We place great emphasis on the material quality, precision manufacturing and enhanced lifetimes of spare and wear parts. Most often, successful processing depends on the small things. So we offer you only tools that will be able to complete the job correctly, the first time. In our ADV Machinery website, you can find suitable tools and wear parts for your deburring machine.

- Sand belt (for R station)

- Roller brush (for r station)

- Rotary brush (for W station)

- Disc brush (for Y station)

- Slag cleaning hammer / sand block (for H station)